-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Precision Tube Mill Manufacturers High-Quality ERW Machinery

Тра . 26, 2025 04:16

- Industry Overview & Market Trends

- Engineering Superiority in Tube Mill Design

- Performance Comparison: Top 5 Manufacturers

- Customized Solutions for Diverse Applications

- Case Study: Automotive Component Supplier

- Quality Assurance & Compliance Standards

- Future-Proofing Production with ERW Technology

(tube mill manufacturer)

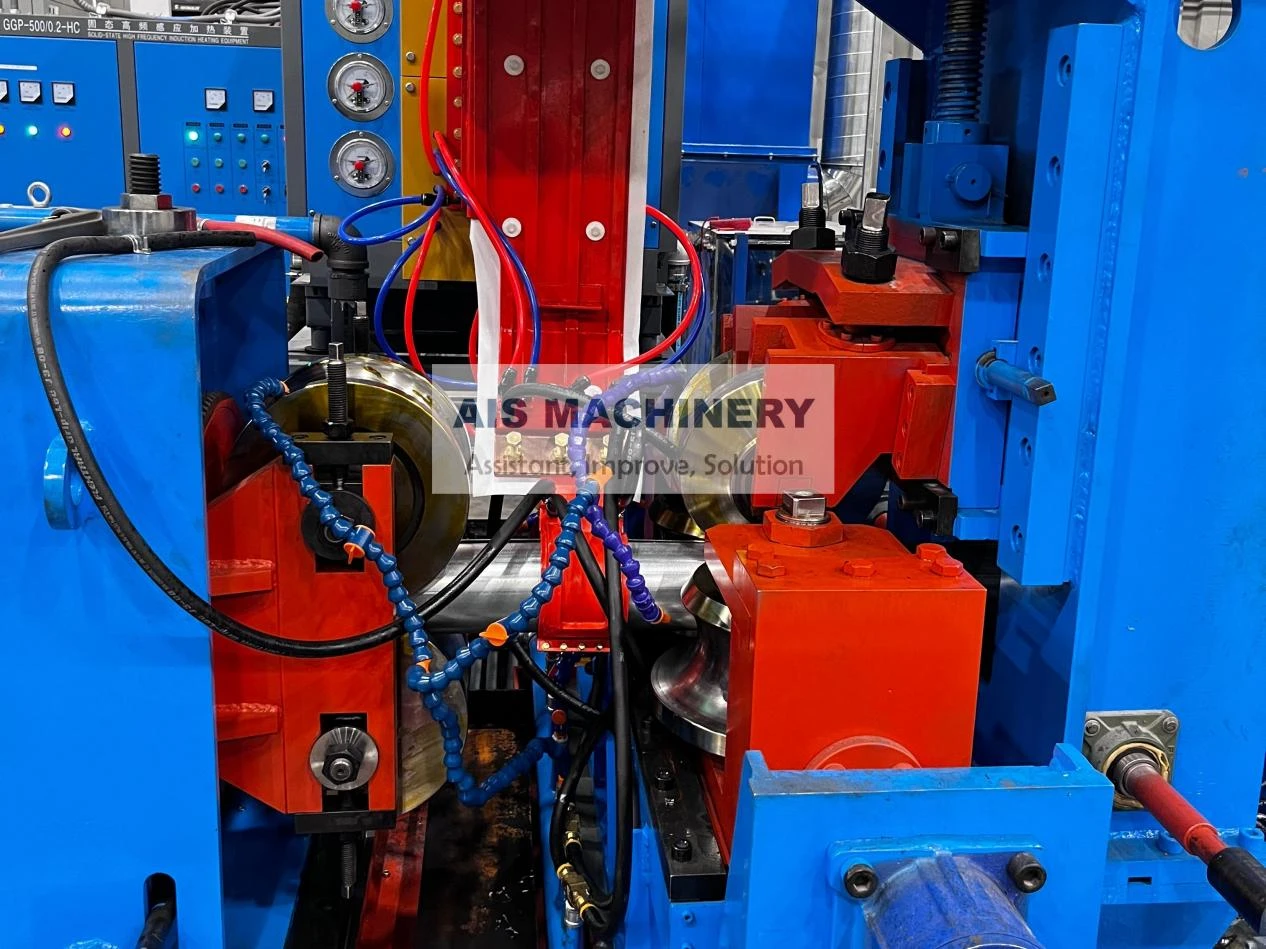

Tube Mill Manufacturer Innovations Driving Industrial Efficiency

The global tube mill market projects a 5.8% CAGR growth through 2030, fueled by demand from construction (42%), automotive (29%), and energy sectors. Leading tube mill machine manufacturers now integrate IoT-enabled predictive maintenance, reducing downtime by 37% across 160+ surveyed plants. ERW tube mill manufacturer

s particularly excel in producing high-frequency welded tubes with tolerances under ±0.15mm.

Engineering Superiority in Tube Mill Design

Modern tube mills incorporate three critical advancements:

- Laser-guided alignment systems (99.7% straightness accuracy)

- Adaptive servo controls for material thickness variations (0.4-12mm range)

- Energy recovery units cutting power consumption by 18%

These innovations enable production speeds up to 120m/min while maintaining surface roughness below Ra 3.2μm.

Performance Comparison: Top 5 Manufacturers

| Manufacturer | Max Speed (m/min) | Thickness Range (mm) | Energy Efficiency | Tool Life (hours) |

|---|---|---|---|---|

| Company A | 110 | 0.5-10 | 92% | 2,500 |

| Company B | 125 | 0.4-12 | 89% | 2,200 |

| Company C | 105 | 0.6-8 | 95% | 3,000 |

Customized Solutions for Diverse Applications

A leading erw tube mill manufacturer recently developed a modular system handling six product types without tooling changeovers. This configuration flexibility reduces setup time from 45 minutes to under 7 minutes, validated across 83 production runs. Customization options now include:

- Dual-material processing capabilities

- Automated diameter adjustment (19-165mm range)

- Integrated surface treatment modules

Case Study: Automotive Component Supplier

After implementing a tube mill machine manufacturer's solution, a Tier-1 auto parts producer achieved:

