-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Tube Mill Machine Compose

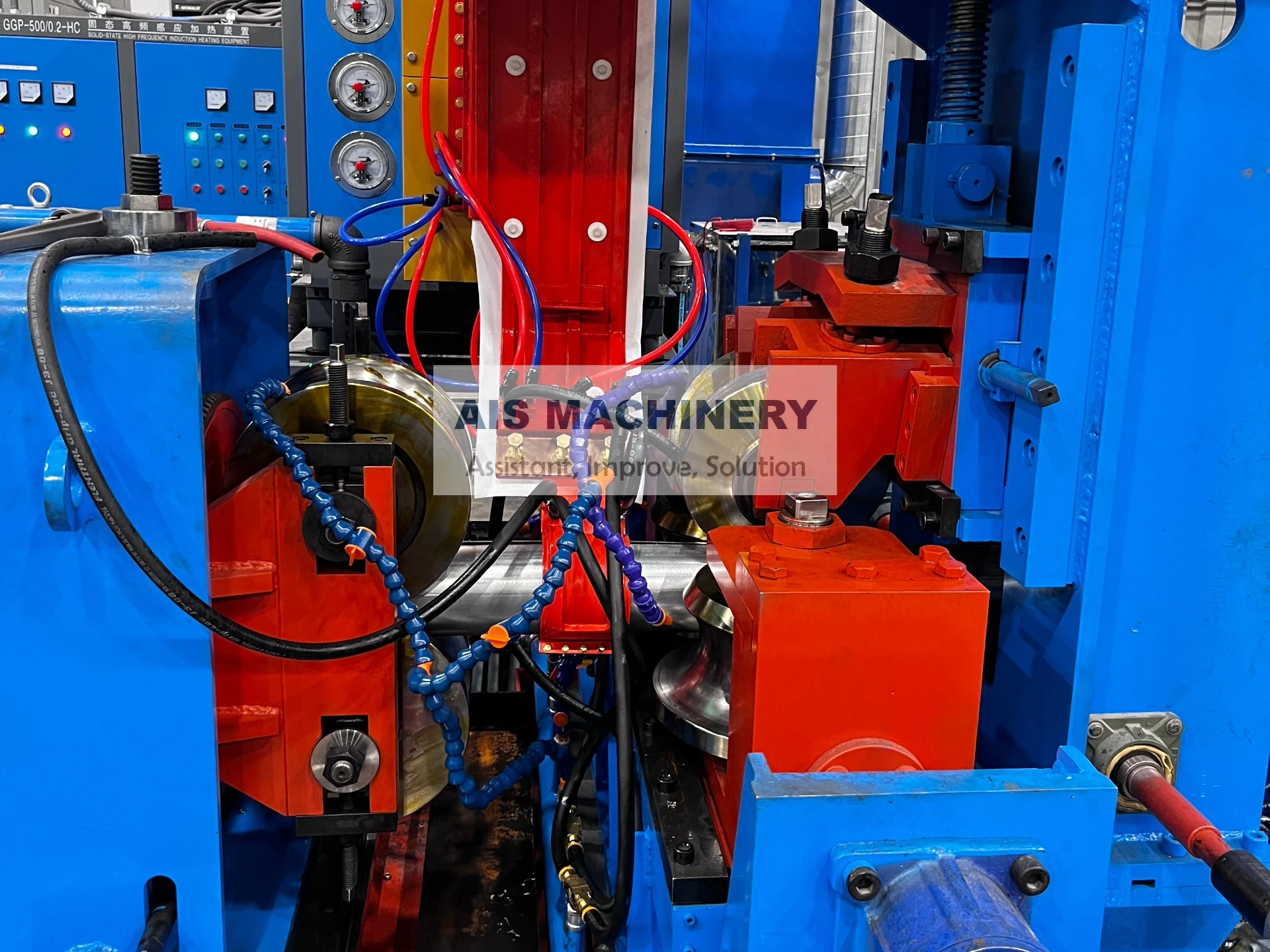

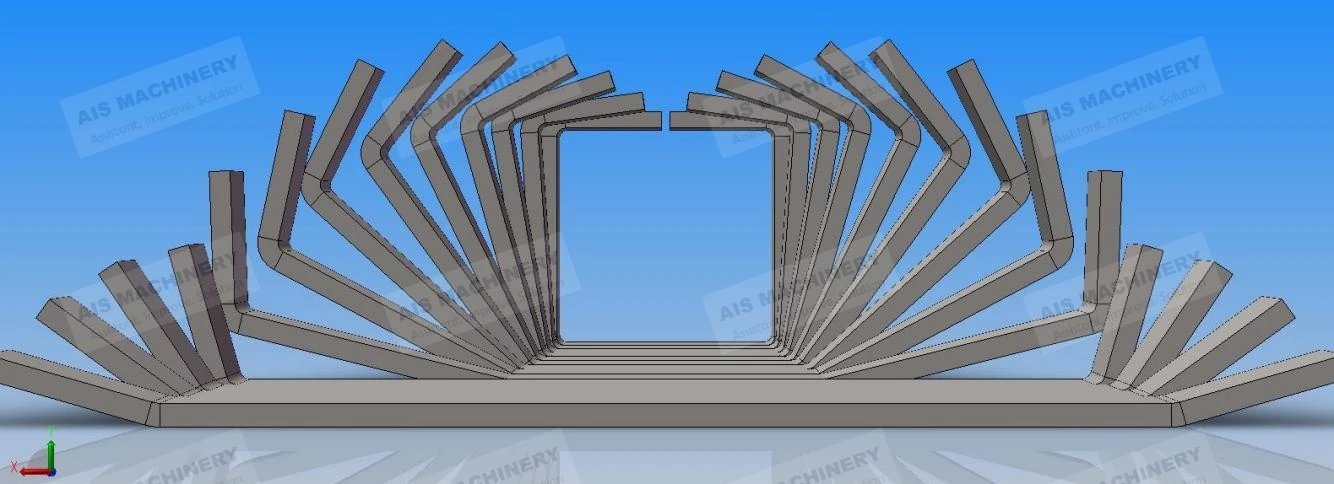

Steel Pipe Making Machine is an efficient production system consisting of multiple stages to ensure continuous and high-quality pipe manufacturing. In the initial phase, the Uncoiler unwinds the steel coil, and then the Butt Shear and Welder machine connects the steel strip’s edges, enabling uninterrupted production. The Accumulator Loop system serves as a buffer, ensuring a stable supply of material throughout the process. In the forming and sizing section, Roller Toolings precisely adjust the steel strip, gradually shaping it into a pipe. Afterward, the High-Frequency Induction Welding Machine performs precise welding on the pipe seam to ensure strength and quality. Finally, the Cut-off Saw cuts the formed pipe into preset lengths, completing the processing. These machines work in unison, forming a highly efficient and stable straight seam welded pipe production line that meets high precision and high-efficiency manufacturing requirements, widely used across various industries.

How Are Steel Tubes Manufactured?

Steel tubes are manufactured through several processes, with the most common methods being extrusion, seamless tube production, and welded tube production. The production method selected typically depends on the intended application and the specific properties required for the final product.In the seamless tube production process, a solid billet of steel is first heated to high temperatures and then pierced to form a hollow tube. The tube is then elongated and reduced in diameter through a series of processes called extrusion and rotary piercing. The tube is continuously reduced in size by passing it through a set of rollers, followed by cooling and straightening operations. This method produces high-strength steel tubes with uniform thickness, ideal for industries that require tubes with exceptional strength and resistance to pressure, such as in the oil and gas, automotive, and construction industries.

In the welded tube production process, a flat steel strip or coil is first uncoiled and fed into a tube mill, where it is passed through a series of rollers that bend it into a cylindrical shape. The edges of the strip are then welded together using high-frequency or laser welding techniques to form a continuous tube. The tube is then cooled, straightened, and cut to the required lengths. Welded tubes are often used in structural applications, plumbing, and manufacturing, as they can be produced in a wide range of sizes and thicknesses at a relatively lower cost compared to seamless tubes.Both methods are followed by various finishing processes such as heat treatment, surface polishing, and coating, depending on the specific requirements of the steel tubes. The result is a high-quality, durable product suited for a wide range of applications across multiple industries.

