-

Teléfono: 86-15176910262

Teléfono: 86-15176910262

-

Buscar

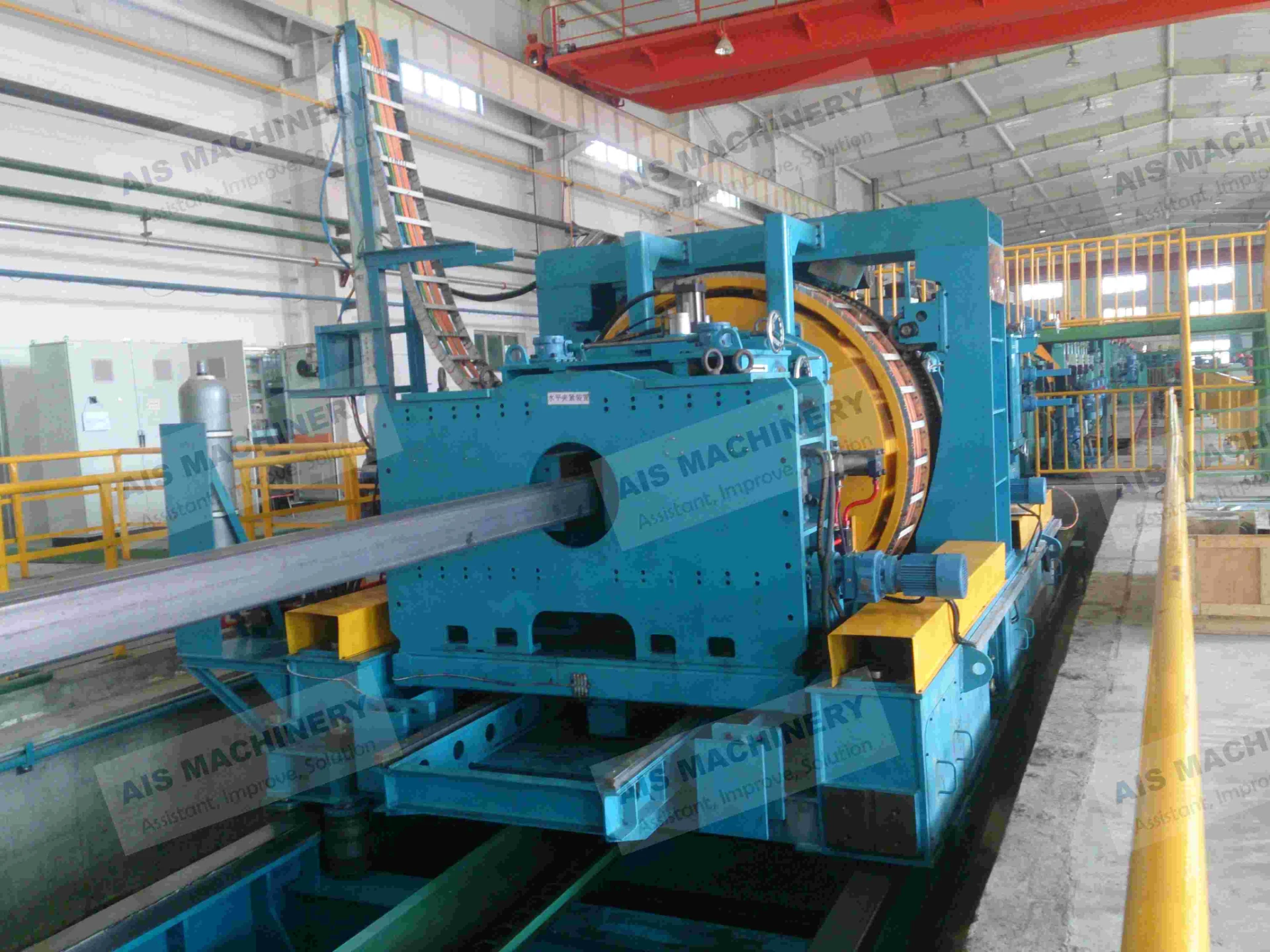

Molino de tubos FFX

FFX (Flexible Forming and Sizing) technology is one of the most popular forming solutions in the welding pipe industry today. Its core advantage lies in the "shared mold for the opening section," which allows for quick switching between different pipe diameters and cross-sectional specifications, significantly increasing equipment utilization and production flexibility. Whether for mass production or quick switching between small batches of different specifications, the FFX system offers high-efficiency, stable support.

How Does A FFX(Flexible Forming and Sizing Work?

Un laminador de tubos funciona transformando tiras o bobinas de acero planas en tubos de acero soldados mediante una serie de procesos mecánicos. El primer paso consiste en desenrollar y alimentar la tira de acero plana al laminador. A continuación, la tira se guía a través de una serie de rodillos que la moldean progresivamente hasta darle una forma cilíndrica. A medida que la tira pasa por estos rodillos, sus bordes se juntan y quedan listos para ser soldados. El siguiente paso clave del proceso es la soldadura. Los bordes del tubo se sueldan entre sí mediante tecnología de soldadura de alta frecuencia o láser, que utiliza calor para fusionar los bordes en una costura sólida y continua. Después de la soldadura, el tubo pasa por un conjunto de rodillos y unidades de enfriamiento para garantizar que mantenga su forma y se enfríe a una temperatura estable. Después del enfriamiento, el tubo se endereza para eliminar cualquier distorsión causada por los procesos de formación y soldadura.

