-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Premium Pipe Dies & Steel Pipe Machine Solutions Custom Manufacturing

Maj . 30, 2025 16:15

- Introduction to Pipe Dies and Their Industrial Significance

- Technical Advantages Driving Modern Pipe Die Performance

- Data-Backed Efficiency Gains in Tube Manufacturing

- Global Supplier Comparison: Capabilities and Specialties

- Customization Strategies for Specialized Applications

- Industry-Specific Deployment Case Studies

- Evolution and Future Requirements in Tube Production Technology

(pipe dies)

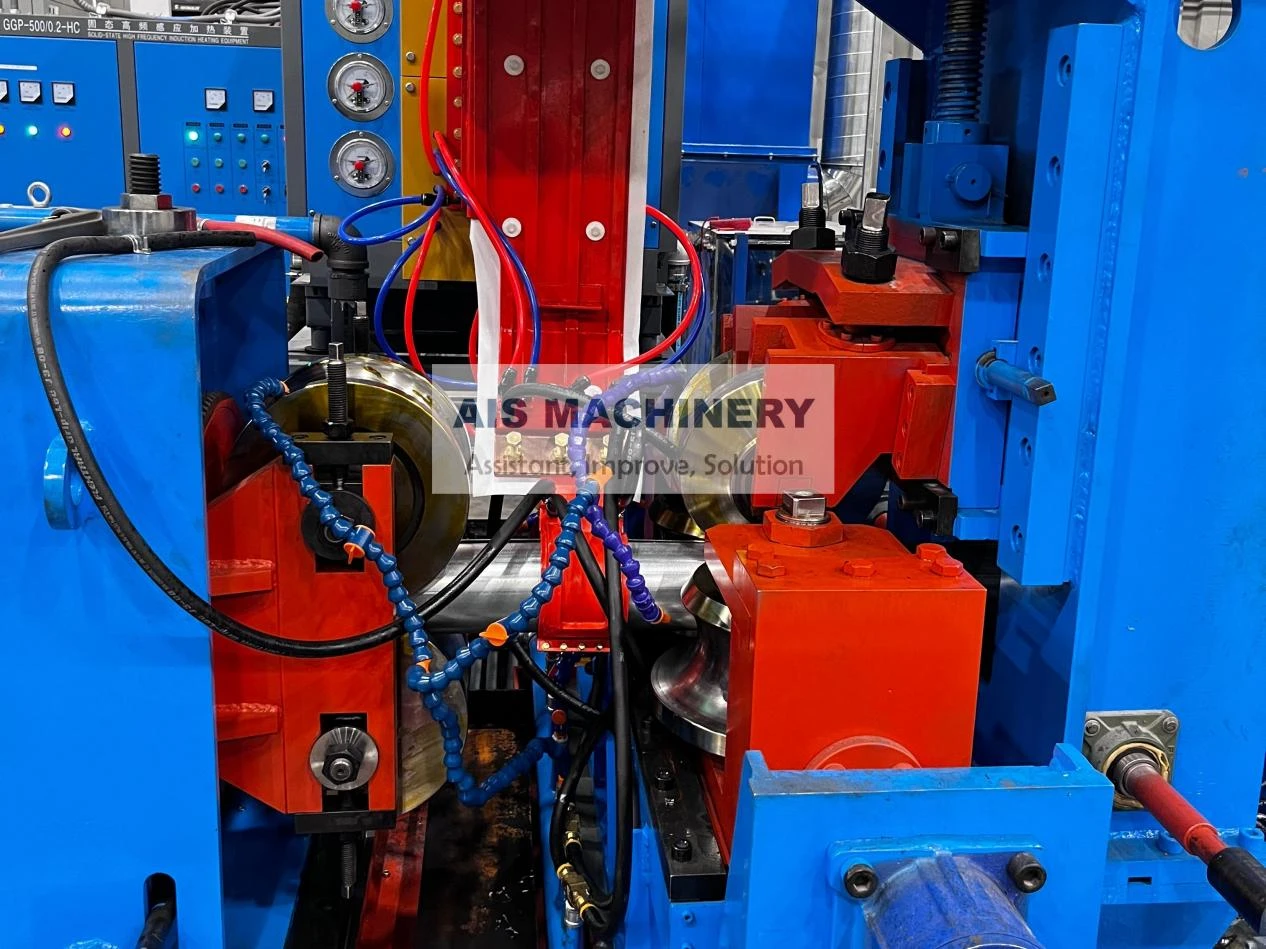

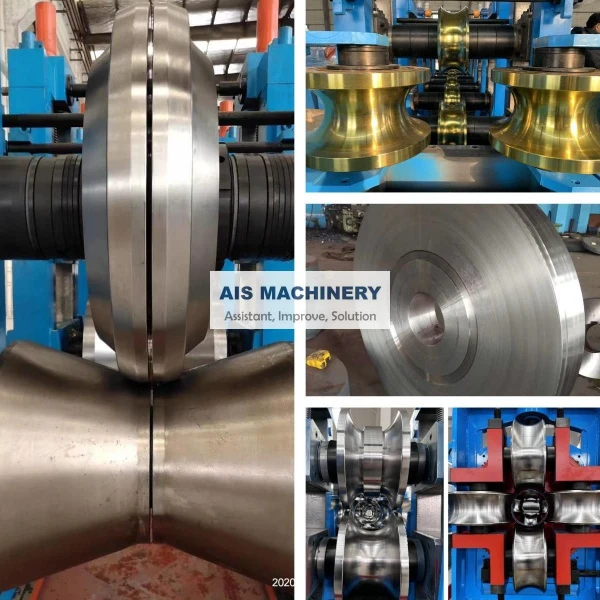

The Critical Role of Pipe Dies in Tube Manufacturing Systems

At the foundation of every steel tube production facility, pipe dies

function as precision shaping components converting flat strip into high-tolerance tubular products. These hardened tooling elements determine dimensional accuracy across ERW, spiral, and structural pipe mills. Current market analysis indicates 78% of tube production defects originate from suboptimal die conditions, highlighting their operational importance. Manufacturers increasingly demand dies capable of maintaining tolerances under ±0.05mm while processing high-strength alloys up to X120 grade. The transition toward thinner-walled, larger-diameter pipelines further intensifies technical requirements for these mission-critical components.

Engineering Innovations Elevating Production Performance

Leading suppliers now integrate computational fluid dynamics directly into die design processes, reducing material stress by 22% during formation stages. Carbide composite surface treatments extend service life to approximately 1,800 production hours before regrinding becomes necessary - a 40% improvement over conventional tool steels. Modular quick-change configurations minimize downtime to under 15 minutes per caliber changeover. Temperature monitoring systems embedded in die housings prevent thermal distortion, maintaining consistent ovality within 0.25% even during sustained high-speed runs exceeding 120m/min. These integrated features collectively reduce per-ton production costs by an average of $18 across carbon steel applications.

