1. Introduction

The steel pipe seam annealing machine is a key piece of heat treatment equipment in welded pipe production lines. It is primarily used to anneal the weld seam of steel pipes after welding, eliminating welding stress, improving microstructure, enhancing corrosion resistance, and extending service life. This equipment is especially suitable for continuous production of stainless steel pipes, titanium alloy pipes, and other high-requirement metal tubes.

2. Working Principle

Induction Annealing Principle:

-

Induction Heating: A high-frequency or medium-frequency power source generates an alternating magnetic field through induction coils, which induces eddy currents in the weld seam area, causing localized heating.

-

Precise Temperature Control: Infrared pyrometers or thermocouples provide real-time closed-loop temperature control to maintain the weld seam at a set annealing temperature (typically 950°C–1100°C).

-

Rapid Cooling: After heating, air or water cooling is applied to rapidly cool the seam, promoting the desired metallurgical transformation.

-

3. Basic Technical Data (Typical)

| Item |

Typical Range |

| Applicable Pipe Diameter |

Φ10 mm ~ Φ168 mm |

| Applicable Wall Thickness |

0.4 mm ~ 5.0 mm |

| Annealing Temperature Range |

850°C ~ 1100°C |

| Output Frequency (Power Source) |

50 kHz ~ 400 kHz (customized per pipe size) |

| Output Power |

30 kW ~ 300 kW |

| Line Speed Compatibility |

10 ~ 120 m/min |

| Heating Zone Length |

100 mm ~ 300 mm (adjustable) |

| Temperature Control Accuracy |

±5°C |

| Cooling Method |

Air cooling / Water cooling |

| Control System |

PLC + HMI (touchscreen interface) |

4. Main Components

-

High- or Medium-Frequency Power Supply – Provides alternating current for induction heating.

-

Induction Coil – Custom-designed (ring or U-type) to surround the weld seam.

-

Support/Guiding Structure – Ensures pipe stability during the annealing process.

-

Temperature Sensor – Infrared or thermocouple sensors for accurate weld temperature feedback.

-

Cooling System – Air or water cooling units to rapidly reduce temperature.

-

PLC Control System – Automates power, temperature, and speed adjustments.

-

Human-Machine Interface (HMI) – Allows the operator to monitor and set parameters.

5. Operation Details

Basic Operation Workflow:

-

Startup

-

Check cooling system, power, air, and water connections.

-

Launch the PLC and input preset parameters: temperature, speed, power level.

-

Heating Start

-

Real-Time Temperature Control

-

Cooling Process

-

Shutdown & Safety

-

After process completion, turn off the power and cooling in sequence.

-

Inspect coils, grounding, and pipes to ensure safe conditions.

-

-

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Вихрострумова машина

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

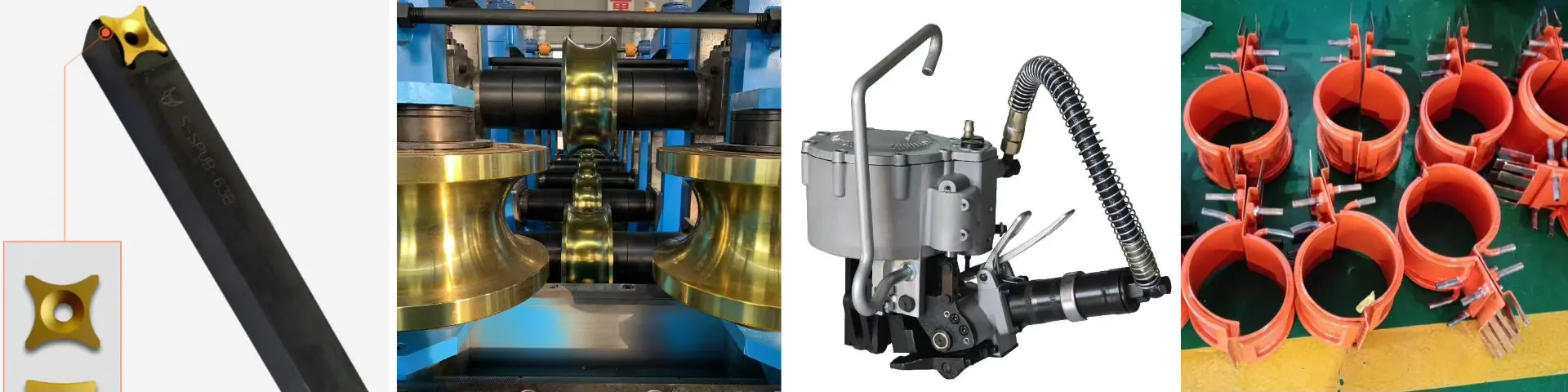

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

- Чому обирають нас?

-

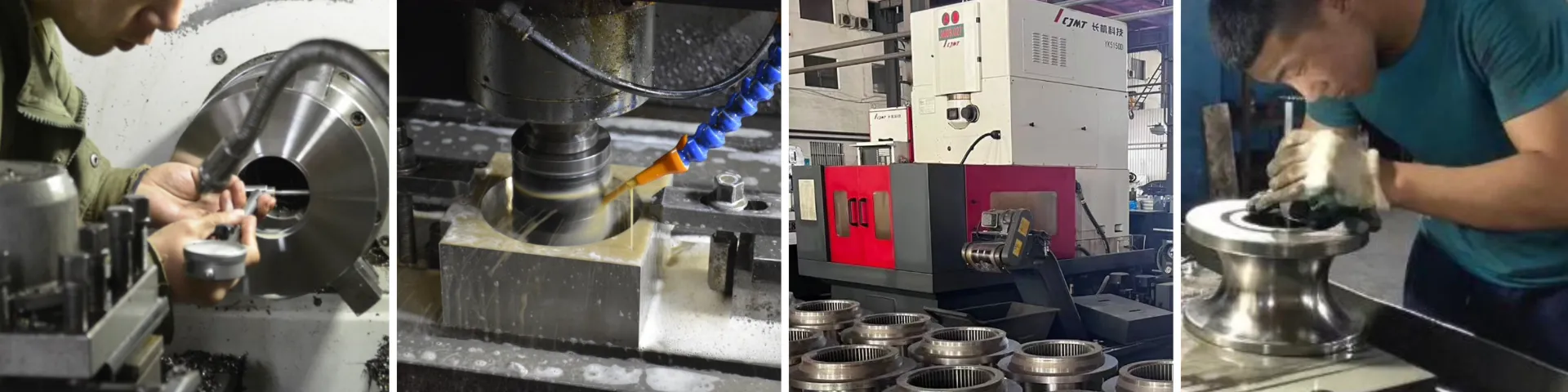

1.Leading Technology, Reliable Quality, Excellent Service! Оптимізований дизайн, вибір високоякісних матеріалів! Гарантія процесу термічної обробки!

-

2.Spiral bevel gear, drum gear coupling and carburization. Загартування зубів шестерень. Привідна система стабільна, ефективна та придатна до носіння з низьким рівнем шуму.

-

3.High precision wear resisting and Long life of toolings. Усі токарні верстати, шпонкові канавки позиціонуються та фрезеруються за допомогою ЧПУ.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

Післяпродажне обслуговування

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5.24 години для відповіді інженера.

- 6. Ваші ділові відносини з нами будуть конфіденційними для будь-якої третьої сторони.

- 7. We welcome customers to visit our factory anytime.

Тел.: 86-15176910262

Тел.: 86-15176910262