Warehouse Storage Rack Roll Forming Machine

1. Introduction

The Warehouse Pallet Rack Roll Forming Machine is designed for the high-efficiency production of upright frames, step beams, and horizontal braces used in industrial shelving and storage systems. It is suitable for mass production of roll-formed components with consistent dimensions, high strength, and minimal material waste.

2. Technical Specifications

| Item |

Specification |

| Raw Material |

Cold-rolled steel / Galvanized steel |

| Material Thickness |

1.5–2.5 mm (customizable) |

| Material Width |

100–500 mm (based on profile) |

| Forming Stations |

16–28 stations (depending on profile) |

| Forming Speed |

10–15 m/min (with punching) |

| Roller Material |

GCr15 steel, heat treated, chromed |

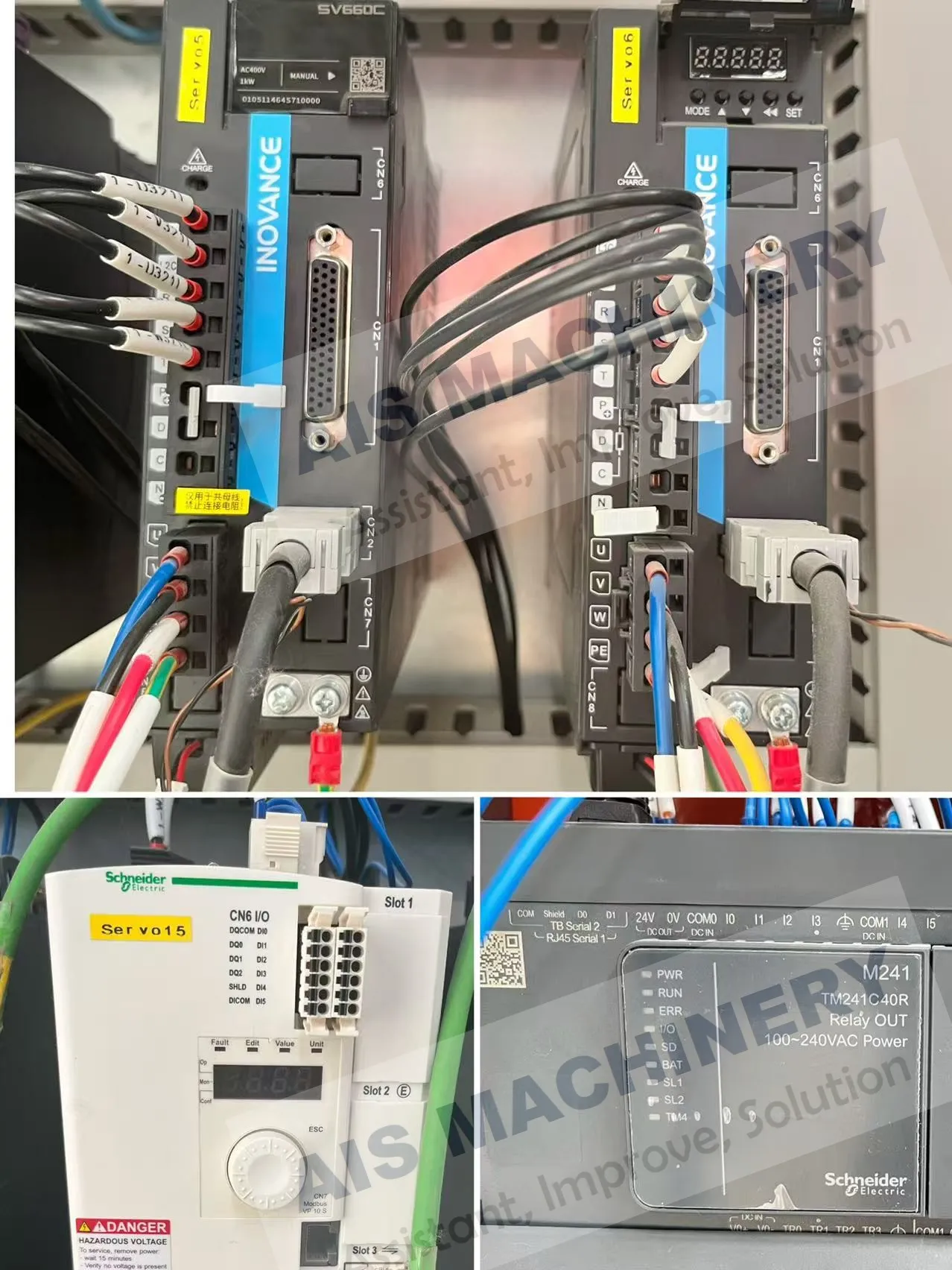

| Drive System |

Gearbox drive / Chain drive |

| Cutting Type |

Servo driven following cutoff |

| PLC Control |

Siemens /China brand |

| Voltage |

380V / 50Hz / 3 Phase (customizable) |

\

\

3. Machine Composition

-

Uncoiler – Manual or hydraulic type, holds coil steel

-

Feeding & Leveling Unit – Ensures smooth, aligned feeding

-

Servo Punching Unit – Customized punching dies for beam holes or upright slots

-

Roll Forming System – Precision rollers for forming beam/upright shape

-

Cutting Unit – Hydraulic or flying shear, length-controlled

-

Output Table – Collects finished products

-

Control Cabinet (PLC) – Full automation, touch screen interface

-

Optional Devices: Pre-punching, notching, embossing, stacking systems

4. Application Scenarios

-

Industrial warehouse storage systems

-

Supermarket shelving

-

Cold storage rack systems

-

Logistic centers

-

Heavy-duty pallet racking

5. Production Flow

6. Operation Instructions

-

Load the steel coil on the uncoiler.

