Ferrite rods are usually made of ferrite materials, and common types include manganese-zinc ferrite (MnZn) . This type of material has a high magnetic permeability and electrical properties suitable for high-frequency environments. It can work stably in the frequency range of 200kHz to 500kHz, and adapt to the high-speed operation requirements of welding pipe equipment.

During the high-frequency induction heating process, the Ferrite rod can effectively guide the current to flow along the edge of the pipe wall and concentrate the energy on the part to be welded. By enhancing the skin effect and proximity effect, the Ferrite rod promotes the rapid heating of the weld area, achieves full melting of the edge, and ensures the welding strength and forming quality. At the same time, it can also prevent the induced current from diffusing in the pipe, reduce energy loss, and improve overall energy efficiency.

Selecting a Ferrite rod with stable performance and matching material is of great significance for improving the thermal efficiency of the welding process, controlling the quality of the weld, and extending the life of the equipment. Its parameter design needs to be customized according to the pipe specifications, welding speed and frequency requirements to achieve the best use effect.

Impeder Cooling

Omnes nostri impediti ordinantur ad efficacem refrigerationem et tutelam nuclei ferriti intus impedientis. Necessarium est quod ferrite refrigeratur efficaciter ad efficientiam glutino augendam et ad parametri producti qualitatem stabiliendam conservandam.

1. Ferrite Quid rods Impeder?

Impeder ex materia Ferri construitur et accessoria essentialis ad usum frequentiae fistularum et tibiarum alta est. Haec materia maxime occurrit exigentibus postulatis altae frequentiae glutino. Impeder reluctantia demittit iter magneticae, ita industriam salvificam et altiore processu augendo efficientiam. Cores praebet semitam magneticam idealem etiam in calidis temperaturis. Alta satietatem fluxum cum magno resistentia reducendo torsit currenti damna efficaciam molendini meliorem facit. Princeps densitatis constructionis vim mechanicam addit ad vitam longam in gravi ambitu operante in tubo ferreo molendini.

Coolant mundum esse, potius percolantur. Pressio sufficientem refrigerationem sub condicionibus operantibus curabit. Coolantia fluunt requisita, late ob distantiam temperaturae, pactionem potentiae, frequentiae et in geometriae areae pactionem variant. In magna potentia densitatis adiunctis et in magnis temperaturis ambientibus, parva frigidior ob impedimentum et opus coilum coolant multum efficientiam emendare potest.

Magna materia permeability ut optimum fluxum conducit.

Magna satietatem inductio ad temperaturam laborantem qui agrum maximum determinat, in quo ferritus utiliter praestare potest.

Impedimentum ferrite nuclei e artifices Sinenses iuvare possunt ut melius et efficacius glutino consequantur.

COGNATIO ORNATUS

Nos omnem apparatum praebet ad sectionem molendini tubi viscus:

Coil Car

Singula et duplicata capita Un-coiler & hydraulica et pneumatica Un-coiler

Peeler et tenere in volumine arm

Machina adulatione

Automatic et Semi Auto Shearer & Butt Welder

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

TUBE MOLENDUM CONSUMMATIO SECTIO PRIMA

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

9. Drilling machine

PARCE partes eligere

Nostris parce partes applicare:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

