1. Overview

The End Facer and Chamfer Machine is a specialized finishing device used in welded pipe production lines. Its main function is to perform end-facing and outer chamfering on both ends of steel pipes after cutting. This ensures smooth, clean, and dimensionally accurate pipe ends, ideal for high-precision assembly such as butt welding or flange connection.

2. Working Principle

After the pipe is transported into the working station, the clamping system firmly fixes it in position. The cutting head, driven by the main spindle, rotates and performs simultaneous end-facing and chamfering. The chamfer angle and depth are adjustable. After processing, the clamp releases the pipe, and it exits the station automatically.

-

3. Technical Specifications (Example)

| Item |

Specification |

| Pipe Diameter Range |

Ø48mm – Ø610mm (customizable) |

| Wall Thickness Capacity |

≤20mm (depending on material) |

| Pipe Length Range |

300mm – 12,000mm |

| Chamfer Angle |

30°, 37.5°, 45° (adjustable) |

| Cutter Spindle Speed |

50 – 300 rpm (variable speed) |

| Drive Type |

Hydraulic or servo motor |

| Control System |

PLC + HMI touch screen |

| Efficiency |

10–30 pipes/hour (depending on pipe size) |

| Power Supply |

3-phase 380V / 50Hz |

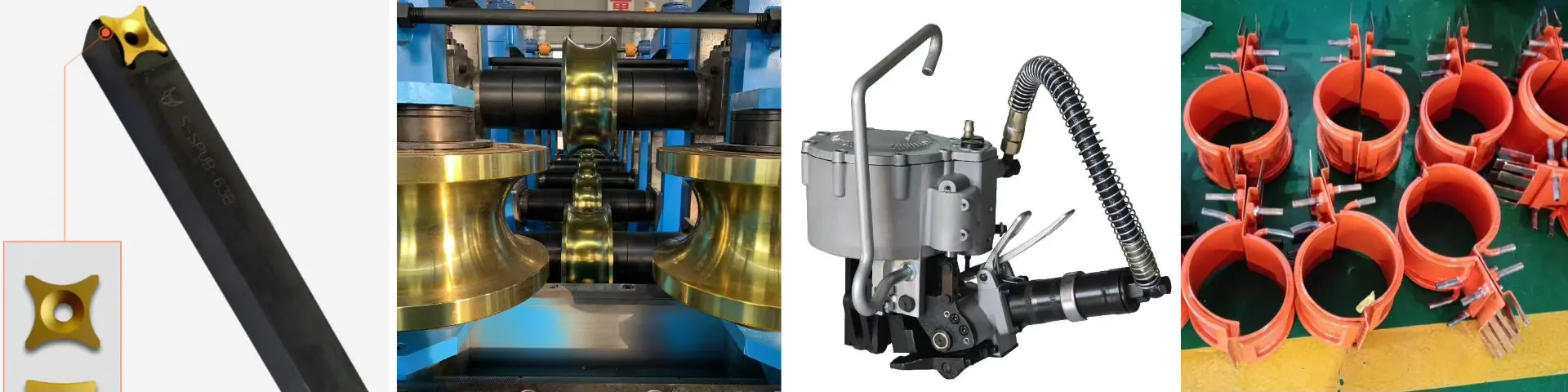

4. Main Components

-

Machine Base – Heavy-duty base to support the full structure.

-

Clamping System – Hydraulic system to securely hold pipes.

-

Main Spindle & Cutter Head – Performs facing and chamfering.

-

Cutting Tools – Replaceable facing and chamfer inserts.

-

Servo Feed System – Precisely moves pipes into position.

-

Chip Removal System – Handles metal chip discharge.

-

Control Cabinet – Includes PLC, HMI, and safety interlocks.

-

5. Operation Process

-

Check the equipment and tool condition.

-

Load the pipe onto the infeed rail.

-

Engage the clamping system.

-

Start the cutting system to face and chamfer the pipe.

-

Once complete, release the clamp and eject the pipe.

-

Repeat for the next pipe.

6. Maintenance Guidelines

-

Clean tools and chip area after each shift.

-

Check hydraulic oil and lubrication levels regularly.

-

Inspect clamps and tools monthly.

-

Calibrate PLC and sensors periodically.

-

Avoid overloading or using damaged tools.

7. Application Scope

Ideal for pipelines used in oil & gas, pressure vessels, structural applications, and other industries requiring high-precision pipe ends.

-

-

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Macchina a correnti parassite

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

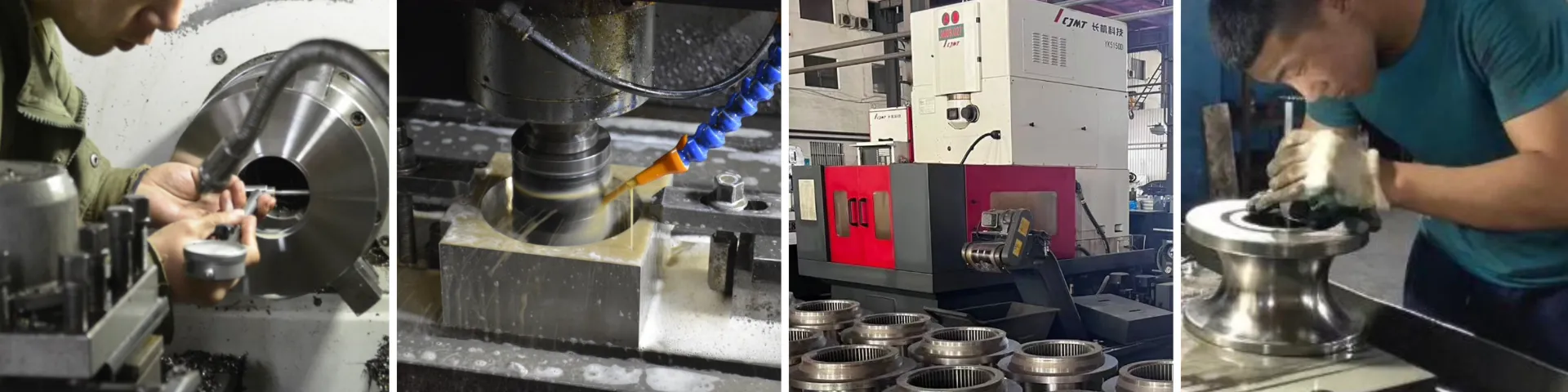

- Perché sceglierci?

-

1.Leading Technology, Reliable Quality, Excellent Service! Design ottimizzato, materiali di alta qualità selezionati! Garanzia del processo di trattamento termico!

-

2.Spiral bevel gear, drum gear coupling and carburization. Tempra dei denti degli ingranaggi. Sistema di azionamento stabile, efficiente e indossabile con rumorosità ridotta.

-

3.High precision wear resisting and Long life of toolings. Tutti i torni e le sedi per chiavette sono posizionati e fresati tramite CNC.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

Servizio post-vendita

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5.24 ore per la risposta del tecnico.

- 6. Il tuo rapporto commerciale con noi sarà riservato a terzi.

- 7. We welcome customers to visit our factory anytime.

Tel:86-15176910262

Tel:86-15176910262