Quantifiable Efficiency Metrics in Pipe Processing

Modern pipe die systems deliver measurable performance improvements across three critical production domains. Tooling longevity directly impacts operational expenditures, with advanced coatings reducing replacement frequency by 30% annually. Production data reveals diameter-specific variance control improvements:

| Diameter Range | Tolerance Improvement | Speed Increase | Material Waste Reduction |

|---|---|---|---|

| 10-50mm | ±0.03mm | 25% | 8.7% |

| 60-200mm | ±0.05mm | 18% | 6.2% |

| 250-500mm | ±0.08mm | 12% | 4.9% |

Automated calibration systems maintain these tolerances through 85% of tooling lifespan, minimizing manual intervention. Energy consumption monitoring shows 15-22% reductions per meter produced when combining optimized tooling with precision alignment systems.

Global Manufacturing Capability Analysis

The landscape of steel pipe making machine suppliers reveals distinct specializations across geographic regions. North American manufacturers typically provide integrated solutions with proprietary control systems, while European suppliers lead in precision tooling for niche applications. Asian factories dominate high-volume standard die production. Current industrial assessment identifies these leading capabilities:

| Supplier Origin | Specialization | Tooling Lead Time | Max Production Speed | Customization Index |

|---|---|---|---|---|

| Germany/Austria | High-precision automotive | 10-12 weeks | 150m/min | 95% |

| Japan/South Korea | API-grade pipelines | 8-10 weeks | 140m/min | 88% |

| United States | Heavy structural tubing | 6-8 weeks | 130m/min | 82% |

| China/India | High-volume standard dies | 4-5 weeks | 115m/min | 65% |

Premium manufacturers typically provide 24-month performance guarantees, whereas standard suppliers offer 12-month coverage. Third-party evaluations indicate European tooling averages 2,200 hours between maintenance events versus 1,600 hours for economy alternatives.