-

Adjust the leveling rollers to match thickness.

-

Load the required punching die (if needed).

-

Select product type and set parameters on PLC.

-

Run dry test (no material) to ensure alignment.

-

Feed steel into rollers and start production.

-

Monitor the forming and cutting accuracy during the run.

-

After production, clean and lubricate the rollers.

7. FAQs

Q1: Can it produce both uprights and beams on one line?

A1: Normally not; separate roller sets or machines are used for different profiles, but modular roller replacement systems are available.

Q2: How long does it take to change a profile?

A2: With manual roller change: 3–5 hours. With quick-change cassette system: under 1 hour.

Q3: What kind of punching is supported?

A3: Both inline servo punching and hydraulic punching are supported, depending on production requirements.

Q4: How accurate is the cutting length?

A4: ±1.0 mm with PLC length control and encoder system.

Q5: Is remote support available?

A5: Yes, the PLC supports remote troubleshooting via internet (if equipped).

8. Maintenance Tips

-

Regularly clean rollers and apply anti-rust oil

-

Check hydraulic oil level and filters monthly

-

Tighten all bolts and drive chains weekly

-

Inspect electric control cabinet for overheating

8. Safety Instructions

-

Never place hands near the roll station during operation.

-

Always disconnect power before adjusting tooling.

-

Emergency stops are located at the entry and exit ends.

-

Wear gloves and safety glasses when changing dies.

Esta banda en los puestos de perfilado se transforma progresivamente hacia su forma final. Este proceso respeta las tensiones mecánicas y características del metal y permite el uso de múltiples calidades de aceros. Dos ejes horizontales de cada cabezal son controlados por el motor de la máquina, lo que garantiza un arrastre regular de la banda. Durante el conformado en frío, operaciones como punzonado, estampación de logotipos, se pueden realizar en línea.

Luego, la sección de metal final se corta mediante una máquina de corte servo hidráulica a la longitud deseada.

1.¿Para qué se utiliza una máquina perfiladora?

Las máquinas perfiladoras en frío se utilizan en diversas industrias, como la construcción, la automoción, la aeroespacial y la fabricación. Están altamente automatizadas y pueden producir productos de alta calidad a gran velocidad, lo que las convierte en una opción popular para la producción en masa.

EQUIPO DE RELACIÓN

Proporcionamos todo el equipamiento para la sección de entrada del molino de tubos:

Carro de bobinas

Desenrollador de cabezal simple y doble y desenrollador hidráulico y neumático

Pelador y brazo de sujeción del rodillo

Maquina aplanadora

Cizalla y soldadora a tope automática y semiautomática

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

SECCIÓN DE ACABADO DE LAMINADORAS DE TUBOS

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

9. Drilling machine

REPUESTOS A ELEGIR

Nuestras piezas de repuesto se aplican:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

NUESTRO CERTIFICADO

NUESTRO SERVICIO

¿Por qué elegirnos?

¡Tecnología líder, calidad confiable, excelente servicio!

¡Diseño optimizado, selección de materiales de alta calidad!

¡Garantía de proceso de tratamiento térmico!

Engranajes cónicos espirales, acoplamiento de engranajes de tambor y carburación.

Temple de dientes de engranajes.

Sistema accionado estable, eficiente y portátil con menor ruido.

Rodillos resistentes al desgaste de alta precisión y de larga vida útil.

Todos los tornos y ranuradores de las máquinas están posicionados y fresados mediante CNC.

Nuestro servicio

Servicio de preventa

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

Servicio postventa

1. Entregaremos la máquina y proporcionaremos los documentos a tiempo para asegurarnos de que pueda obtener la máquina rápidamente.

2. Cuando termine las condiciones de preparación, nuestro equipo de ingenieros de servicio posventa rápido y profesional irá a su fábrica para instalar la máquina, le entregará el manual de funcionamiento y capacitará a sus empleados hasta que puedan operar bien la máquina.

3. Ofrecemos un año de garantía y soporte técnico de por vida.

4. Nuestro personal capacitado y experimentado responderá todas sus consultas en inglés y chino.

5,24 horas para la respuesta del ingeniero.

6. Su relación comercial con nosotros será confidencial para cualquier tercero.

Control de calidad

Contamos con un departamento de calidad único, que se asegura de que el material de las materias primas sea bueno y garantiza que la máquina funcione sin problemas.

Teléfono: 86-15176910262

Teléfono: 86-15176910262