Warehouse Storage Rack Roll Forming Machine

1. Introduction

The Warehouse Pallet Rack Roll Forming Machine is designed for the high-efficiency production of upright frames, step beams, and horizontal braces used in industrial shelving and storage systems. It is suitable for mass production of roll-formed components with consistent dimensions, high strength, and minimal material waste.

2. Technical Specifications

| Item |

Specification |

| Raw Material |

Cold-rolled steel / Galvanized steel |

| Material Thickness |

1.5–2.5 mm (customizable) |

| Material Width |

100–500 mm (based on profile) |

| Forming Stations |

16–28 stations (depending on profile) |

| Forming Speed |

10–15 m/min (with punching) |

| Roller Material |

GCr15 steel, heat treated, chromed |

| Drive System |

Gearbox drive / Chain drive |

| Cutting Type |

Servo driven following cutoff |

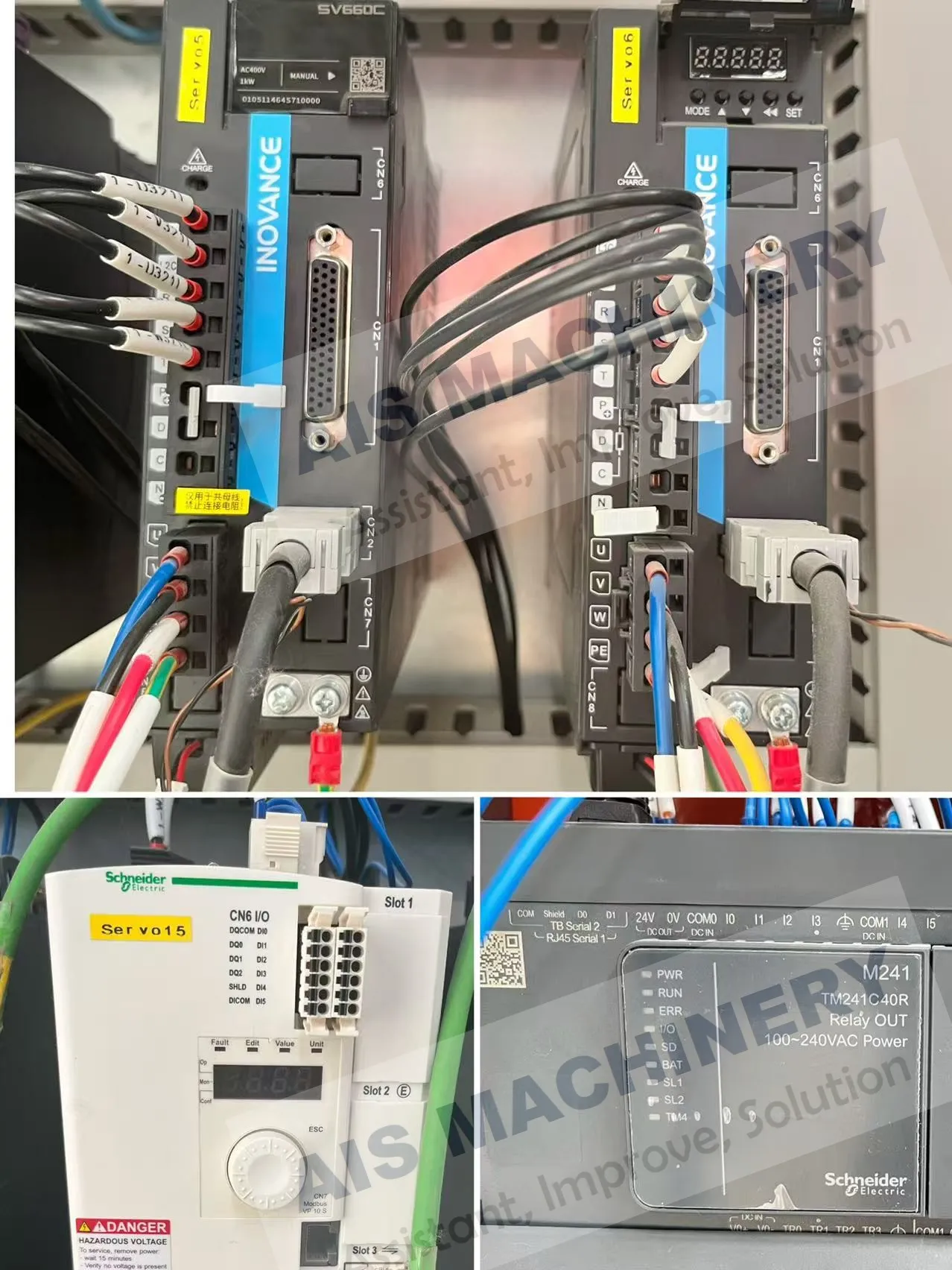

| PLC Control |

Siemens /China brand |

| Voltage |

380V / 50Hz / 3 Phase (customizable) |

\

\

3. Machine Composition

-

Uncoiler – Manual or hydraulic type, holds coil steel

-

Feeding & Leveling Unit – Ensures smooth, aligned feeding

-

Servo Punching Unit – Customized punching dies for beam holes or upright slots

-

Roll Forming System – Precision rollers for forming beam/upright shape

-

Cutting Unit – Hydraulic or flying shear, length-controlled

-

Output Table – Collects finished products

-

Control Cabinet (PLC) – Full automation, touch screen interface

-

Optional Devices: Pre-punching, notching, embossing, stacking systems

4. Application Scenarios

-

Industrial warehouse storage systems

-

Supermarket shelving

-

Cold storage rack systems

-

Logistic centers

-

Heavy-duty pallet racking

5. Production Flow

6. Operation Instructions

-

Load the steel coil on the uncoiler.