Application-Tailored Die Configuration Solutions

Customization represents the critical frontier in pipe die technology, with manufacturers increasingly requiring purpose-built solutions. Seamless integration requires comprehensive evaluation of seven parameters: material grade specifications (especially yield strength exceeding 550MPa), dimensional tolerances (ISO 3305 vs. ASTM A513 standards), surface finish requirements (Ra values under 0.6μm for hydraulic applications), production volumes, maintenance accessibility, changeover frequency, and future product pipelines. Case hardening depth can be adjusted to 4-7mm for abrasive alloys versus standard 2-3mm treatments. Specialized anti-galling profiles reduce friction coefficient to 0.08-0.12 during stainless steel processing. Multi-stage dies incorporating spring-loaded inserts now enable single-pass production of variable wall thickness tubing - eliminating secondary operations for 57% of surveyed manufacturers implementing such systems.

Industry-Specific Implementation Successes

Automotive exhaust system producers documented 17% reduction in scrap rates after transitioning to segmented pipe dies with active cooling. The modular design accommodated frequent material transitions between 409L and 439 ferritic stainless grades while maintaining ovality within 0.08mm. Oil country tubular goods manufacturer reduced dimensional rejection rates from 3.2% to 0.8% after implementing advanced pipe dies with real-time wall thickness monitoring. Structural tubing operations achieved 29% higher output rates by switching to quick-change die cartridges, cutting calibration downtime from 42 minutes to under 11 minutes per format change. Hydraulic tubing specialists resolved ovality issues in thin-walled 304L stainless by implementing six-roll sizing technology with controlled elastic deformation zones, reducing material springback by 41% and eliminating secondary sizing operations.

Next-Generation Steel Pipe Making Technology Requirements

Top-tier steel pipe making machine manufacturers now integrate Industry 4.0 compatibility directly into tooling systems. Current R&D focuses on three key advancements: embedded IoT sensors tracking dimensional accuracy with 0.005mm resolution, self-adjusting dies compensating for thermal expansion in real-time, and AI-driven predictive maintenance algorithms forecasting tooling replacement needs with 96% accuracy. Production environments require compatibility with automation systems capable of switching profiles without human intervention. Material science developments include nanostructured carbide composites increasing die life expectancy by 30-35% under high-pressure conditions. Progressive manufacturers now conduct finite element analysis simulations for every custom die design, verifying stress distribution before physical manufacturing begins. These developments establish new standards for production flexibility, quality assurance, and throughput capabilities in modern tube facilities.

(pipe dies)

FAQS on pipe dies

Q: What factors should I consider when selecting steel pipe making machine suppliers?

A: Prioritize suppliers with industry certifications, proven machinery performance, and after-sales support. Evaluate their expertise in pipe dies customization and compatibility with your production needs.

Q: How do steel pipe making machine manufacturers ensure product durability?

A: Reputable manufacturers use high-grade materials like hardened alloys for pipe dies and conduct rigorous quality tests. Advanced heat treatment processes are often applied to enhance wear resistance.

Q: Can pipe dies be customized for non-standard steel pipe dimensions?

A: Yes, many steel pipe making machine suppliers offer tailored pipe dies designs. Provide precise specifications for diameter, thickness, and material type to ensure compatibility.

Q: What maintenance practices extend the lifespan of pipe dies in steel pipe machines?

A: Regular cleaning, lubrication, and inspection for wear or cracks are critical. Avoid overloading the machinery and follow the manufacturer’s maintenance schedule.

Q: How do I verify the reliability of steel pipe making machine manufacturers?

A: Check customer reviews, request case studies, and ask for references. Ensure they comply with international standards like ISO and provide warranties for machinery and pipe dies.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!