The 10-inch ERW tube mill is designed for continuous and automated production of medium to large-diameter welded steel pipes. It transforms steel strips into round pipes through forming, high-frequency welding, sizing, and cutting processes. The equipment is highly efficient, reliable, and suitable for high-strength, high-precision steel pipe manufacturing.

Applicable pipe types include: structural pipes, fluid pipes, pressure pipes, pile pipes, and general-purpose steel tubes.

List of Equipment Supply

|

No.

|

Equipment Name

|

Description

|

|

1

|

Hydraulic Uncoiler Car

|

Transfers steel coils to the decoiler

|

|

2

|

Double-cone Hydraulic Decoiler

|

Automatically uncoils and holds coils (up to 15 tons)

|

|

3

|

Shear & Butt Welder

|

Joins the ends of two coils for continuous feeding

|

|

4

|

Accumulator (Horizontal)

|

Maintains tension and buffering during continuous operation

|

|

5

|

Forming Mill (Rough/Mid/Finishing)

|

Gradually bends the strip into round shape

|

|

6

|

High-Frequency Welding Unit

|

Solid-state or IGBT system with auto load matching

|

|

7

|

Inner/Outer Burr Removers

|

Trims internal and external weld seams for smooth pipe surface

|

|

8

|

Cooling Section

|

Adjustable water spray zones for weld and pipe body cooling

|

|

9

|

Sizing Mill

|

Ensures precise outer diameter and roundness of pipes

|

|

10

|

Flying Saw (Hot/Milling)

|

Servo-controlled cutting to length with anti-vibration mechanism

|

|

11

|

Output Conveyor & Stacker

|

Aligns, stacks, and prepares pipes for packaging

|

|

12

|

Electrical Control System

|

Centralized PLC+HMI interface, with real-time monitoring

|

|

13

|

Hydraulic & Lubrication Unit

|

Powers the system with automated oil pressure and temperature control

|

2. BASIC DESIGN DATA

El diseño de la línea propuesta se basa en la siguiente especificación:

Equipment Advantages

-

Stable Construction: Heavy-duty welded frame ensures long-term durability

-

Intelligent Control: Full PLC control with alarms, diagnostics, and remote support

-

Quick Changeover: Supports multiple profiles (round, square, rectangular)

-

Excellent Weld Quality: Precision-matched HF system ensures solid welds

-

Energy Efficient: Inverter-controlled drives reduce power consumption by over 20%

-

Modular Design: Optional upgrades for stackers, cutting units, inspection systems

Welding Principle

Using high-frequency induction heating, the strip edges are rapidly heated to a plastic state, then squeezed together by pressure rollers to form a continuous weld.

-

Advantages: Smooth weld seam, small heat-affected zone, no filler material needed

-

Key Parameters: HF power adjustment, coil alignment, squeeze pressure

-

Burr Removal: Optional internal and external scarfing improves final product finish

Operating Procedure

-

Ensure all systems (electric, hydraulic, water) are operational

-

Load coil → Shear & weld → Accumulate strip → Forming & welding → Cooling → Sizing → Cutting

-

Check roll wear, blade sharpness, and induction coil daily

-

Monitor welding temperature, strip tension, and sizing output via HMI

-

Shutdown sequence: stop line → cut power → close water/air systems in order

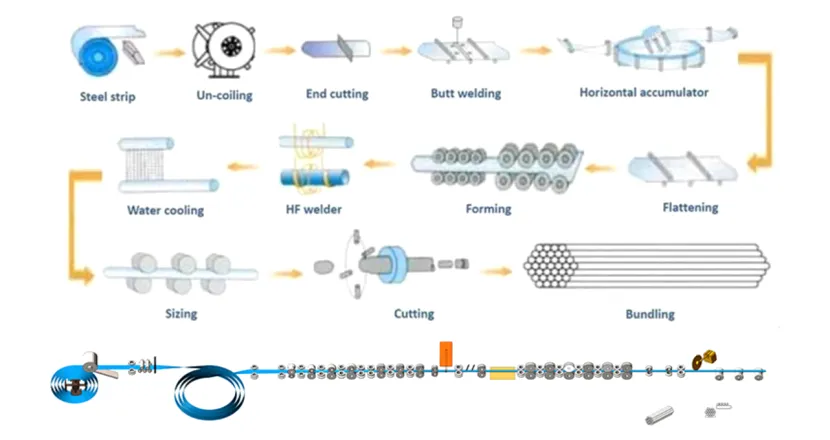

The Flow of the Production Line

{Steel Tape}→Coil car→ Uncoiler →Peeler and hold down roll→Flattener→ Strip-head Cutter and welder→Spiral accumulator→Forming section(Flattening unit +Main driving unit +Forming unit +Guide unit +squeeze roller)+ De-burr frame →→Cooling unit →→ Sizing unit and straightener →→Cutoff saw →→ Run-out table →→Straingtener machine →→Chamfer machine →→Hydro tester machine →→automatic package machine

Selection Advice for Customers

-

-

Define main product specs (e.g., Φ168, Φ219) when configuring forming stations

-

Wall thickness range determines required HF power and saw type

-

Export customers should specify voltage, control language, and certification needs (e.g., CE)

-

Optional upgrades: online seam inspection, laser OD measurement, automatic stacking systems

-

Teléfono: 86-15176910262

Teléfono: 86-15176910262