-

Tel:86-15176910262

Tel:86-15176910262

-

Search

High-Efficiency Steel Slitting Machine for Precision Processing Steel Slitting Line Machine Manufacturer

Kor . 05, 2025 06:09

- Introduction: Overview of steel slitting machine

technology and industrial significance - Market trends and data impact for steel processing

- Technical advantages and evolution in steel strip slitting solutions

- Comparative analysis: Leading steel slitting line manufacturers

- Customization options and industry-specific solutions

- Real-world applications and implementation cases

- Conclusion: The future scope for steel slitting machine applications

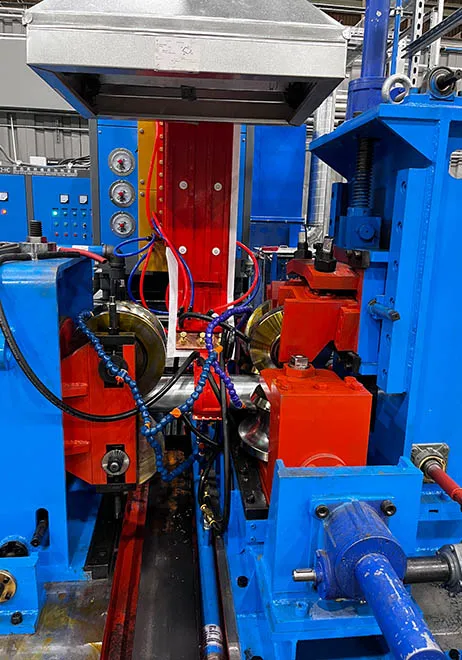

(steel slitting machine)

Understanding the Steel Slitting Machine and Its Industrial Role

The steel slitting machine is an essential equipment in the global metalworking and coil processing industry. Responsible for precisely slicing wide steel coils into narrower strips, these machines support industries such as automotive manufacturing, construction, appliance production, and electrical engineering. With the rapid growth of global steel demand—world crude steel production reached 1,955 million metric tons in 2021—efficient coil processing systems play a pivotal role in driving downstream applications. The significance of steel strip slitting machines lies in their ability to deliver high-speed, accurate, and cost-effective material preparation, optimizing supply chains and minimizing waste. Stainless steel coil slitting machines further enhance productivity and versatility, adapting to diverse material types and thicknesses, from ultra-thin foils to heavy-gauge coils.

Statistical Trends: Data-Driven Evolution in Steel Processing

Recent statistics highlight an evolving landscape for the steel slitting machine market, propelled by automation, versatility, and digital monitoring technologies. According to industry reports, the global demand for steel processing equipment is projected to surpass $138 billion by 2027, with a CAGR of approximately 5.2% between 2022 and 2027. The Asia-Pacific region, led by China, India, and South Korea, has emerged as the fastest-growing market, accounting for over 70% of new installations of steel slitting line machines.

Increasing adoption of high-tensile steel and stainless steel strips in the electric vehicle and renewable energy industries is a major driving force. In 2022, more than 40% of new stainless steel coil slitting machine orders were directed towards energy and transportation sectors. Technological improvements have resulted in machines boasting output speeds above 200 meters per minute and material thickness handling capabilities ranging from 0.1 mm to 12 mm, enabling greater flexibility for end-users. The integration of in-line edge trimming, scrap choppers, and automated tension control systems further enhances the efficiency of the slitting process.

Advanced Engineering: Technical Advantages of Modern Slitting Solutions

Modern steel strip slitting machines incorporate a range of technological advancements that ensure precision, repeatability, and low operational downtime. Driven unwinding systems, computerized blade setup, and automatic coil loading and unloading are now standard features in leading models. Laboratories have documented edge tolerances as tight as ±0.05 mm for premium steel slitting line machines, minimizing user-side finishing post-processing.

Notable technical innovations:

- Servo-driven Slitter Heads: Enhance slit accuracy and reduce set-up times.

- Automatic Blade Positioning Systems: Improve operator safety and decrease changeover intervals to less than 15 minutes for multiple product types.

- Advanced Tension Control: Guarantees consistent coil quality and reduces the risk of surface scratching.

- Energy Management Technology: Lowers power consumption by up to 18% per processed ton compared to legacy systems.

- Integrated Scrap Handling: Allows for clean, efficient disposal of edge and center trim without manual intervention.

