1. Introduction

The Steel Coil Transfer Car is a type of material handling equipment designed for transporting steel coils or heavy loads within industrial workshops. It features high load capacity, smooth operation, and reliable safety. It is widely used in metallurgy, steel pipe manufacturing, warehousing, and related industries.

2. Main Components

-

Car Body: Welded high-strength steel structure for heavy-duty load bearing

-

Electrical Control System: PLC control with wireless remote or manual operation

-

Drive Unit: Motor and reducer combination, often equipped with a frequency inverter

-

Wheel System: Rail-mounted or rubber wheels (non-rail type)

-

Power Supply Options:

-

Safety Devices: Limit switches, audible and visual alarms, emergency stop button, anti-collision system

-

Steel Coil Support Structure (optional): V-frame or hydraulic lifting frame to prevent coil rolling

-

3. Technical Parameters (Example)

| Item |

Parameter Example |

| Load Capacity |

5~150 tons (customizable) |

| Travel Speed |

0~20 m/min (adjustable) |

| Power Supply |

Battery/Conductor Rail/Cable Reel |

| Control Method |

Manual + Remote + Auto |

| Minimum Turning Radius |

Depending on vehicle size |

| Working Temperature |

-20°C ~ +50°C |

| Surface Treatment |

Sandblasting + Anti-rust Paint |

4. Working Principle

The drive system propels the wheels to move forward or backward, enabling the steel coil to be transferred between production processes. It can be controlled via remote or central control system, with accurate positioning based on travel setup. Battery-powered versions may include auto-charging features.

5. Application Scenarios

-

Transfer between coil storage and production lines

-

Coil feeding system in pipe mills

-

Pre- and post-heat treatment transport

-

Material handling in automated warehouse systems

-

6. Operating Instructions

-

Pre-operation check: power status, wheel condition, obstacle clearance

-

Power on control unit: operate via panel or remote controller for start, stop, speed adjustment, and direction change

-

Position coil centered in the V-frame during loading

-

Do not overload or allow personnel on board during movement

-

Cut off power or return to charging station after use

7. Maintenance

-

Weekly inspection of motor, wheel axle, and fasteners

-

Regular lubrication of transmission parts

-

For battery-powered units, check charge level and terminal corrosion regularly

-

Keep the control box dustproof and moisture-proof

-

Periodically calibrate limit switches

8. Safety Instructions

-

Operators must receive proper training

-

Overloading or high-speed operation on inclines is strictly prohibited

-

Check all safety alarm devices before operation

-

Power must be shut off immediately in case of any abnormal situation

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Вихрострумова машина

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

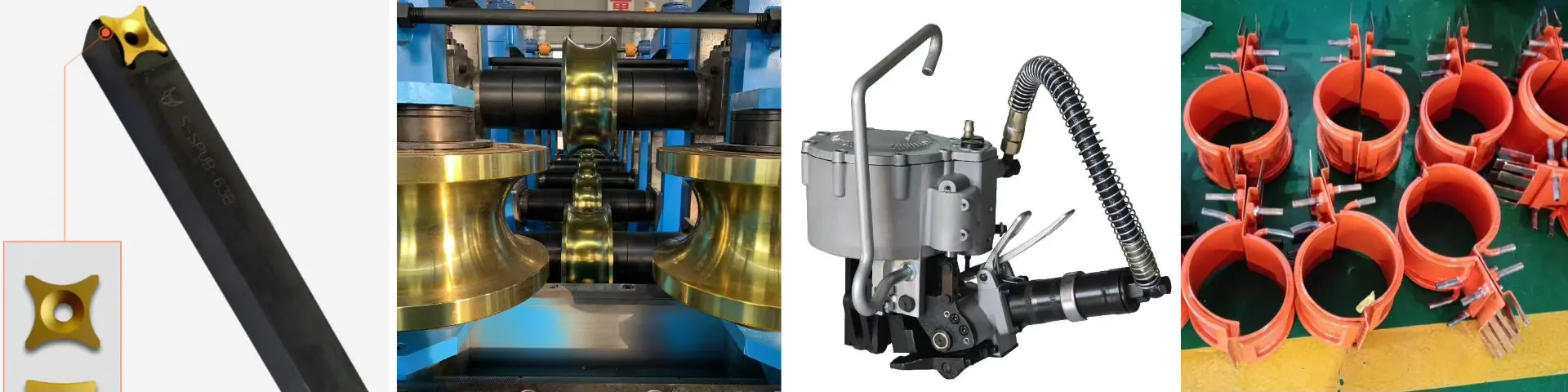

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

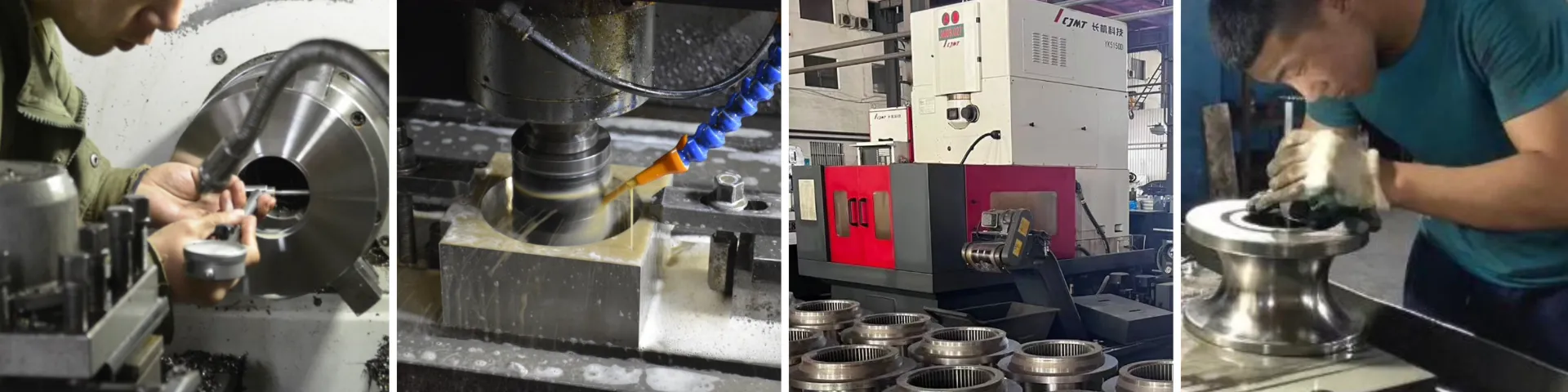

- Чому обирають нас?

-

1.Leading Technology, Reliable Quality, Excellent Service! Оптимізований дизайн, вибір високоякісних матеріалів! Гарантія процесу термічної обробки!

-

2.Spiral bevel gear, drum gear coupling and carburization. Загартування зубів шестерень. Привідна система стабільна, ефективна та придатна до носіння з низьким рівнем шуму.

-

3.High precision wear resisting and Long life of toolings. Усі токарні верстати, шпонкові канавки позиціонуються та фрезеруються за допомогою ЧПУ.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

Післяпродажне обслуговування

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5.24 години для відповіді інженера.

- 6. Ваші ділові відносини з нами будуть конфіденційними для будь-якої третьої сторони.

- 7. We welcome customers to visit our factory anytime.

Тел.: 86-15176910262

Тел.: 86-15176910262