-

Тел.: 86-15176910262

Тел.: 86-15176910262

-

Пошук

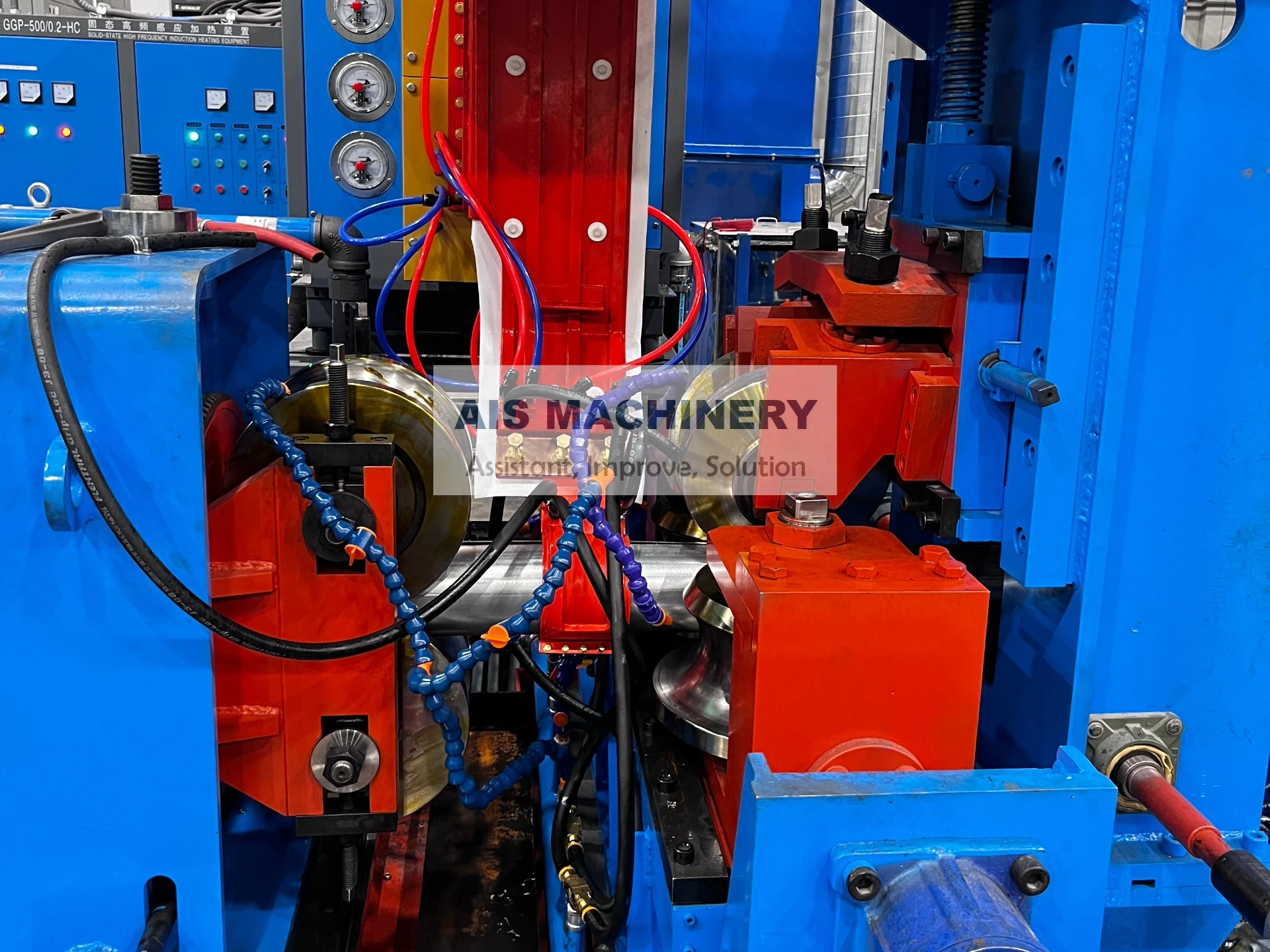

Твердотільний високочастотний зварювальний апарат

A High-Frequency Induction Welding Machine works based on the principle of electromagnetic induction. High-frequency alternating current passes through coils and induces a current in the metal tube at the welding joint. This induces rapid heating at the joint, causing the metal to reach the melting point. The tube ends are then pressed together under pressure, forming a strong weld without the need for additional filler material. This results in an efficient and precise welding process.

Usage

The high-frequency induction welding machine is commonly used in the ERW tube mill to weld the seams of metal tubes. After the tube is formed, it passes through the welding area of the high-frequency induction welding machine, where high-frequency currents heat the seam area to the required welding temperature. Then, the machine’s pressure system presses the heated seam together to complete the high-strength welded joint.

Applications

-

Steel Tube Production: It is primarily used in the production of straight seam welded pipes, suitable for producing various types of steel pipes, especially those requiring high welding quality.

-

Structural Component Welding: Widely used in the welding of structural components like steel beams, supports, and frames.

-

Machinery and Shipbuilding Industries: The high-frequency induction welding machine is commonly used in these industries for efficiently welding metal tubes of different specifications and materials.

-

Energy, Chemical, and Pipeline Industries: The welded tubes are extensively used in pipelines for transporting oil, gas, and chemicals.

Advantages

-

High Welding Speed: The high-frequency induction welding machine offers fast welding speeds, enabling efficient production and reducing the cycle time in large-scale manufacturing.

-

High-Quality Welds: As no filler material is used in the process, the weld quality is excellent with uniform seams and minimal defects.

-

Low Energy Consumption: Since the energy is concentrated in the welding zone, the heat loss is minimal, making it more energy-efficient compared to traditional welding methods.

-

Versatility: It can weld various metals and is suitable for different specifications, offering strong adaptability in welding operations.

-

Ease of Operation: The equipment has a high level of automation, which reduces the complexity of manual operations, improving productivity and reducing human error.

Summary

The high-frequency induction welding machine is a core component of the ERW tube mill, providing high-efficiency, high-quality, and energy-saving welding solutions. It ensures superior weld strength and quality while boosting production efficiency, meeting the demands of various industries.

Надіслати повідомлення

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!