-

Tel:86-15176910262

Tel:86-15176910262

-

Search

ERW Tube Mill Process High-Speed, Precision Manufacturing Solutions

Mag . 30, 2025 02:27

- Understanding the Fundamentals of ERW Tube Production

- Technological Breakthroughs in Modern Tube Mills

- Performance Metrics: Industry Leaders Compared

- Custom Engineering for Specific Manufacturing Needs

- Operational Excellence Through Advanced Control Systems

- Real-World Implementations Across Industries

- Future-Proofing Your ERW Tube Manufacturing

(erw tube mill process)

Understanding the Fundamentals of ERW Tube Production

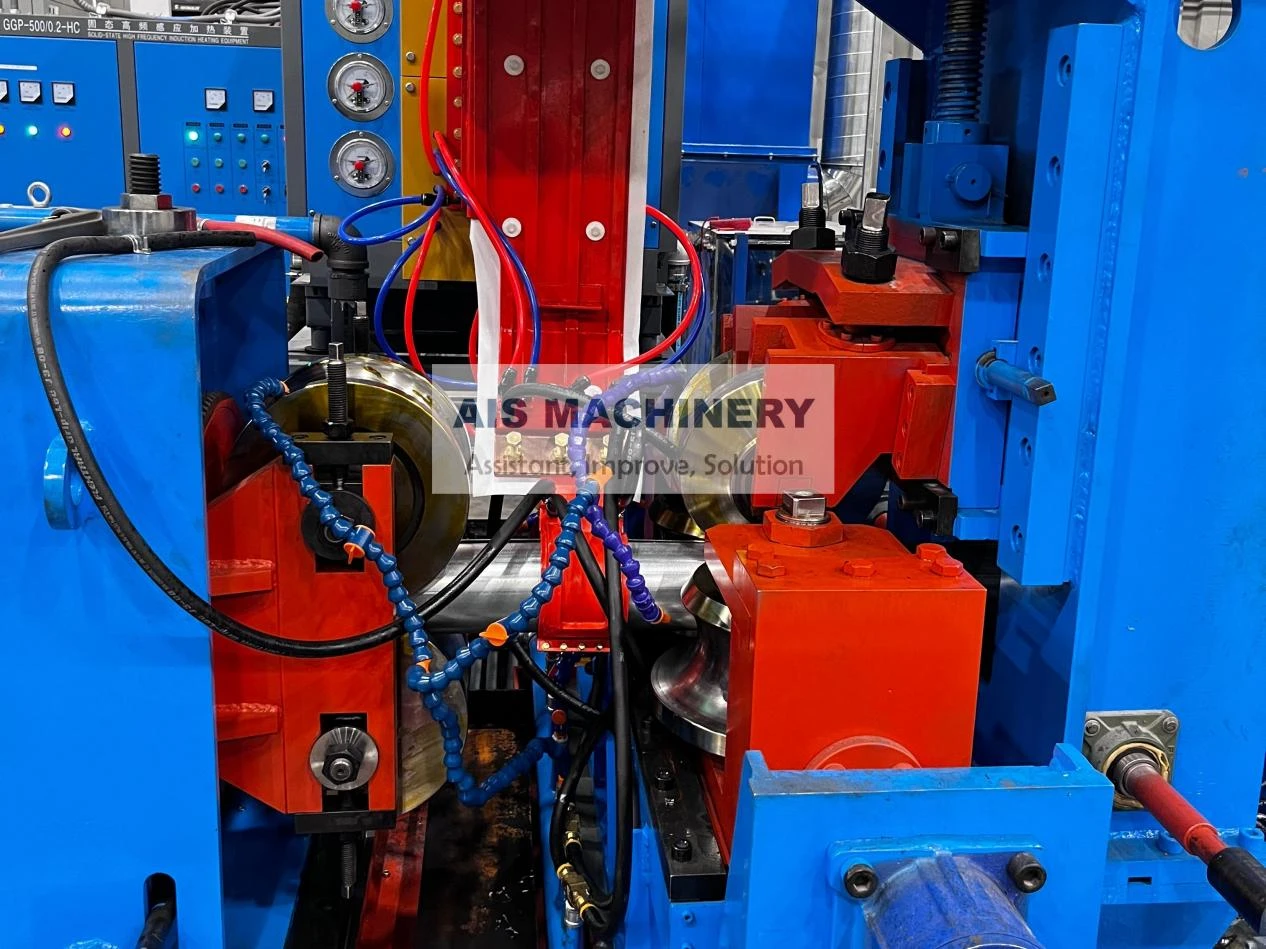

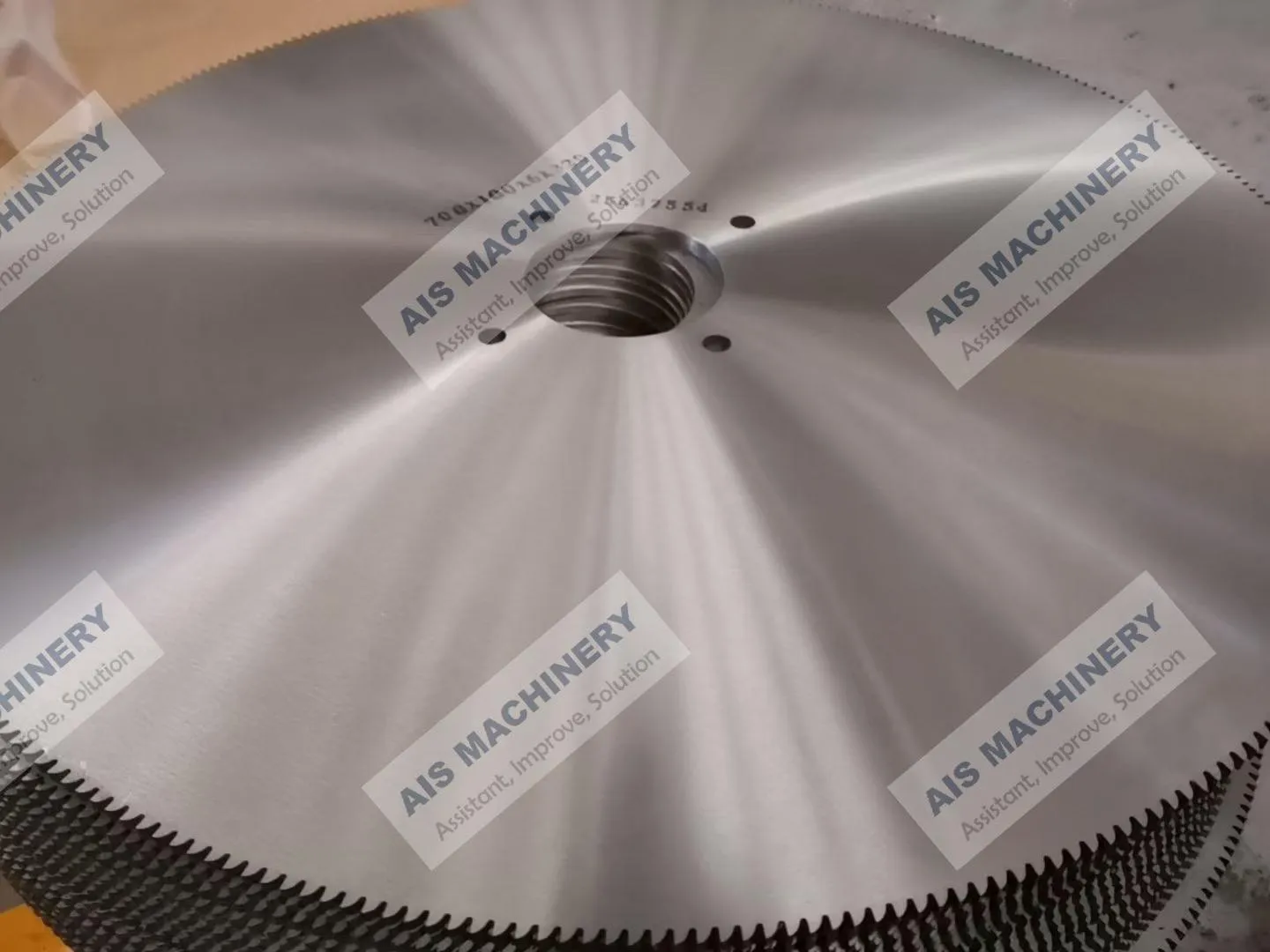

The ERW tube mill process transforms coiled steel into precision tubular products through 12-27 sequential forming stages. Modern mills achieve dimensional tolerances of ±0.10mm on wall thickness, with production speeds exceeding 400 meters/minute. Key components like the high-frequency welder and automated sizing system ensure consistent output across diameters ranging from 10mm to 610mm.

Technological Breakthroughs in Modern Tube Mills

Recent advancements feature:

- AI-powered defect detection systems (99.98% accuracy)

- Energy-efficient induction heating (35% power reduction)

- Closed-loop thickness control (±0.025mm variance)

These innovations enable 24/7 operation with ≤0.5% material waste, significantly outperforming traditional mills' 3-5% scrap rates.

