Warehouse Storage Rack Roll Forming Machine

1. Introduction

The Warehouse Pallet Rack Roll Forming Machine is designed for the high-efficiency production of upright frames, step beams, and horizontal braces used in industrial shelving and storage systems. It is suitable for mass production of roll-formed components with consistent dimensions, high strength, and minimal material waste.

2. Technical Specifications

| Item |

Specification |

| Raw Material |

Cold-rolled steel / Galvanized steel |

| Material Thickness |

1.5–2.5 mm (customizable) |

| Material Width |

100–500 mm (based on profile) |

| Forming Stations |

16–28 stations (depending on profile) |

| Forming Speed |

10–15 m/min (with punching) |

| Roller Material |

GCr15 steel, heat treated, chromed |

| Drive System |

Gearbox drive / Chain drive |

| Cutting Type |

Servo driven following cutoff |

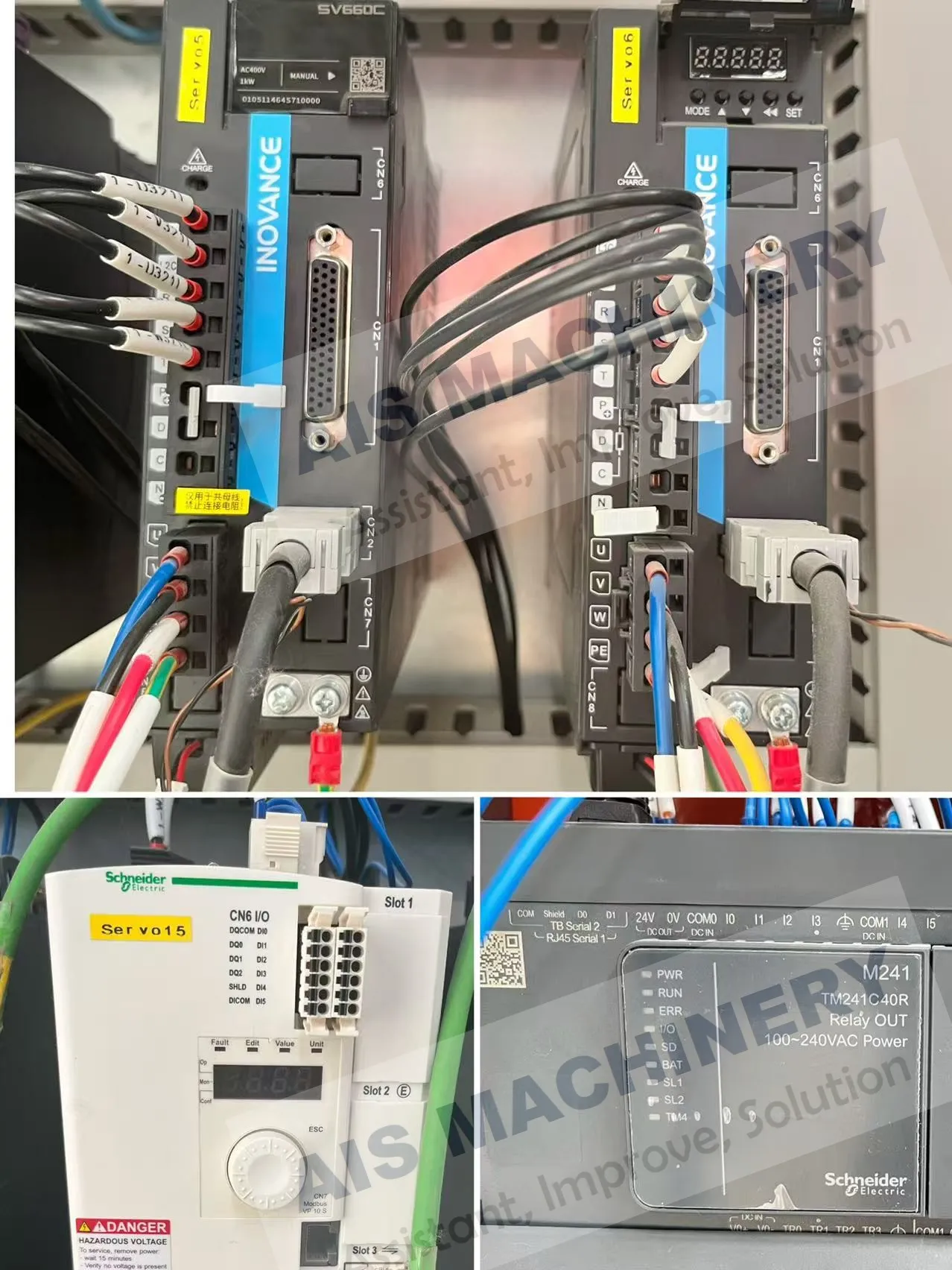

| PLC Control |

Siemens /China brand |

| Voltage |

380V / 50Hz / 3 Phase (customizable) |

\

\

3. Machine Composition

-

Uncoiler – Manual or hydraulic type, holds coil steel

-

Feeding & Leveling Unit – Ensures smooth, aligned feeding

-

Servo Punching Unit – Customized punching dies for beam holes or upright slots

-

Roll Forming System – Precision rollers for forming beam/upright shape

-

Cutting Unit – Hydraulic or flying shear, length-controlled

-

Output Table – Collects finished products

-

Control Cabinet (PLC) – Full automation, touch screen interface

-

Optional Devices: Pre-punching, notching, embossing, stacking systems

4. Application Scenarios

-

Industrial warehouse storage systems

-

Supermarket shelving

-

Cold storage rack systems

-

Logistic centers

-

Heavy-duty pallet racking

5. Production Flow

6. Operation Instructions

-

Load the steel coil on the uncoiler.

-

Adjust the leveling rollers to match thickness.

-

Load the required punching die (if needed).

-

Select product type and set parameters on PLC.

-

Run dry test (no material) to ensure alignment.

-

Feed steel into rollers and start production.

-

Monitor the forming and cutting accuracy during the run.

-

After production, clean and lubricate the rollers.

7. FAQs

Q1: Can it produce both uprights and beams on one line?

A1: Normally not; separate roller sets or machines are used for different profiles, but modular roller replacement systems are available.

Q2: How long does it take to change a profile?

A2: With manual roller change: 3–5 hours. With quick-change cassette system: under 1 hour.

Q3: What kind of punching is supported?

A3: Both inline servo punching and hydraulic punching are supported, depending on production requirements.

Q4: How accurate is the cutting length?

A4: ±1.0 mm with PLC length control and encoder system.

Q5: Is remote support available?

A5: Yes, the PLC supports remote troubleshooting via internet (if equipped).

8. Maintenance Tips

-

Regularly clean rollers and apply anti-rust oil

-

Check hydraulic oil level and filters monthly

-

Tighten all bolts and drive chains weekly

