Опис товару

1. Overview

Hexagonal Tube Bundling Machine for Solar PV Mounting Structures

The hexagonal tube bundling machine is a specialized automated system designed for the efficient packaging of hexagonal-section steel tubes, commonly used in solar PV mounting structures. This system streamlines the post-forming process by automatically stacking, aligning, and strapping shaped tubes into neat, transport-ready bundles.

2. Working Principle

-

🔧 Key Functions and Features

✅ 1. Automatic Tube Alignment and Stacking

-

Incoming tubes from the roll forming line are conveyed and precisely aligned.

-

Specially designed V-shaped or contour-adaptive platforms ensure accurate positioning of hexagonal profiles without deformation.

-

The machine can handle various lengths (typically 4–7 meters) and sizes of hex tubes.

✅ 2. Intelligent Layered Stacking System

-

A programmable hydraulic or servo lifting table stacks tubes layer by layer.

-

Sensors and PLC control systems ensure consistent stacking height and spacing.

-

Optional weighing and counting modules can be integrated.

✅ 3. Automatic Strapping & Bundling

-

Once a complete bundle is formed, the system initiates the strapping process using steel or PET straps.

-

Straps are automatically fed, tensioned, locked (with heat or mechanical seals), and cut.

-

Bundles are secured with 2–4 straps, depending on tube length and customer requirements.

✅ 4. Customizable Bundle Shape

-

Supports hexagonal, square or custom bundle shapes to match container loading and warehouse space.

-

Optional corner protection insertion or shrink-wrapping module available.

3. Main Technical Parameters (Example)

| Parameter |

Specification |

| Tube Shape |

Hexagonal (or optional square) |

| Tube Size Range |

Width across flats: 30–127 mm |

| Tube Length |

6000–13000 mm |

| Bundle Size |

Customizable (e.g., 300x300 mm) |

| Strapping Material |

PET / Steel Band |

| Strapping Count |

2–4 straps per bundle |

| Power Supply |

380V, 50Hz, 3 Phase (customizable) |

| Control System |

PLC + HMI Touch Screen |

| Optional Add-ons |

Weighing, Labeling, Barcode system |

4. Main Components

-

High Efficiency: Fully automated bundling reduces manual labor and improves consistency.

-

Profile Protection: Tailored holding and lifting components prevent dents or scratches on hex tubes.

-

Flexible Integration: Can be directly connected to the end of a solar frame roll forming line.

-

Smart Operation: PLC control with real-time diagnostics and error alerts.

-

Export-Ready Bundles: Clean, tight bundles suitable for container loading and long-distance transport.

