Cold roll forming equipment is to extrude steel strips or steel plates through rollers into different shapes, suitable for different needs. Common products include C-shaped profile, U-shaped profile, high-speed guardrails, color steel roofs, shelves and other uses.

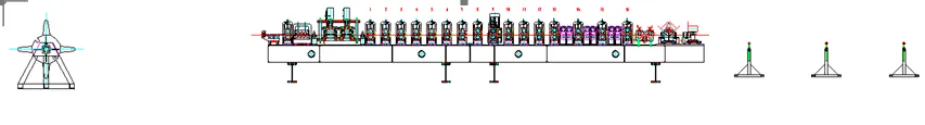

C/Z Purlin Cold Roll Forming Machine for Hat Profile continuously forming a steel profile. operations such as punching, stamping, can be done online.Then, the metal section is cut at the end of the line to the desired length.

Cold roll forming machine consists of gradually and continuously forming a steel profile.The method consists initially unrolling the strip of a steel coil, whose width corresponds to the developed of the finished profile.Steel strip engaged flat in a succession of several rollers whose shapes and numbers are variable depending on steel profile.Each operation corresponds to a profiling stand. Each stand with two horizontal shafts, one upper and the other lower, supporting the rollers with profiles, machined to match the forming perform and passes the metal strip.These rollers are made of D2, D3 material.

This strip in the profiling stands progressively transforms towards its final shape.This process respects the mechanical and characteristic stresses of the metal and allows the use of multiple grades of steels.Two horizontal shafts of each head are controlled by the motor of the machine, which ensures a regular drive of the strip.During the cold roll forming, operations such as punching holes, stamping logo, can be done online.

Then, the final metal section is cut by hydraulic servo cutoff machine to the desired length.

1.What is a roll forming machine used for?

Cold roll forming machines are used in a variety of industries, including construction, automotive, aerospace, and manufacturing. They are highly automated and can produce high-quality products at a high rate of speed, making them a popular choice for mass production.

2. BASIC DESIGN DATA

15 stands cold forming machine

|

Stands

|

15

|

|

Thikness range

|

Max 4.0mm

|

|

Shaft diameter

|

110mm

|

|

Forming speed

|

Max 30m/min,

|

|

Roller material

|

D3

|

|

Gear box

|

Casting of ductile iron shell material, 12M spiral bevel gear

|

|

Motor

|

one set

|

4. The technical flow of the production line

{Steel Tape}→ Uncoiler →Strip-head Cutter and welder→Spiral accumulator→Forming section →Hole punching device→Hydraulic servo driven cutoff→→ Run-out table

RELATION EQUIPMENT

We provides all equipment to tube mill entry section:

Coil Car

Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

Peeler and hold down roll arm

Flattening Machine

Automatic and Semi Auto Shearer & Butt Welder

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

TUBE MILL FINISHING SECTION

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

9. Drilling machine

SPARE PARTS TO CHOOSE

Our Spare Parts Apply:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

OUR CERTIFICATE

OUR SERVICE

Why Choose Us?

Leading Technology, Reliable Quality, Excellent Service!

Optimized Design, High quality material select!

Heat treatment process guarantee!

Spiral bevel gear, drum gear coupling and carburization.

Gear teeth quenching.

Driven system stable, efficient and wearable with lower noise.

High precision wear resisting and Long life of rollers.

All the machine Lathes, Key Grooves are positioned and Milled by CNC.

Our Service

Pre-sale service

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

After-sales service

1.We will delivery the machine and provide the documents on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions, Our fast and professional aftersales service engineer team will go to your factory to install the machine, give you the operating manual, And train your employee until they can operate the machine well.

3.We provide one year warranty and life-long technical support.

4.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

5 .24 hours for engineer response.

6.Your business relationship with us will be confidential to any third party.

Quality Control

We have the single quality department, that make sure the material of the raw materials is good, and ensure the machine running smoothly.

Tel:86-15176910262

Tel:86-15176910262