HSS (High-Speed Steel) Circular Saw Blades are essential cutting tools in straight seam welded pipe production lines, engineered for demanding, high-speed continuous cutting operations. Crafted from premium-grade HSS materials such as M2 or M35 steel these blades offer excellent hardness, heat resistance, and wear durability, making them ideal for cutting a wide range of metal pipes including carbon steel and stainless steel.

When integrated with flying saw systems, the blades enable non-stop, precision length cutting, significantly enhancing overall production efficiency. Their optimized tooth geometry and advanced heat treatment ensure clean, burr-free cuts, minimizing the need for secondary processing. Depending on pipe material and wall thickness, blades can be customized with specialized coatings (such as TiN or TiAlN) and tooth profiles to further improve performance and extend service life.

These saw blades combine cutting stability, low noise operation, and easy maintenance, offering a cost-effective and highly reliable solution for high-speed welded tube cutting applications.

|

HSS SAEPE MENSURA LIST FERRUM

|

|

Magnitudo ODxT mm

|

|

250X1.0

|

|

250X1.2

|

|

250X1.6

|

|

250X2.0

|

|

250X2.5

|

|

275X1.0

|

|

275X1.2

|

|

275X1.6

|

|

275X2.0

|

|

275X2.5

|

|

300X1.0

|

|

300X1.2

|

|

300X1.6

|

|

300X2.0

|

|

300X2.5

|

|

300X3.0

|

|

315X1.6

|

|

315X2.0

|

|

315X2.5

|

|

315X3.0

|

|

325X1.6

|

|

325X2.0

|

|

325X2.5

|

|

325X3.0

|

|

350X1.6

|

|

350X2.0

|

|

350X2.5

|

|

350X3.0

|

|

370X2.0

|

|

370X2.5

|

|

370X3.0

|

|

400X1.6

|

|

400X2.0

|

|

400X2.5

|

|

400X3.0

|

|

425X2.5

|

|

425X3.0

|

|

425X3.5

|

|

450*2.5

|

|

450*3.0

|

|

500*3.0

|

|

500*3.5

|

|

560*3.5

|

|

560*4.0

|

|

600*3.5

|

|

600*4.0

|

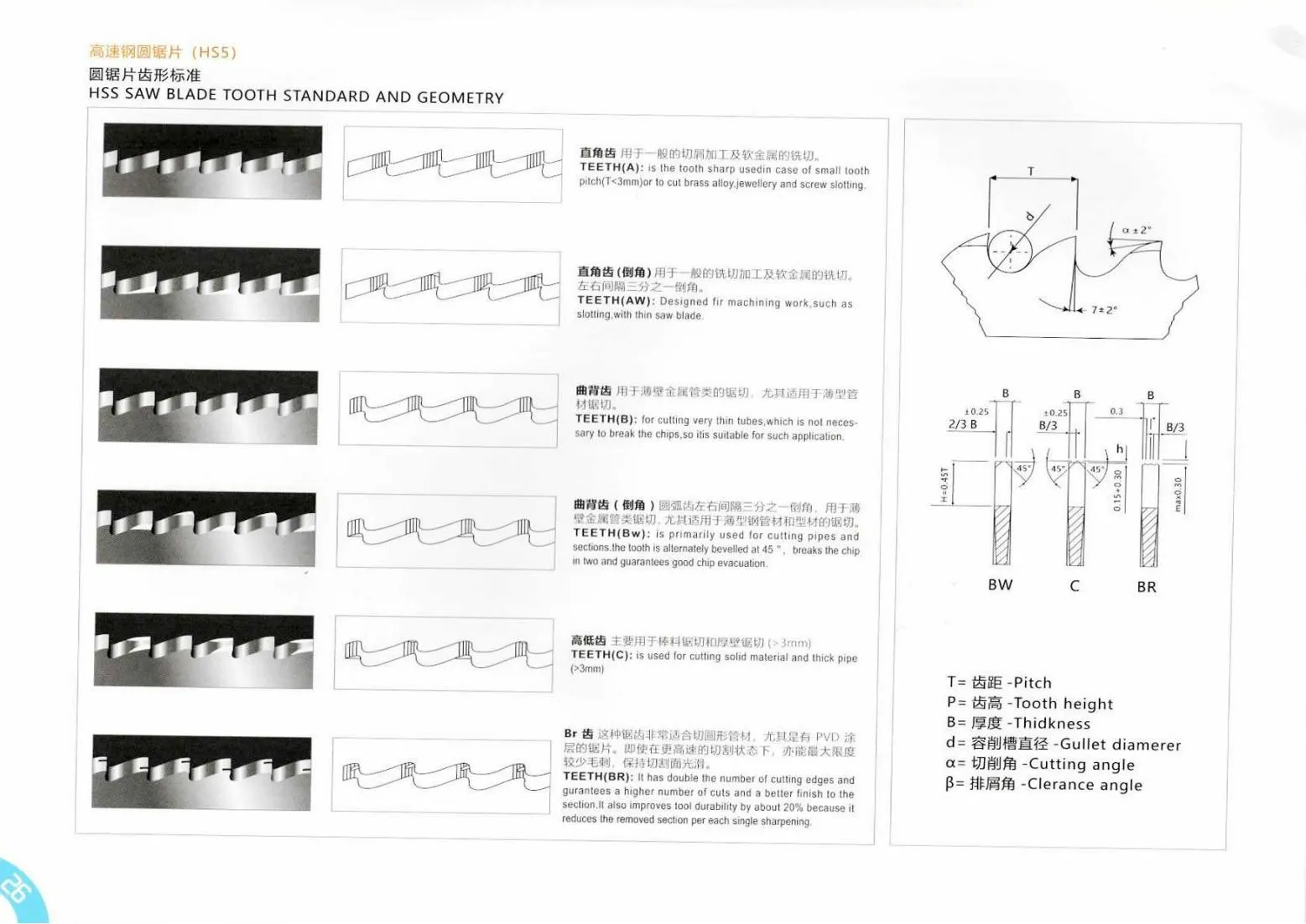

HSS Saw Blade Tooth Standard

HSS vidit ferrum ad omnia genera metallorum secanda. Hae laminae venis vaporis tractatae, TiN obductis vel M35 Cobalt Caeruleus. Vulgo Vapor agitur de laminis manu operatis machinis incisis fu- mites adhibentur. Tin obductis adhibentur machinis manu operatis ad ferro intemeratum secandum, & in semi & plene automatis ad secandum ferrum tam mitem & immaculatum. Cobalt M35 caeruleae ad materias durissimas secandas et usui maxime sunt in machinis automaticis ad sectionem producendam. Ensures reducta parte vagum et meliorem lapsum resistentia