-

Adjust the leveling rollers to match thickness.

-

Load the required punching die (if needed).

-

Select product type and set parameters on PLC.

-

Run dry test (no material) to ensure alignment.

-

Feed steel into rollers and start production.

-

Monitor the forming and cutting accuracy during the run.

-

After production, clean and lubricate the rollers.

7. FAQs

Q1: Can it produce both uprights and beams on one line?

A1: Normally not; separate roller sets or machines are used for different profiles, but modular roller replacement systems are available.

Q2: How long does it take to change a profile?

A2: With manual roller change: 3–5 hours. With quick-change cassette system: under 1 hour.

Q3: What kind of punching is supported?

A3: Both inline servo punching and hydraulic punching are supported, depending on production requirements.

Q4: How accurate is the cutting length?

A4: ±1.0 mm with PLC length control and encoder system.

Q5: Is remote support available?

A5: Yes, the PLC supports remote troubleshooting via internet (if equipped).

8. Maintenance Tips

-

Regularly clean rollers and apply anti-rust oil

-

Check hydraulic oil level and filters monthly

-

Tighten all bolts and drive chains weekly

-

Inspect electric control cabinet for overheating

8. Safety Instructions

-

Never place hands near the roll station during operation.

-

Always disconnect power before adjusting tooling.

-

Emergency stops are located at the entry and exit ends.

-

Wear gloves and safety glasses when changing dies.

Strip pada profil ini secara bertahap berubah menuju bentuk akhirnya. Proses ini mematuhi tekanan mekanis dan karakteristik logam serta memungkinkan penggunaan berbagai tingkatan baja. Dua poros horizontal pada setiap kepala dikontrol oleh motor mesin, yang memastikan penggerak strip secara teratur. Selama proses pembentukan gulungan dingin, operasi seperti melubangi, mencap logo, dapat dilakukan secara daring.

Kemudian, bagian logam akhir dipotong oleh mesin pemotong servo hidrolik sesuai panjang yang diinginkan.

1.Apa kegunaan mesin roll forming?

Mesin cold roll forming digunakan dalam berbagai industri, termasuk konstruksi, otomotif, kedirgantaraan, dan manufaktur. Mesin ini sangat otomatis dan dapat menghasilkan produk berkualitas tinggi dengan kecepatan tinggi, sehingga menjadi pilihan populer untuk produksi massal.

PERALATAN HUBUNGAN

Kami menyediakan semua peralatan untuk bagian masuk pabrik tabung:

Mobil Koil

Pembuka Kepala Tunggal dan Ganda, Pembuka Kepala Hidrolik dan Pneumatik

Pengupas dan tahan lengan gulung

Mesin Perata

Mesin Pemotong dan Las Ujung Otomatis dan Semi Otomatis

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

BAGIAN FINISHING TUBE MILL

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

9. Drilling machine

SUKU CADANG UNTUK DIPILIH

Suku Cadang Kami Berlaku:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

SERTIFIKAT KAMI

LAYANAN KAMI

Mengapa Memilih Kami?

Teknologi Terkemuka, Kualitas Andal, Layanan Luar Biasa!

Desain yang dioptimalkan, Pilihan material berkualitas tinggi!

Jaminan proses perlakuan panas!

Roda gigi spiral bevel, kopling roda gigi drum dan karburisasi.

Pendinginan gigi roda gigi.

Sistem penggerak stabil, efisien, dan dapat dipakai dengan tingkat kebisingan lebih rendah.

Ketahanan aus dengan presisi tinggi dan umur rol yang panjang.

Semua mesin Bubut, Alur Kunci diposisikan dan digiling oleh CNC.

Layanan Kami

Layanan pra-penjualan

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

Layanan purna jual

1. Kami akan mengirimkan mesin dan memberikan dokumen tepat waktu untuk memastikan Anda bisa mendapatkan mesin dengan cepat

2. Setelah Anda menyelesaikan kondisi Persiapan, tim teknisi layanan purna jual kami yang cepat dan profesional akan pergi ke pabrik Anda untuk memasang mesin, memberi Anda manual pengoperasian, dan melatih karyawan Anda hingga mereka dapat mengoperasikan mesin dengan baik.

3. Kami menyediakan garansi satu tahun dan dukungan teknis seumur hidup.

4. Staf yang terlatih & berpengalaman akan menjawab semua pertanyaan Anda dalam bahasa Inggris dan Mandarin

5,24 jam untuk respon teknisi.

6.Hubungan bisnis Anda dengan kami akan dirahasiakan dari pihak ketiga mana pun.

Kontrol Kualitas

Kami memiliki departemen kualitas tunggal, yang memastikan bahan bakunya bagus, dan memastikan mesin berjalan lancar.

Telp:86-15176910262

Telp:86-15176910262