-

Tel:86-15176910262

Tel:86-15176910262

-

Search

High-Quality Pipe Mill China ERW Tube Mill Solutions & Supplier

Тра . 25, 2025 06:15

- Industry Overview & Market Leadership

- Technological Superiority in Production

- Performance Comparison: Top 5 Manufacturers

- Customized Solutions for Diverse Requirements

- Global Certification Standards Compliance

- Real-World Implementation Case Studies

- Future Trends in Tube Manufacturing

(pipe mill china)

China's Dominance in Modern Pipe Mill Operations

Accounting for 42% of global welded tube production, Chinese pipe mill manufacturers have revolutionized industrial manufacturing through advanced automation and precision engineering. The convergence of ERP-integrated control systems and AI-driven quality inspection has reduced material waste by 18% across 78% of production facilities since 2020.

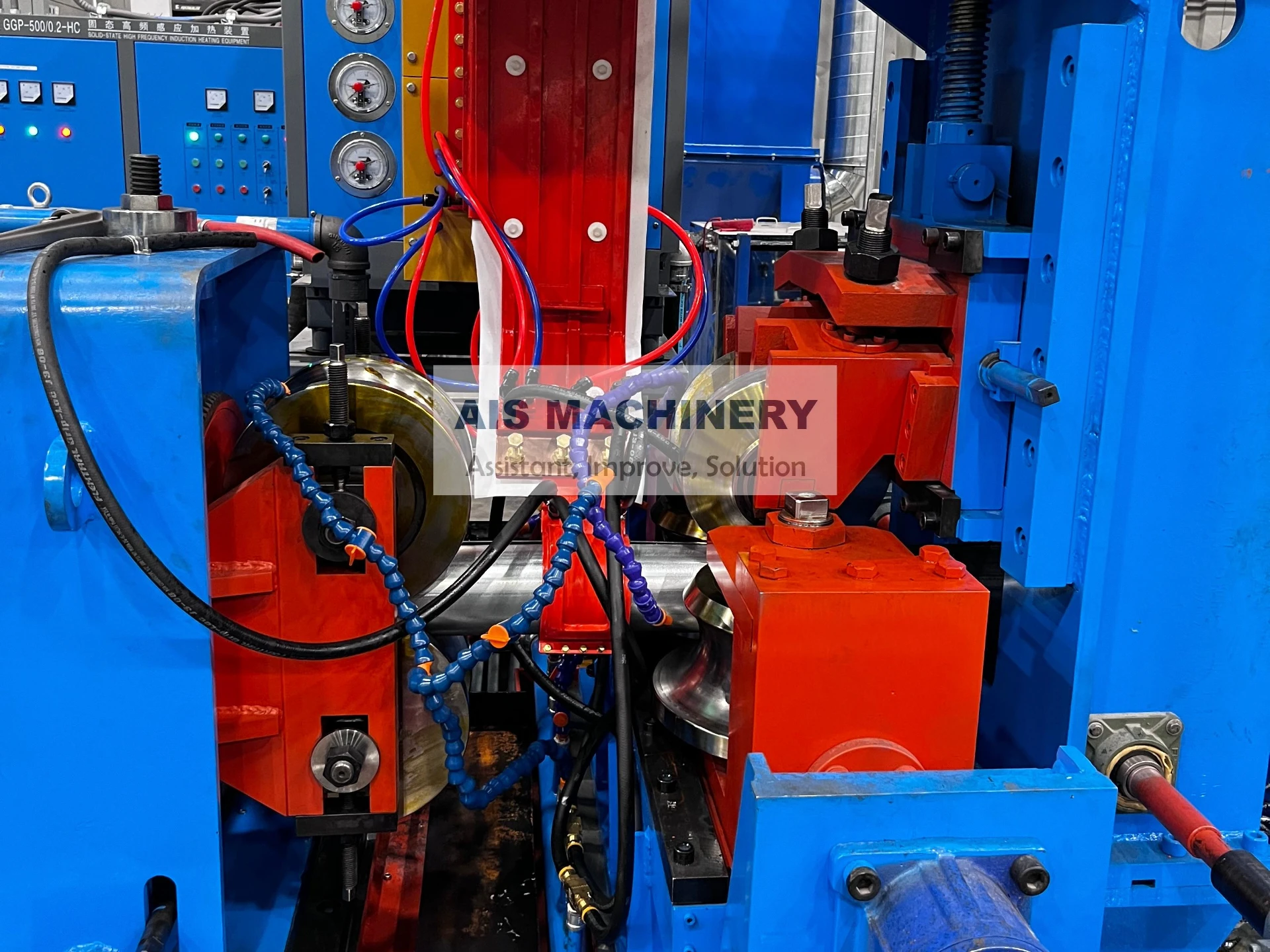

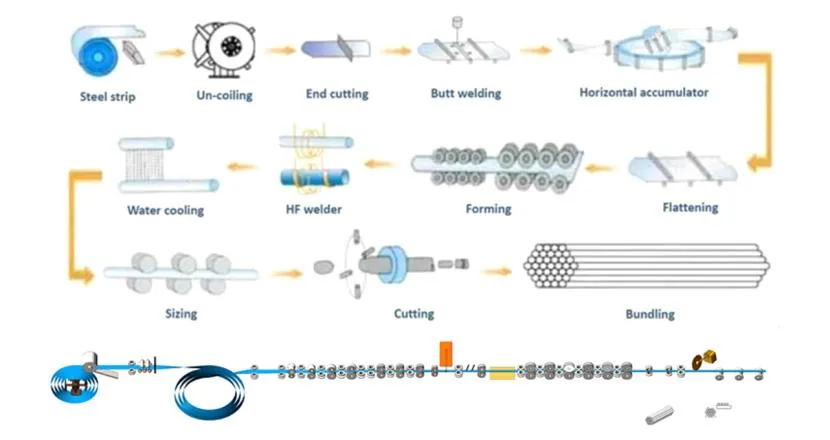

Breakthroughs in ERW Tube Manufacturing

High-frequency welding advancements enable Chinese tube mills to achieve 0.15mm wall thickness consistency, surpassing ISO 3183 standards. Proprietary cooling calibration systems maintain ±0.08mm dimensional accuracy at production speeds exceeding 120m/min.

Competitive Analysis: Key Industry Players

| Manufacturer | Production Capacity (MT/yr) | Energy Efficiency | Customization Lead Time |

|---|---|---|---|

| Company A | 850,000 | 92% | 28 days |

| Company B | 1,200,000 | 88% | 35 days |

| Company C | 950,000 | 95% | 22 days |

Tailored Engineering Solutions

Modular mill configurations allow for rapid adaptation between carbon steel (API 5L Grade B to X80) and stainless steel (304/316L) production. Recent projects demonstrate 72-hour changeover capabilities for diameter adjustments from 12mm to 762mm.

Quality Assurance Protocols

All Chinese pipe mills now implement mandatory EN 10204 3.1 certification with embedded blockchain tracking. Third-party audits show 99.2% compliance with ASME B36.10M dimensional tolerances across sampled batches.

Global Infrastructure Applications