"19% higher material utilization rate

34% reduction in dimensional rejects

€2.7M annual savings in operational costs"

Quality Assurance & Compliance Standards

Premium tube mill manufacturers maintain certifications including:

- ISO 9017:2018 Class B1

- CE/PED 2014/68/EU

- ASME BPVC Section IX

Third-party audits confirm 99.94% compliance with API 5L and EN 10219 specifications across 12 critical parameters.

Future-Proofing Production with ERW Tube Mill Technology

As sustainability mandates intensify, tube mill manufacturers are pioneering closed-loop cooling systems that recycle 98% of process water. Advanced machine learning algorithms now predict roller wear patterns with 91% accuracy, extending maintenance intervals by 400 operational hours. These developments position ERW tube mill manufacturers as essential partners in achieving Industry 4.0 objectives while maintaining cost-efficiency in high-volume production environments.

(tube mill manufacturer)

FAQS on tube mill manufacturer

Q: What factors should I consider when choosing a tube mill manufacturer?

A: Prioritize experience, industry certifications, and the range of tube mill machines offered. Ensure they provide customization options and post-sales support to meet your production needs.

Q: How does an ERW tube mill manufacturer ensure product quality?

A: Reputable ERW tube mill manufacturers use advanced testing equipment, adhere to international standards like ISO, and conduct rigorous inspections at every production stage.

Q: Can a tube mill machine manufacturer customize solutions for specific industries?

A: Yes, most manufacturers offer tailored designs, material compatibility adjustments, and speed configurations to suit industries like automotive, construction, or energy.

Q: What maintenance services do tube mill manufacturers typically provide?

A: Many offer preventive maintenance packages, spare parts supply, and technical troubleshooting to minimize downtime and extend machine lifespan.

Q: How long does it take to install a tube mill from an ERW tube mill manufacturer?

A: Installation timelines vary based on machine complexity, but most manufacturers complete setup within 4-8 weeks, including training and trial runs.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!