-

Teléfono: 86-15176910262

Teléfono: 86-15176910262

-

Buscar

Roll Forming Tube Mill

Jul . 16, 2025 10:13

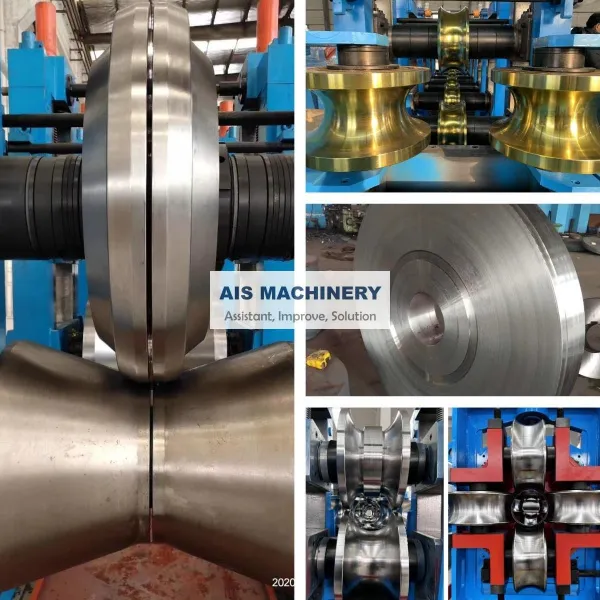

Modern metal fabrication demands precision and productivity, which is why our laminador de tubos formador de rollos technology leads the industry in pipe and tube production. As specialists in steel tubing mill equipment, we provide complete solutions from entry-level China roll forming machine configurations to fully automated fábrica de tubos systems. Our innovative roll forming tube processes deliver exceptional dimensional accuracy and surface quality while maximizing production output for round, square, and rectangular tubing applications.

Precision Pipe Mill Technology

Our fábrica de tubos systems feature precision-engineered forming rolls that gradually shape flat strip into perfect tubular profiles with tolerances to ±0.1mm. The heavy-duty construction of our laminador de tubos formador de rollos ensures stable operation when processing materials up to 12mm thick. Unlike conventional China roll forming machine options, our steel tubing mill incorporates laser guidance and automatic thickness monitoring for consistent quality control. Manufacturers particularly value our fábrica de tubos versatility - the same base machine can be quickly reconfigured for different tube diameters from 10mm to 300mm.

Complete Steel Tubing Mill Systems

For turnkey production solutions, our comprehensive steel tubing mill configurations include all essential components for efficient tube manufacturing. From uncoilers and strip accumulators to high-frequency welders and sizing stations, our laminador de tubos formador de rollos systems are designed for continuous operation. The advanced fábrica de tubos technology we employ can process material at speeds exceeding 120 meters per minute. Our steel tubing mill solutions often include integrated testing, cutting, and packaging stations to create finished product ready for shipment.

Innovative Roll Forming Tube Process

The roll forming tube technology we've perfected delivers unmatched profile accuracy and mechanical properties. Our laminador de tubos formador de rollos stands feature computer-optimized roll designs that ensure smooth material flow with minimal stress during forming. The precision-ground forming rolls in our China roll forming machine products maintain tight tolerances even at maximum production speeds. For high-volume applications, our fábrica de tubos systems can incorporate inline welding, sizing, and cutting to create complete turnkey solutions. The roll forming tube process produces tubing with superior concentricity compared to conventional pipe manufacturing methods.

Heavy-Duty China Roll Forming Machine Quality

While offering competitive China roll forming machine pricing, we maintain uncompromising quality standards in our laminador de tubos formador de rollos production. Our manufacturing facilities utilize CNC machining centers and coordinate measuring machines to ensure every component meets exact specifications. The robust construction of our fábrica de tubos equipment guarantees years of reliable service in demanding industrial environments. Many global manufacturers now source our China roll forming machine solutions for their exceptional value - combining European-level engineering with competitive pricing. All our steel tubing mill products undergo rigorous testing before shipment.

Custom Roll Forming Tube Mill Solutions

Understanding that each manufacturer has unique requirements, we specialize in customized laminador de tubos formador de rollos configurations. Our engineering team designs tailored fábrica de tubos solutions for specialized materials, unusual profiles, or specific production volumes. From compact China roll forming machine units for prototyping to massive steel tubing mill lines for OEMs, we provide equipment scaled precisely to your needs. The modular design of our roll forming tube systems allows for future upgrades as your production requirements evolve.

Roll Forming Tube Mill FAQs

What materials can your fábrica de tubos process?

Our fábrica de tubos handles carbon steel, stainless steel, aluminum, and various alloys from 0.3mm to 12mm thickness.

How does your roll forming tube process compare to extrusion?

Unlike extrusion, our roll forming tube process works at room temperature, preserves material properties, and offers greater flexibility for profile changes.

What production speeds can your steel tubing mill achieve?

Depending on material and profile complexity, our steel tubing mill typically operates at 20-120 meters per minute.

Can your China roll forming machine produce variable wall thickness tubes?

Yes, our advanced China roll forming machine models can process tailor-welded blanks for variable wall thickness applications.

What maintenance does your laminador de tubos formador de rollos require?

Our laminador de tubos formador de rollos designs emphasize reliability with automatic lubrication systems and easily accessible components.

From basic China roll forming machine units to complete steel tubing mill systems, our roll forming tube technology delivers precision, efficiency, and reliability. Contact our engineering team today to discuss your fábrica de tubos requirements.

Permeable

Permeable

This is the first article

Productos relacionados

Noticias relacionadas

High-Speed Roll Forming Tube Mill Precision Square & Round Tube Production

May . 07, 2025 15:39

Productos relacionados

Noticias relacionadas

Enviar un mensaje

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!