Manufacturer Comparison: Performance and Feature Analysis

The global premium market for steel slitting machines is led by a select group of established manufacturers, each offering distinctive strengths. The following table presents a concise comparison of leading suppliers based on slitting speed, machining accuracy, applicable material thickness, energy consumption, and customization flexibility:

| Manufacturer | Max Speed (m/min) | Min Slit Width (mm) | Blade Positioning | Material Thickness Range (mm) | Energy Consumption (kWh/ton) | Customization Capability |

|---|---|---|---|---|---|---|

| FIMI Group | 400 | 8 | Automatic | 0.18-8.0 | 14.2 | Extensive (fully modular) |

| ANDRITZ Metals | 350 | 6 | Robotic/Auto | 0.2-12 | 13.5 | High (project-based design) |

| GEORG | 250 | 4 | Manual/Auto | 0.1-6.0 | 15.1 | Partial (semi-custom) |

| Delta Steel Technologies | 300 | 10 | Manual | 0.25-9.0 | 16.0 | Moderate |

Conclusion from the comparison: Suppliers such as ANDRITZ and FIMI offer the highest degree of automation and adaptability, vital for large-scale steel service centers. GEORG, meanwhile, is renowned for specialized projects, particularly in electrical steel applications. Slitting speed, positioning automation, and energy savings remain major differentiators in buyer selection.

Industry-Focused Customization: Tailoring Steel Slitting Solutions

Manufacturers now prioritize offering flexible and scalable custom configurations for their steel slitting machines to cater to unique industry requirements. Options such as premium carbide or HSS blades, edge conditioning modules, strip stacking robots, and in-line thickness measurement systems are engineered for specific sectors.

Customization strategies include:

- Automotive-grade steel processing with high flatness and burr-free edges for safety-critical parts.

- Electrical steel slitting machines equipped for ultra-narrow tolerance slits (used in transformer and motor lamination production).

- Food-grade stainless steel coil slitting for hygienic applications with enhanced surface protection and minimal contamination risks.

- Heavy gauge and multi-strand slitting for construction and shipbuilding steels.

Practical Applications: Real-World Use Cases

Across sectors from infrastructure to high-volume manufacturing, steel slitting machines play a pivotal role in enabling rapid, cost-effective coil processing. Below are notable application cases that demonstrate the performance and versatility of contemporary steel slitting technology:

- Automotive Tier-1 Supplier, Germany: Integrated stainless steel coil slitting line handles 12,000 tons/year, with auto-banding, inline oiling, and stacking. Achieved scrap reduction by 15% and labor cost savings of 12% compared to standard lines.

- Renewable Energy, Japan: Dedicated electrical steel slitting machine installed for photovoltaic and wind generator core production, with slit tolerance of ±0.04 mm. Processing throughput improved by 28% over legacy equipment.

- Construction Steel Distributor, India: Deployed high-tension steel strip slitting machine with direct-to-shearing integration, reducing defects and enabling same-day delivery for over 100 coil specifications per month.

- White Goods Manufacturing, USA: Retrofit stainless steel coil slitting machine supports multiple coating types and substrate widths, with scheduled remote monitoring and predictive maintenance, reducing unplanned downtime by 30%.

The Future of Steel Slitting Machine Innovation and Industry Impact

Steel slitting machine technology continues its upward trajectory, driven by demands for higher precision, automation, and data-driven process optimization. The adoption of digital twins, real-time IoT-based monitoring, and predictive analytics is anticipated to reshape future equipment landscapes. As users embrace these innovations, the steel strip slitting machine will further solidify its status as the backbone of advanced metal processing.

Looking ahead, energy-efficient models, remote diagnostics, and AI-driven quality assurance will define the next decade’s investments. The convergence of eco-friendly design principles with industrial-scale versatility will enable both sustainability and productivity gains for all steel-consuming industries. By responding to evolving market demands and delivering configurable solutions, the steel slitting machine will remain indispensable across the global value chain.

(steel slitting machine)

FAQS on steel slitting machine

Q: What is a steel slitting machine used for?

A: A steel slitting machine cuts wide steel coils into narrower strips. It ensures high precision and efficient processing. This equipment is vital in the steel processing industry.Q: How does a steel strip slitting machine work?

A: The machine uses rotary knives to slit steel strips into desired widths. The strips are then rewound into coils. This process increases productivity and material utilization.Q: What types of materials can a stainless steel coil slitting machine handle?

A: It primarily slits stainless steel coils but can also process other metals like aluminum. The machine is designed to handle varying thicknesses. Its robust build ensures precision and durability.Q: What are the main components of a steel slitting line machine?

A: Key components include the uncoiler, slitter, and recoiler. Additional elements may feature tensioners and coil cars. Each part ensures smooth material feeding and accurate slitting.Q: Why choose a dedicated steel slitting line machine for industrial applications?

A: A steel slitting line machine offers high speed and precision for mass production. It reduces labor costs and increases efficiency. This makes it ideal for continuous steel coil processing.Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!