-

Tel:86-15176910262

Tel:86-15176910262

-

Ricerca

PRODOTTO

FORNITORE DI LAMINATOI PER TUBI ERW, LINEE DI TAGLIO A TAGLIO, LINEE DI TAGLIO A MISURA

CHI SIAMO SONO ?

CHI SIAMO?

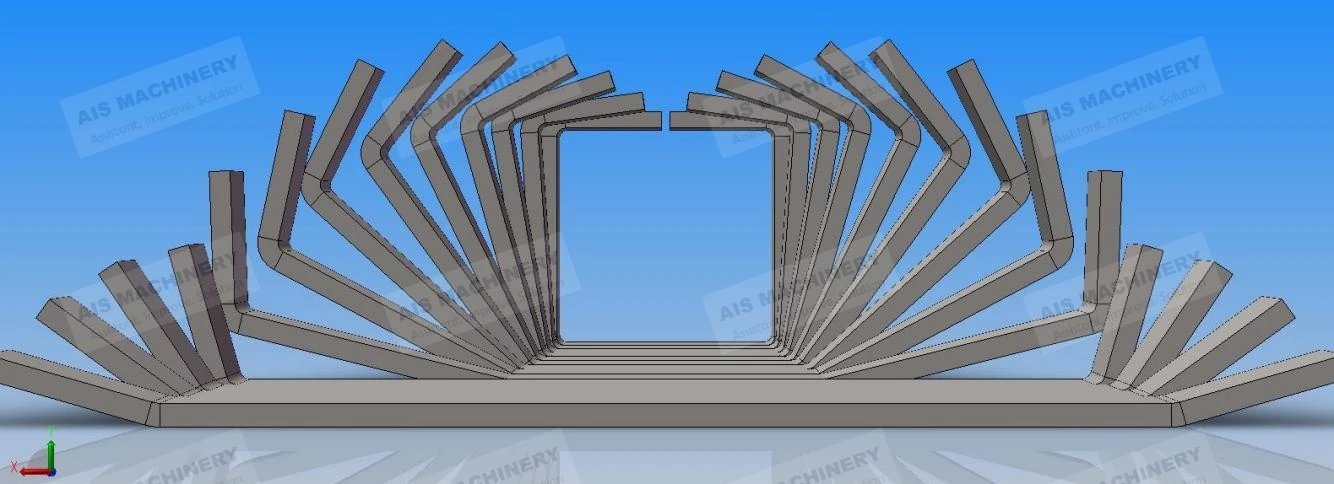

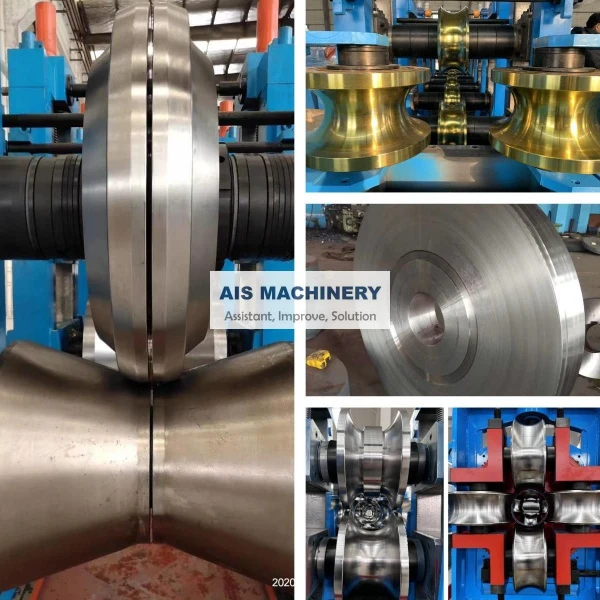

Hebei AIS Machinery Equipment, situata nella città di Shijiazhuang, provincia di Hebei, Cina CN. La fabbrica ha ottenuto la certificazione ISO, CE e SGS ed è un fornitore professionale di macchine per laminazione tubi ERW, macchine per la produzione di tubi saldati longitudinalmente ad alta frequenza, laminatoi per tubi API, macchine per la produzione di tubi con saldatura a induzione FFX, laminatoi per tubi quadrati con formatura diretta DFT, macchine per laminazione a freddo, macchine per laminazione tubi multifunzionali, linee di taglio di bobine di acciaio, linee di taglio a misura e altri pezzi di ricambio.

Oggi, AIS Machinery si impegna a fornire prodotti e servizi personalizzati e affidabili. Con un gruppo di ingegneri professionisti e tecnici esperti per soddisfare le attuali richieste del mercato con prodotti e servizi affidabili. Fabbrica con controllo rigoroso della progettazione ingegneristica, componenti affidabili e ispezioni di qualità per garantire attrezzature di finitura di qualità. Abbiamo anche esperienza in progetti chiavi in mano. AIS Machinery serve più di 100 aziende fornendo attrezzature e soluzioni complete.

INFORMAZIONI SU AIS

CASO DOCUMENTAZIONE

Produzione vantaggio

Invia un messaggio

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!