Ferrite rods are usually made of ferrite materials, and common types include manganese-zinc ferrite (MnZn) . This type of material has a high magnetic permeability and electrical properties suitable for high-frequency environments. It can work stably in the frequency range of 200kHz to 500kHz, and adapt to the high-speed operation requirements of welding pipe equipment.

During the high-frequency induction heating process, the Ferrite rod can effectively guide the current to flow along the edge of the pipe wall and concentrate the energy on the part to be welded. By enhancing the skin effect and proximity effect, the Ferrite rod promotes the rapid heating of the weld area, achieves full melting of the edge, and ensures the welding strength and forming quality. At the same time, it can also prevent the induced current from diffusing in the pipe, reduce energy loss, and improve overall energy efficiency.

Selecting a Ferrite rod with stable performance and matching material is of great significance for improving the thermal efficiency of the welding process, controlling the quality of the weld, and extending the life of the equipment. Its parameter design needs to be customized according to the pipe specifications, welding speed and frequency requirements to achieve the best use effect.

Impeder Cooling

All of our impeders are designed to ensure effective cooling and protection of the ferrite core inside the impeder. It is essential that ferrite is cooled efficiently to maximise the welding efficiency and maintain stable parameters for product quality.

1. What is Ferrite Impeder Rods

The Impeder is constructed of Ferrite material and is an essential accessory for use in high frequency welding of tubes and pipes. This material best meets the demanding requirements of high frequency welding. The Impeder lowers the reluctance of the magnetic path, thereby saving energy and improving overall process efficiency.Cores provide an ideal magnetic path even at high temperatures. High saturation flux combined with high resistance reducing eddy current losses improves mill efficiency. It's high density construction adds the mechanical strength for long life in the severe operating environment in a steel tube mill.

Coolant should be clean, preferably filtered. A pressure will ensure adequate cooling under most operating conditions. Coolant flow requirements vary widely due to inlet temperature, weld power, frequency and weld area geometry. In high power density situations and at high ambient temperatures, a small chiller for impeder and work coil coolant can greatly improve efficiency.

A high material permeability to ensure optimum flux concentration.

A high saturation induction at the working temperature which determines the maximum field in which the ferrite can usefully perform.

Ferrite impedance cores from Chinese manufacturers can help you achieve better and more efficient welding.

RELATION EQUIPMENT

We provides all equipment to tube mill entry section:

Coil Car

Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

Peeler and hold down roll arm

Flattening Machine

Automatic and Semi Auto Shearer & Butt Welder

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

TUBE MILL FINISHING SECTION

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

9. Drilling machine

SPARE PARTS TO CHOOSE

Our Spare Parts Apply:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

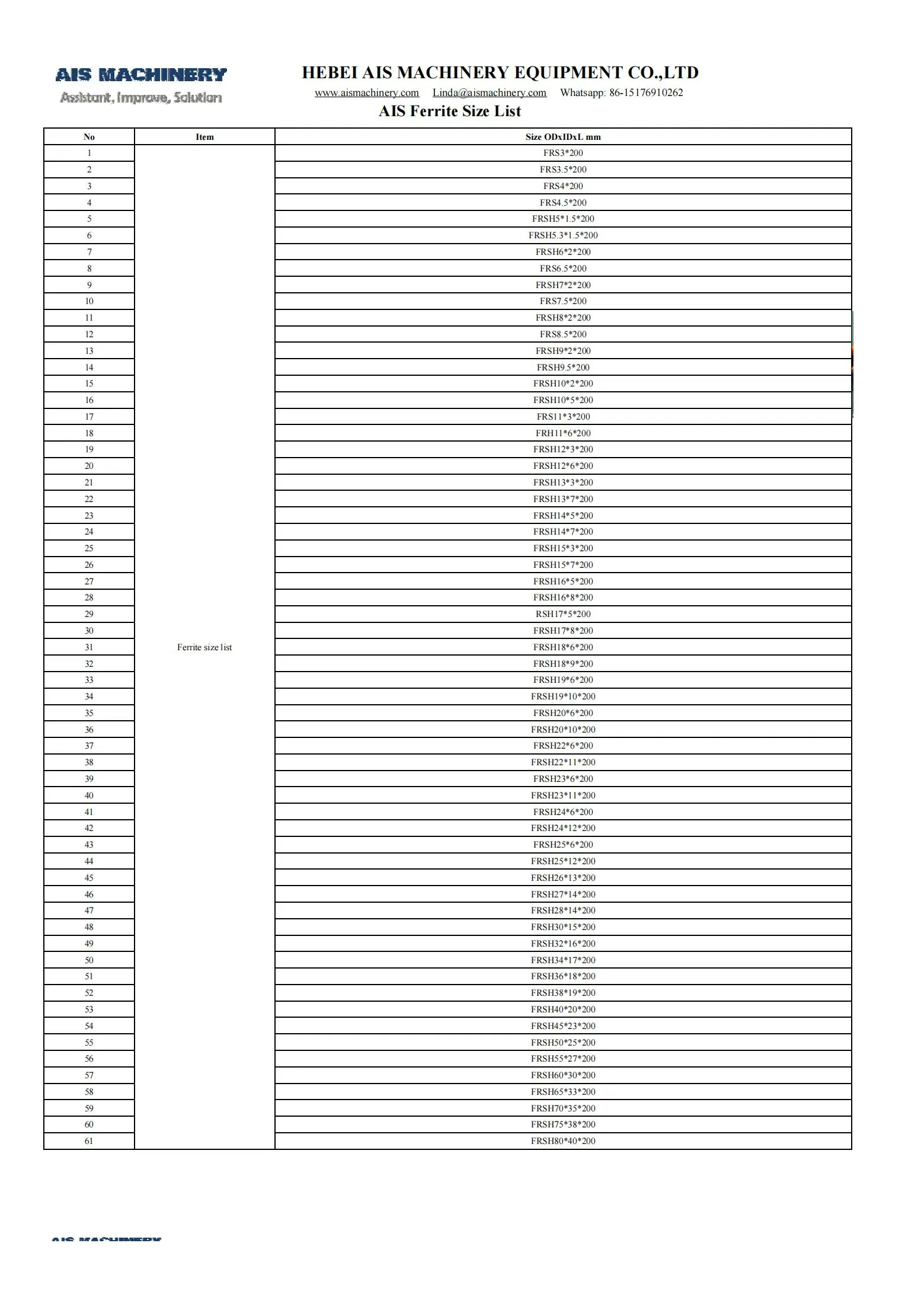

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

OUR CERTIFICATE

OUR SERVICE

Why Choose Us?

Leading Technology, Reliable Quality, Excellent Service!

Optimized Design, High quality material select!

Heat treatment process guarantee!

Spiral bevel gear, drum gear coupling and carburization.

Gear teeth quenching.

Driven system stable, efficient and wearable with lower noise.

High precision wear resisting and Long life of rollers.

All the machine Lathes, Key Grooves are positioned and Milled by CNC.

Our Service

Pre-sale service

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

After-sales service

1.We will delivery the machine and provide the documents on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions, Our fast and professional aftersales service engineer team will go to your factory to install the machine, give you the operating manual, And train your employee until they can operate the machine well.

3.We provide one year warranty and life-long technical support.

4.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

5 .24 hours for engineer response.

6.Your business relationship with us will be confidential to any third party.

Quality Control

We have the single quality department, that make sure the material of the raw materials is good, and ensure the machine running smoothly.

Tel:86-15176910262

Tel:86-15176910262