-

Inspect electric control cabinet for overheating

8. Safety Instructions

-

Never place hands near the roll station during operation.

-

Always disconnect power before adjusting tooling.

-

Emergency stops are located at the entry and exit ends.

-

Wear gloves and safety glasses when changing dies.

Haec habena in profiling progressive mutat ad ultimam figuram. Hic processus observantias mechanicas et notas passiones metalli et usum multiplicium graduum de steels. Duae sagittae horizontales uniuscuiusque capitis reguntur a motore machinae, quae efficit regularem clavum expoliationis. Durante frigore volvi formando, operationes ut foramina pulsandi, logo stampa, fieri potest online.

Deinde sectio metalli finalis ab servo hydraulico abscissionis machinae ad optatam longitudinem secatur.

1. Quid est tortamque machina usus est?

Frigidum volumen machinarum formantium in variis industriis adhibentur, inclusis constructionibus, autocinetis, aerospace, et fabricandis. Magnopere automati sunt et producere possunt productos summus qualitas celeritatis magnae, eos popularem electionem efficiendi ad massam producendi.

COGNATIO ORNATUS

Nos omnem apparatum praebet ad sectionem molendini tubi viscus:

Coil Car

Singula et duplicata capita Un-coiler & hydraulica et pneumatica Un-coiler

Peeler et tenere in volumine arm

Machina adulatione

Automatic et Semi Auto Shearer & Butt Welder

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

TUBE MOLENDUM CONSUMMATIO SECTIO PRIMA

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

9. Drilling machine

PARCE partes eligere

Nostris parce partes applicare:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

Testimonium nostrum

OPERA NOSTRA

Quid nos elige?

Ducens Technology, Reliable Quality, Excellent Service!

Optimized Design, High quality material select!

Caloris curatio processus spondet!

Calces cochleae revellere, orum calces copulatio et carburization.

Dentium calces exstingui.

Ratio acti stabilis, efficax et infatigabilis cum sonitu inferiori.

Summa subtilitate gerunt resistendo et longam tribulis vitam.

Tota machina Lathes, sulci Clavis a CNC cincta et molita sunt.

Our Service

Pre-venditionis officium

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

Post-Sales ministerium

1. Nos machinam trademus et documenta in tempore praebebunt ut machinam celeriter efficere possis

2. Praeparatio condiciones cum consummaveris, Ieiunium et professio nostra postsales servitii fectum ibit ad officinam tuam ut machinam instituat, manualem operantem tibi tribuat, et operarium tuum exerceat donec machinam bene operari possint.

3. Nos unum annum warantum et diuturnum technicum subsidium praebent.

4.Bene peritus & peritus baculus respondeat omnibus tuis quaestionibus Anglice et Sinice

5 .24 horae ad fectum responsum.

6. Negotium tuum cum nobis communicatio alicui tertiae parti secretior erit.

Qualitas Imperium

Unicum qualitatem habemus, quae materiam rudium materiarum bonam fac, et machinam nonumyter curet.

Tel:86-15176910262

Tel:86-15176910262