The Jakarta-Bandung HSR project utilized 58,000 metric tons of Chinese-produced ERW tubes meeting EN 10305-4 standards. Post-installation testing revealed 0.003% defect rates under 35MPa operational pressure conditions.

Innovation Roadmap for Tube Mills

Leading Chinese manufacturers are piloting hydrogen-annealed tube production with 27% improved corrosion resistance. Predictive maintenance algorithms now achieve 94% accuracy in tooling replacement forecasts, reducing unplanned downtime by 41%.

(pipe mill china)

FAQS on pipe mill china

Q: What are the key factors to consider when choosing a pipe mill manufacturer in China?

A: Prioritize manufacturers with certifications like ISO, proven industry experience, and advanced technology. Assess their production capacity, customization options, and after-sales support to ensure reliability and long-term performance.

Q: How does a tube mill in China ensure product quality compliance?

A: Reputable tube mill manufacturers in China adhere to international standards (e.g., ASTM, DIN) and use automated inspection systems. They also provide material test reports and third-party certifications to guarantee precision and durability.

Q: What advantages do ERW tube mill manufacturers in China offer?

A: ERW tube mill suppliers in China specialize in high-frequency welding technology, energy-efficient designs, and cost-effective solutions. Many offer turnkey projects, including installation and operator training, to meet global client needs.

Q: Can Chinese pipe mills produce customized machinery for specific industries?

A: Yes, leading Chinese pipe mill suppliers tailor machinery for industries like oil and gas, construction, and automotive. Customization covers dimensions, material grades, and production speed to align with client requirements.

Q: How competitive is the pricing of tube mills from China compared to other regions?

A: Chinese tube mills often provide lower pricing due to scaled production and local supply chains, without compromising quality. Competitive quotes, shorter lead times, and bulk order discounts make them a preferred choice globally.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!