-

6. Maintenance & Inspection

| Item |

Frequency |

Description |

| Seal Inspection |

Daily |

Replace worn or aged seals |

| Filter Cleaning |

Weekly |

Ensure pump intake is free from debris |

| Pressure Sensor Calibration |

Monthly |

Check accuracy or replace if needed |

| Hydraulic Oil Change |

Every 6 mo. |

Ensure smooth operation of hydraulics |

| Safety System Check |

Daily |

Confirm emergency stop, relief valves |

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Вихрострумова машина

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

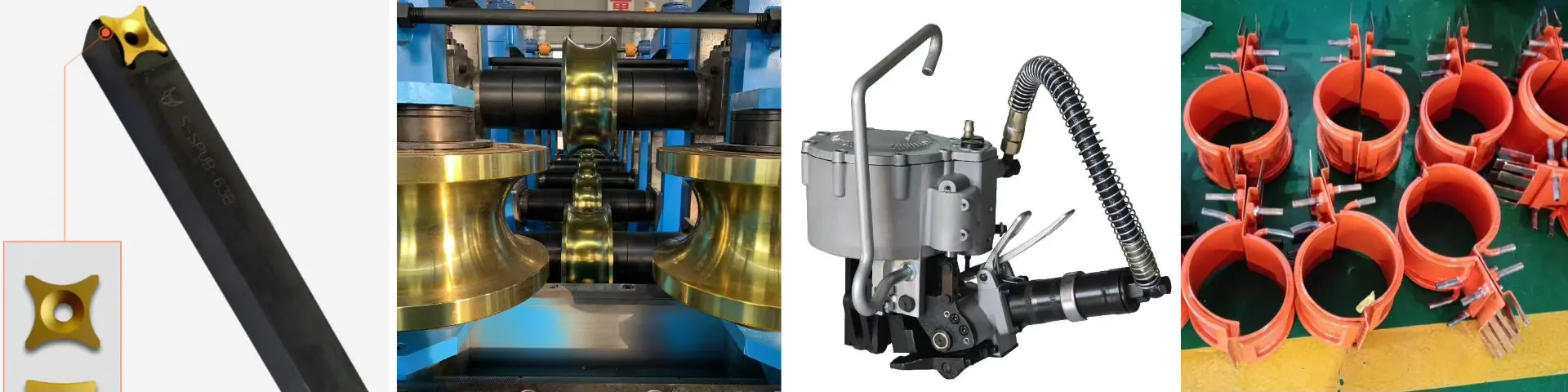

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

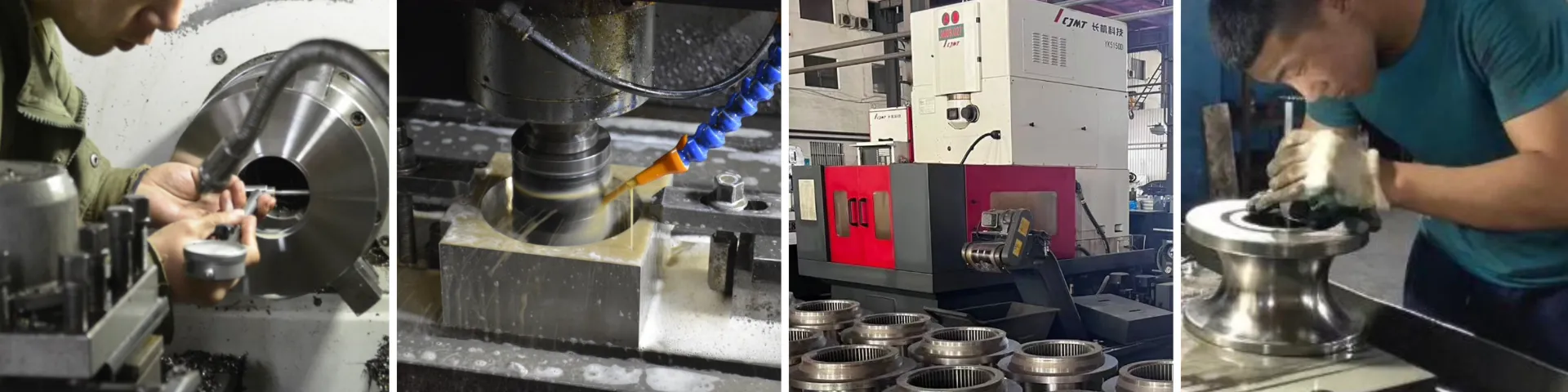

- Чому обирають нас?

-

1.Leading Technology, Reliable Quality, Excellent Service! Оптимізований дизайн, вибір високоякісних матеріалів! Гарантія процесу термічної обробки!

-

2.Spiral bevel gear, drum gear coupling and carburization. Загартування зубів шестерень. Привідна система стабільна, ефективна та придатна до носіння з низьким рівнем шуму.

-

3.High precision wear resisting and Long life of toolings. Усі токарні верстати, шпонкові канавки позиціонуються та фрезеруються за допомогою ЧПУ.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

Післяпродажне обслуговування

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5.24 години для відповіді інженера.

- 6. Ваші ділові відносини з нами будуть конфіденційними для будь-якої третьої сторони.

- 7. We welcome customers to visit our factory anytime.

Тел.: 86-15176910262

Тел.: 86-15176910262