Machinator pro maximis celeritates secandis et oneribus dente. Hae serrae laminae plumae dedicatae efficiunt quae vagum et bene gestationem resistentiae reductam in tuto collocant. Humilissima friction coefficientis, durities alta, et resistentia temperatura praestans. Utrum latis, semi-automaticis, vel applicationibus abscissorum volans, HSS vidit laminas praestantiores effectus. Auge incisis output utendo imbre nebulam vel emulsionem refrigerandi ad maximum eventum.

COGNATIO ORNATUS

Nos omnem apparatum praebet ad sectionem molendini tubi viscus:

Coil Car

Singula et duplicata capita Un-coiler & hydraulica et pneumatica Un-coiler

Peeler et tenere in volumine arm

Machina adulatione

Automatic et Semi Auto Shearer & Butt Welder

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

TUBE MOLENDUM CONSUMMATIO SECTIO PRIMA

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

PARCE partes eligere

Nostris parce partes applicare:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

Testimonium nostrum

OPERA NOSTRA

Quid nos elige?

Ducens Technology, Reliable Quality, Excellent Service!

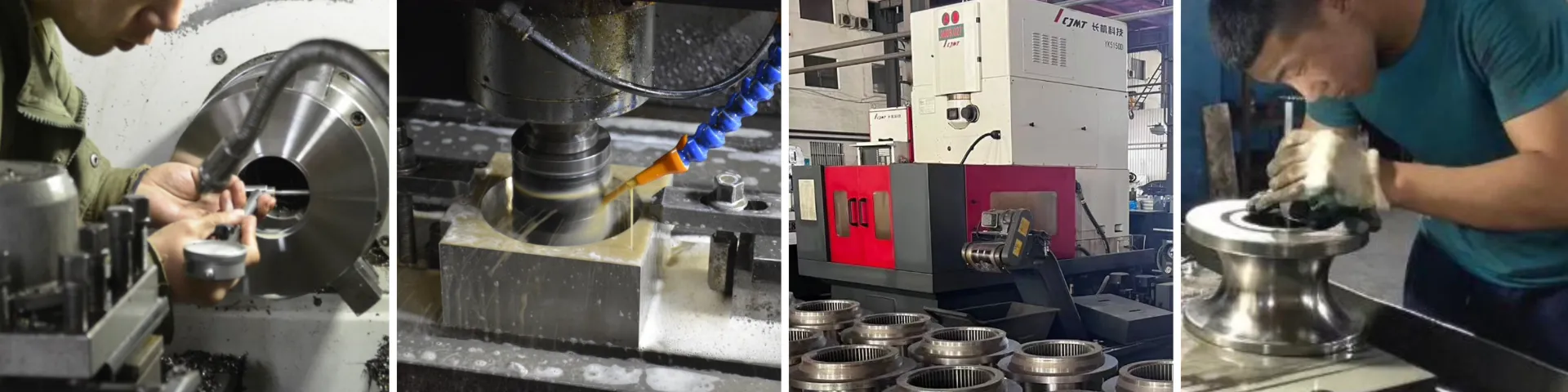

Optimized Design, High quality material select!

Caloris curatio processus spondet!

Calces cochleae revellere, orum calces copulatio et carburization.

Dentium calces exstingui.

Ratio acti stabilis, efficax et infatigabilis cum sonitu inferiori.

Summa subtilitate gerunt resistendo et longam tribulis vitam.

Tota machina Lathes, sulci Clavis a CNC cincta et molita sunt.

Our Service

Pre-venditionis officium

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

Post-Sales ministerium

1. Nos machinam trademus et documenta in tempore praebebunt ut machinam celeriter efficere possis

2. Praeparatio condiciones cum consummaveris, Ieiunium et professio nostra postsales servitii fectum ibit ad officinam tuam ut machinam instituat, manualem operantem tibi tribuat, et operarium tuum exerceat donec machinam bene operari possint.

3. Nos unum annum warantum et diuturnum technicum subsidium praebent.

4.Bene peritus & peritus baculus respondeat omnibus tuis quaestionibus Anglice et Sinice

5 .24 horae ad fectum responsum.

6. Negotium tuum cum nobis communicatio alicui tertiae parti secretior erit.

Qualitas Imperium

Unicum qualitatem habemus, quae materiam rudium materiarum bonam fac, et machinam nonumyter curet.

Tel:86-15176910262

Tel:86-15176910262