El tubo pasa luego por varios pasos de acabado, como recortar los bordes, cortarlo en longitudes específicas y, en ocasiones, realizar un tratamiento térmico para mejorar sus propiedades mecánicas. El tubo también puede recubrirse o pulirse según la aplicación prevista. Durante todo este proceso, el laminador de tubos está equipado con sistemas de control para supervisar parámetros clave como la velocidad de avance, la tensión y las condiciones de soldadura, lo que garantiza una producción de tubos uniforme y precisa. El resultado es un tubo soldado duradero y de alta calidad que cumple con las especificaciones requeridas de resistencia, tamaño y acabado de la superficie. Los laminadores de tubos se utilizan en una variedad de industrias, incluidas la construcción, la automoción y la energía, para producir tubos para aplicaciones estructurales, de tuberías y otras.

Working Principle

The core principle of the FFX forming process lies in the unique design of the opening section, which enables the equipment to produce welded pipes with various diameters and cross-sectional shapes without the need for frequent mold changes. The steel strip is gradually bent into a tubular shape using precise rollers and tooling, and high-frequency induction welding is applied to join the edges of the strip, forming a long pipe. After the forming, the pipe goes through a sizing section to ensure dimensional accuracy and surface smoothness.

Steel Strip Feeding: The unwinder feeds the steel coil into the production line, where the steel strip is unrolled and adjusted before entering the forming section.

Forming: The steel strip is progressively bent into a circular shape by a series of forming rollers. In the opening section, the shared mold design allows for quick adaptation to different pipe diameters without mold changes.

Welding: As the steel strip is formed into a tube, the edges are welded together using high-frequency induction welding, ensuring a strong, high-quality seam.

Sizing and Straightening: After welding, the pipe passes through sizing rollers, which adjust the pipe's diameter and straighten it to meet precise specifications.

Cutting : The finished pipe is then cut to a preset length using a servo-controlled flying saw, ensuring accurate lengths.

Discharge: The cut pipes are transferred to a stacking area or packaging section via conveyor belts, ready for further processing or delivery.

Advantages of FFX Forming

Mold Savings: The shared mold design in the opening section enables quick adaptation to different pipe diameters and cross-sectional shapes without frequently changing molds, reducing mold costs.

Flexibility in Production: The equipment can be quickly adjusted according to production needs, enabling small-batch, multi-spec production to meet changing market demands.

Increased Production Efficiency: The use of high-frequency induction welding and servo-controlled cutting systems ensures the equipment runs efficiently, achieving high-speed production with minimal downtime.

Reduced Downtime: The quick adjustment of molds and production lines minimizes downtime, improving overall productivity.

Real-world Application Cases

-

Egyptian Customer - 10-inch FFX Welded Pipe Equipment

In 2023, we installed a 10-inch FFX welded pipe production line for a large pipe manufacturer in Egypt. This customer previously only produced small pipes, but with the flexibility of the FFX technology to quickly switch molds, they expanded into large structural pipe markets. Within just six months of equipment installation, they secured several large-scale infrastructure project orders, which helped them open up a new market and achieve significant profit growth. They have since placed an order for a second production line. -

U.S. Customer - Multiple 8-inch FFX Units for Octagonal Pipe Production for Solar Panels

In California, Texas, and other renewable energy markets in the U.S., several customers adopted our 8-inch FFX system to produce octagonal pipes for solar panel mounting structures. The quick switching and size consistency of FFX technology helped customers meet the high-precision, high-strength demands of the solar energy market. Currently, these products are in high demand, and the equipment is running at full capacity. Customers have provided feedback that the equipment is extremely stable, easy to debug, and has a very low failure rate.

Wide Product Application Areas

-

Solar panel supports, wind turbine tower structures

-

Building steel structures, scaffolding, curtain wall profiles

-

Electrical cable conduits, fire water pipes

-

Automotive beams, motorcycle parts

-

Furniture frames, supermarket display racks

-

Sports fitness equipment, agricultural supports, etc.

Particularly suitable for the mass production and flexible production of high-precision, high-strength pipes.

Maintenance Recommendations (Customer-Tested Summary)

-

Regularly check the servo adjustment system's operating condition to ensure adjustment accuracy

-

Inspect the cooling system of the high-frequency welding system weekly, maintaining a clean water cycle

-

Keep rollers clean and regularly fine-tune them to prevent accumulated errors

-

Replace consumables promptly, and stock spare parts to reduce downtime risks

-

Backup PLC programs and parameters quarterly to prevent data loss in case of power outages

-

It is recommended that operators undergo professional training to reduce failure rates and setup time

-

Enviar un mensaje

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!