Performance Metrics: Industry Leaders Compared

| Manufacturer | Max Speed (m/min) | Diameter Range (mm) | Energy Use (kWh/ton) | MTBF (hours) |

|---|---|---|---|---|

| X-Tech MillPro | 427 | 12-508 | 58 | 2,150 |

| Y-Steel Master | 385 | 15-610 | 63 | 1,800 |

| Z-Precision Tube | 455 | 10-355 | 52 | 2,400 |

Custom Engineering for Specific Manufacturing Needs

Specialized configurations address:

- API-standard oil/gas pipes (J55/K55 grades)

- Automotive structural components (HSLA steels)

- Architectural tubing (A500 Grade C)

Custom tooling packages reduce changeover time to 18-22 minutes versus standard 45-minute industry averages.

Operational Excellence Through Advanced Control Systems

Integrated PLC systems monitor 120+ parameters simultaneously, including:

- Weld seam temperature (1,250-1,450°C range)

- Roll forming pressure (850-2,200 kN)

- Strip alignment accuracy (±0.05mm)

Real-World Implementations Across Industries

A recent automotive application achieved:

- 23% weight reduction in chassis components

- 18-month ROI through energy savings

- AS9100-certified production for aerospace clients

Future-Proofing Your ERW Tube Manufacturing

As global demand for precision tubing grows at 4.8% CAGR (Market Research Future 2023), upgrading your tube mill process ensures competitiveness. Modern ERW systems now integrate with Industry 4.0 platforms, enabling predictive maintenance that reduces downtime by 40% and extends equipment lifespan by 7-10 years.

(erw tube mill process)

FAQS on erw tube mill process

Q: What is the ERW tube mill process?

A: The ERW (Electric Resistance Welding) tube mill process involves forming flat steel strips into cylindrical shapes and welding the edges using high-frequency electrical current to produce seamless-like tubes.

Q: What are the main stages of a tube mill process?

A: Key stages include uncoiling the steel strip, forming it into a tube, welding the seam, cooling, sizing, and cutting the tube to required lengths.

Q: How does ERW differ from other tube mill processes?

A: Unlike seamless or submerged arc welding (SAW) processes, ERW uses high-frequency electrical resistance to weld edges without filler material, ensuring faster production and cost efficiency.

Q: Where can I find a detailed tube mill process PDF guide?

A: Many manufacturers and industry websites provide free downloadable PDFs outlining ERW tube mill workflows, equipment specifications, and quality standards.

Q: What factors affect weld quality in an ERW tube mill process?

A: Critical factors include strip edge quality, welding current frequency, pressure during forming, and post-weld heat treatment to ensure structural integrity.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!