-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Forming and Sizing section

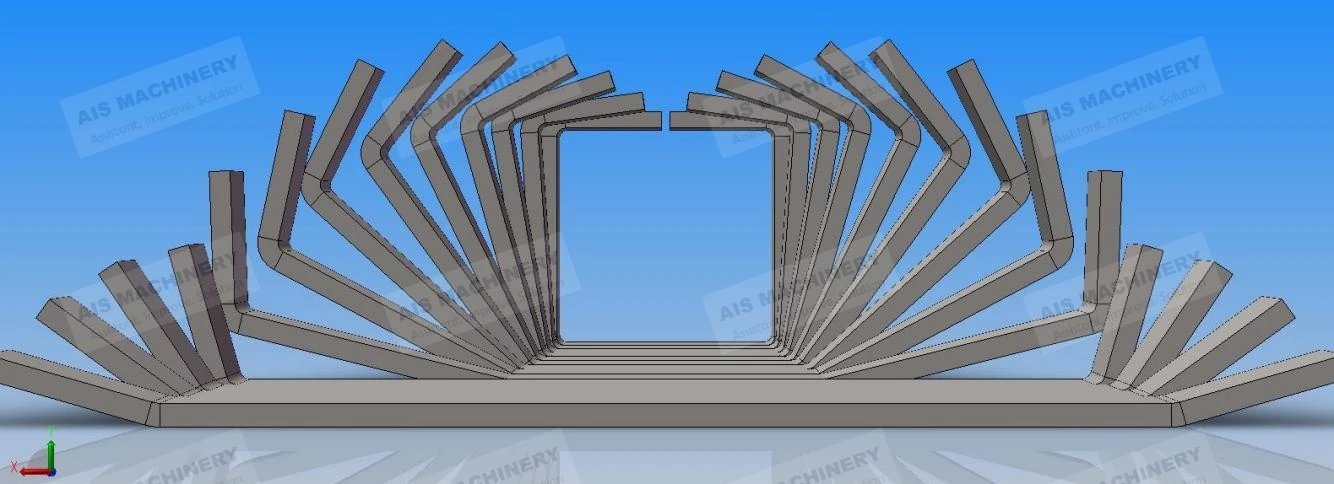

The forming and sizing section is a critical core process in ERW pipe equipment, directly determining the geometric shape and dimensional accuracy of the finished pipes. This section consists of multiple sets of frames and specialized forming dies that progressively shape the steel strip into the desired round or shaped pipe profile through multiple rolling passes.

During forming, the rollers on each frame apply uniform forming forces to the strip, smoothly bending and conforming it to the contour of the dies, ensuring precise cross-sectional profiles and smooth surface finishes. The forming and sizing system accurately controls pipe diameter, ovality, and wall thickness uniformity to meet various specifications and technical requirements.

Additionally, the forming and sizing section controls the position of the high-frequency weld seam, ensuring it is placed in an optimal stress location and aesthetically aligned, thereby enhancing weld strength and overall pipe performance. Through close coordination with the welding system, the forming and sizing equipment enables continuous, stable, and efficient pipe production.

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!