-

Tel:86-15176910262

Tel:86-15176910262

-

Пребарување

Precision Cutting Solutions: Metal Coil Processing Made Easy

Мај . 08, 2025 16:13

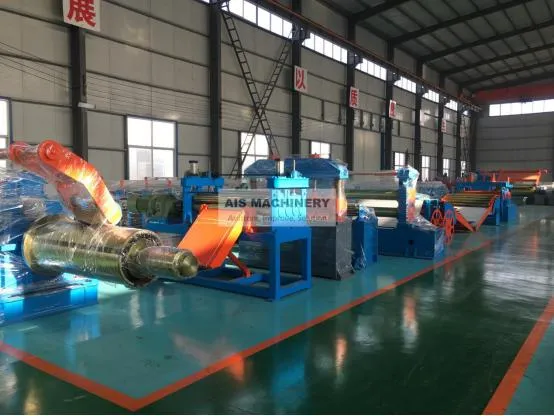

In today’s fast-paced manufacturing environment, the ability to process metal coils with high efficiency and precision is essential. Whether you're in the automotive, construction, or electronics industries, cut to length and slitting machines are critical for transforming raw metal coils into usable sheets or strips. These machines offer advanced technology for accurate cuts, increased productivity, and minimal material waste. In this article, we will explore how metal cut to length machines, stainless steel coil slitting machines, and steel coil slitting machines provide high-quality solutions for modern industries, highlighting the features, benefits, and applications of these essential tools.

Cut to Length and Slitting Machines: Efficient and Reliable Processing

The cut to length and slitting machine is a versatile tool in modern manufacturing, offering a dual-function process that can both slit wide metal coils and cut them to precise lengths. This combination significantly increases production efficiency and reduces operational costs. These machines are highly efficient in industries that require various sheet metal forms, including automotive, aerospace, and construction, where precision and speed are essential.

The cut to length and slitting machine operates in a streamlined process. First, the metal coil is unwound by an uncoiler, then it passes through a leveling system to remove any deformation, ensuring the metal is flat. Following the leveling process, the slitting function divides the coil into narrower strips of the required width. Finally, the cutting section trims the metal to the specified length, ready for further processing or shipment.

By integrating both slitting and cutting functions in one machine, businesses can save time and resources, leading to greater flexibility and faster turnaround times. Additionally, modern machines are designed with precise control systems, such as PLC automation, ensuring that both the slitting and cutting processes remain accurate, reducing errors and improving overall product quality.

Metal Cut to Length Machine: Optimizing Production with Precision

The metal cut to length machine is crucial for industries that require precise lengths of metal sheets from coils. Unlike traditional cutting methods, which often result in material waste and lower production rates, metal cut to length machines are designed to cut metal to the exact lengths needed with minimal waste. This high level of precision is achieved through advanced servo-length control systems, which allow operators to adjust the cutting length digitally, ensuring exact measurements every time.

These machines are capable of processing a wide range of metals, including carbon steel, stainless steel, galvanized steel, and aluminum, making them versatile and adaptable to various industries. The metal cut to length machine uses a high-speed shear cutting system that minimizes the cutting time while maintaining clean edges. This is especially important in applications where the surface finish of the material is critical, such as in the production of electrical enclosures, automotive parts, and building materials.

Moreover, metal cut to length machines are often equipped with automatic stacking mechanisms, which enhance production efficiency by handling large volumes of finished sheets with minimal manual intervention. The system ensures that the cut sheets are neatly stacked and prepared for delivery or further processing, saving time and reducing handling costs.

Stainless Steel Coil Slitting Machine: High-Quality Performance for Tough Materials

The stainless steel coil slitting machine is specifically designed for processing stainless steel coils, which are more difficult to handle than other types of metal due to their hardness and resistance to corrosion. As stainless steel is widely used in industries such as food processing, medical, and aerospace, stainless steel coil slitting machines must offer exceptional precision and durability to handle these challenging materials.

This machine operates in a similar manner to other slitting lines but is equipped with features that ensure the cutting of stainless steel is performed with high precision. These features include high-precision circular knives, servo motors, and automatic tension control systems to ensure consistent, smooth cuts without any deformation. Additionally, stainless steel coil slitting machines often incorporate high-speed shearing systems that reduce the processing time and improve throughput.

With the rise in demand for stainless steel products in various sectors, including kitchenware, medical devices, and architectural components, stainless steel coil slitting machines are essential in ensuring that these materials are cut to size with minimal waste and at a faster rate, meeting the high production standards required by industries worldwide.

Steel Coil Slitting Machine Price: Finding the Right Balance of Cost and Quality

One of the most important considerations when investing in steel coil slitting machines is the price. The челична серпентина машина за сечење цена can vary significantly based on the complexity of the system, the level of automation, and the size of the machine. While high-end machines with advanced features like PLC controls and automatic coil feeding systems come at a higher cost, they often deliver better efficiency, precision, and reduced operational costs over time.

For businesses looking to balance cost and performance, it's essential to consider factors such as production volume, material type, and required processing speed. A more affordable, basic машина за сечење на челични намотки may be suitable for smaller operations or for handling less complex materials, while larger manufacturers may require more advanced systems that can handle high-speed production and a variety of metal types.

When evaluating the челична серпентина машина за сечење цена, it’s crucial to also consider the long-term savings generated by investing in high-quality, durable equipment. Features like automatic tension control and integrated waste reduction systems can help reduce operational costs, making it a smart investment in the long run.

Combined Slitting: Optimizing Efficiency and Versatility

Combined slitting is an innovative approach to metal processing that combines the functionality of slitting and cutting into one streamlined process. This technique allows manufacturers to efficiently handle large coils, cutting them into narrower strips of precise lengths, ready for further production or distribution. Combined slitting offers numerous benefits, including improved production speed, reduced operational costs, and higher product consistency.

By combining slitting and cutting into a single machine, combined slitting lines allow for faster production times and more versatile material handling. This process is particularly valuable for industries that require high volumes of metal sheets, such as automotive, construction, and appliance manufacturing. Combined slitting ensures that each piece of metal is precisely cut, reducing material waste and improving the overall quality of the finished product.

The adoption of combined slitting systems allows manufacturers to scale production more efficiently, meet market demands more effectively, and reduce lead times. Additionally, this technology is highly adaptable, with many machines offering customization options for different metal types, thicknesses, and widths.

Combined Slitting FAQs

What is a cut to length and slitting machine?

A cut to length and slitting machine is an advanced tool used in metal processing to simultaneously slit wide metal coils into narrower strips and cut them to specific lengths. This dual-function process boosts efficiency and reduces operational costs.

What materials can be processed by a metal cut to length machine?

A metal cut to length machine can process a variety of metals, including carbon steel, stainless steel, galvanized steel, and aluminum, offering versatile solutions for different industries.

How does a stainless steel coil slitting machine work?

A stainless steel coil slitting machine uses high-precision circular knives and automatic tension control systems to slit stainless steel coils into narrower strips. It ensures accurate, clean cuts while maintaining the material's integrity.

What factors influence the steel coil slitting machine price?

The челична серпентина машина за сечење цена is influenced by factors such as machine size, automation level, material type, and production speed. Advanced features like PLC controls and high-speed shearing systems can increase the cost but provide long-term savings through improved efficiency.

What is combined slitting, and how does it benefit manufacturers?

Combined slitting integrates the slitting and cutting processes into one streamlined operation. It offers faster production times, reduced material waste, and higher precision, making it ideal for industries with high-volume production needs.

Поврзани производи

Поврзани вести

Испрати порака

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!