-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Solar Piles

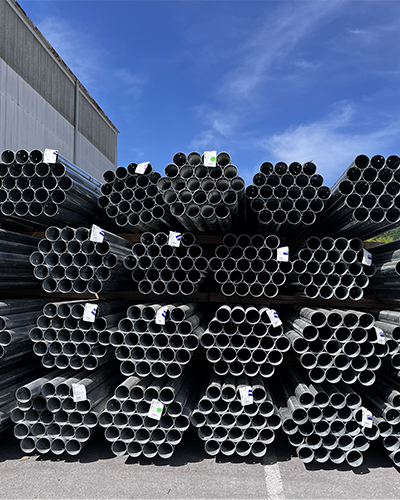

As solar projects become more popular in these coming years, steel pipe piles are widely use at the construction of renewable energy projects such as wind and solar .Steel piles are strong and easy to drive through a wide variety of soil conditions.Ease of transportation due to ability to bundle and stack efficently. We also have in-depth cooperation with world-renowned solar installation manufacturers to occupy a favorable position in the market. AIS MACHINERY products can show you how to get the best solutions for your Solar Farm project. We take pride in our extensive customer support, providing you with the highest level of service and quality at the lowest possible cost. Hebei AIS Machinery's equipment is used to produce solar brackets, solar piles, which are used to install solar panels and are well received by customers. Hebei AIS Machinery also has other types of solar piles shapes suitable for different countries and regions. Welcome to call for consultation and purchase. In the leading industry of Opticals, IT, Semiconductors, Shipbuilders, and Automobile related, we do our best at not only development and manufacturing of the wide range products consisting mainly of Horizontal boring machines, Bridge mills, Vertical turning lathe, but also expansion of stock business, such as maintenance and retrofit. We strain "CRAFTMANSHIP" and aim at the new quantum leap in the 21st Century.

Natural Gas And Liquid Transmission

ERW steel pipes are commonly used in the transmission of natural gas from production sites to distribution centers and end-users. These pipes can withstand high pressure and offer excellent resistance to corrosion, making them ideal for long-distance gas transmission. Carbon steel pipes, also known as CS pipes, are used for water supply. They are made of an iron alloy that contains small amounts of carbon and other elements, which gives them better properties than pure iron. These pipes are mainly used to transport tap water, industrial water, and agricultural irrigation water.This 10inch Carbon steel ERW Pipe Making equipment has been running for nearly 10 years. It can produce round erw pipes up to 273mm and square pipes of 200x200mm. In the years when Africa has rapidly developed infrastructure, large-diameter steel pipes are in short supply in the local market. Customers here work overtime to produce, and buyers waiting to load steel pipes on the other side wait next to the equipment. The production is sold and taken away very fast. The business is in full swing. This customer is also very business-minded. He bought this equipment many years ago when people did not have the courage to use large equipment, so the money he earns now is also unique. We have a variety of technologies to choose from for large-diameter steel pipe equipment, such as FFX and DFT. FFX can save customers 40% of mold costs and reduce the time customers spend changing molds. A set of DFT technology molds can produce a variety of square and rectangular tubes without changing molds, saving time and effort. It is simply a dream machine for customers. Hebei AIS Machinery also has equipment quick change systems, etc., which are suitable for the production and processing of various tubes. Welcome to call for consultation.

Automotive, Construction,Furniture.

Electric Resistance Welded (ERW) tubes are pivotal across many industries, thanks to their precision, strength, and adaptability. The industrial applications of ERW tubes range from automotive to construction, where they provide reliable performance and contribute to enhanced operational efficiency. Their lightweight yet durable nature also supports sustainability efforts in industries like renewable energy and furniture design. As you explore their use further, you’ll discover ERW tubes have surprising applications, even in unexpected areas, solidifying their role in modern industry.

Related Products

Related News