What Is Tube Mill Machine?

A tube mill machine is a specialized industrial equipment used to manufacture tubes and pipes from various metals, such as steel, stainless steel, or aluminum. The machine operates through a continuous process that shapes a flat metal strip or coil into a tubular form by using a series of rollers, welding systems, and finishing units. The process starts by feeding a metal coil into the tube mill, where it is uncoiled, straightened, and aligned. The metal strip is then progressively formed into a tube by passing through a series of forming rollers.These rollers gradually bend the edges of the metal strip until they meet, creating a cylindrical shape. The next step involves welding the edges of the strip together to form a seamless tube. This is typically done using high-frequency electric resistance welding (ERW) or sometimes laser welding, depending on the material and desired specifications. Once the tube is welded, it passes through sizing rollers that adjust the diameter and wall thickness of the tube to ensure it meets precise specifications.

The tube is then straightened to eliminate any warping and is cut into the desired lengths by an automatic cutting system. Throughout the entire process, the tube mill ensures that the tube maintains high precision and consistency in terms of dimensions and surface finish. One of the key advantages of tube mill machines is their ability to produce tubes at high speeds with minimal material waste, making them highly efficient and cost-effective for large-scale production. These machines can produce tubes in various shapes, including round, square, rectangular, or custom profiles, depending on the application requirements.Additionally, tube mill machines can be adapted to process a wide range of materials, including carbon steel, stainless steel, and aluminum, making them versatile and suitable for a variety of industries. Tube mills are commonly used in industries such as construction, automotive, energy, and manufacturing, where high-quality, durable tubes and pipes are essential. The tubes produced by these machines are used in a wide range of applications, including fluid and gas transportation, structural components, and mechanical parts.

The ability to produce tubes with tight tolerances, consistent quality, and a smooth surface finish makes tube mill machines essential for meeting the demands of industries that require high-performance materials. Furthermore, the high level of automation in modern tube mills reduces the need for manual labor, ensuring that production runs smoothly and efficiently, while minimizing human error. The tube mill machine is an integral part of modern manufacturing, capable of producing large volumes of high-quality tubes and pipes with minimal waste, making it a crucial tool for industries that rely on dependable and cost-effective tubing solutions.

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!