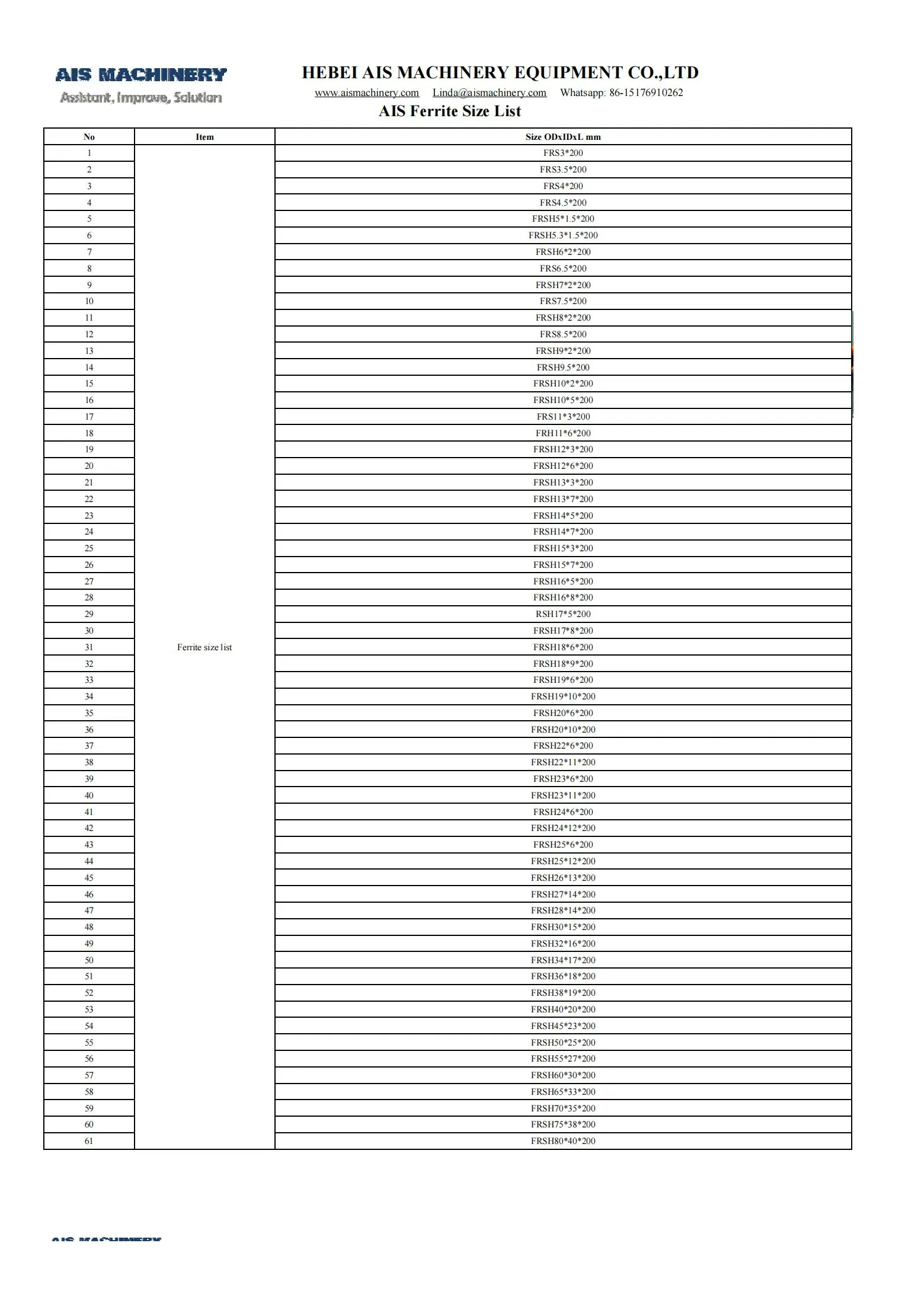

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

Testimonium nostrum

OPERA NOSTRA

Quid nos elige?

Ducens Technology, Reliable Quality, Excellent Service!

Optimized Design, High quality material select!

Caloris curatio processus spondet!

Calces cochleae revellere, orum calces copulatio et carburization.

Dentium calces exstingui.

Ratio acti stabilis, efficax et infatigabilis cum sonitu inferiori.

Summa subtilitate gerunt resistendo et longam tribulis vitam.

Tota machina Lathes, sulci Clavis a CNC cincta et molita sunt.

Our Service

Pre-venditionis officium

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

Post-Sales ministerium

1. Nos machinam trademus et documenta in tempore praebebunt ut machinam celeriter efficere possis

2. Praeparatio condiciones cum consummaveris, Ieiunium et professio nostra postsales servitii fectum ibit ad officinam tuam ut machinam instituat, manualem operantem tibi tribuat, et operarium tuum exerceat donec machinam bene operari possint.

3. Nos unum annum warantum et diuturnum technicum subsidium praebent.

4.Bene peritus & peritus baculus respondeat omnibus tuis quaestionibus Anglice et Sinice

5 .24 horae ad fectum responsum.

6. Negotium tuum cum nobis communicatio alicui tertiae parti secretior erit.

Qualitas Imperium

Unicum qualitatem habemus, quae materiam rudium materiarum bonam fac, et machinam nonumyter curet.

Tel:86-15176910262

Tel:86-15176910262