-

هاتف: 86-15176910262

هاتف: 86-15176910262

-

يبحث

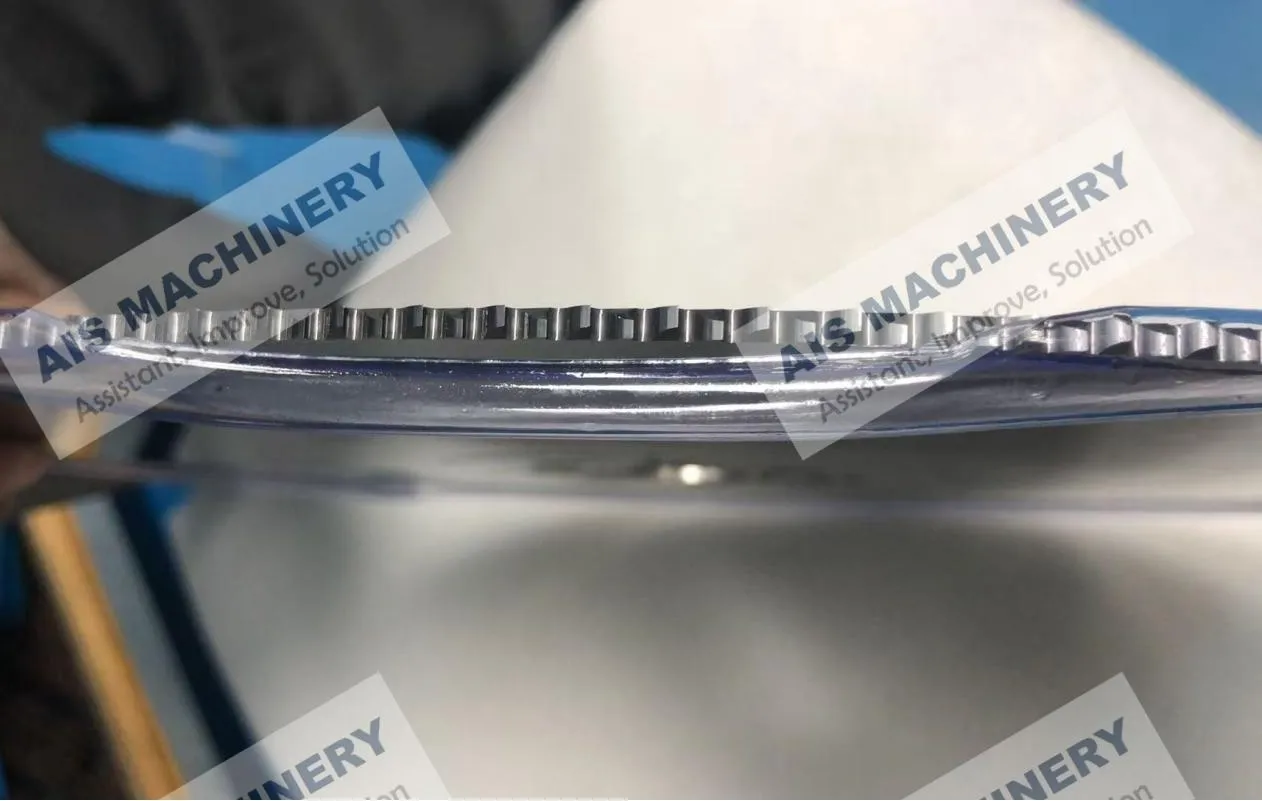

HSS Saw Blade Mounting

يونيو . 10, 2025 16:20

Proper installation of شفرات المنشار الدائرية من الفولاذ عالي السرعة forms the bedrock of efficient tube mill operations. The mounting process begins with meticulous arbor inspection – any burrs, grease residues, or scoring on spindle surfaces exceeding 0.005mm must be addressed immediately. When handling premium M35-grade hss circular blade components, operators wear cotton gloves to prevent acid transfer from skin contact, which accelerates corrosion. Critical dimensional verification includes confirming bore-to-arbor clearance , blade thickness compatibility with flange widths, and ensuring arbor threads are undamaged. Pre-installation protocols mandate checking blade certification documents for heat treatment batch numbers and verifying tooth geometry matches the pipe material – acute angles for stainless steel, trapezoidal designs for carbon steel. This preparatory rigor prevents microscopic misalignments so that avoid catastrophic failures at cutting speeds.

Tube Mill-Specific Installation for HSS Circular Blades

Continuous production environments demand specialized mounting approaches for شفرة المنشار عالية السرعة systems. In flying saw applications, hydraulic clamping forces must exceed operational torque to prevent slippage during acceleration/deceleration cycles. Dual-keyed arbors with diamond-coated contact surfaces provide positive drive engagement, while temperature-compensating flange designs maintain uniform pressure across the certain operational range. When installing TiAlN-coated blades for stainless pipe cutting, technicians use laser alignment tools to achieve axial runout – critical for preventing coating delamination. The integration of vibration-dampening collars between flanges absorbs harmonic oscillations during entry/exit cuts, extending blade life in high-frequency ERW tube mills. These protocols transform raw blade potential into sustained cutting excellence.

Precision Alignment Techniques for HSS Circular Blades

Achieving surgical accuracy requires mastering blade positioning science. Dial indicators mounted on magnetic bases measure radial runout at four quadrants, with adjustments made via precision-ground shims no thicker than 0.01mm. For شفرات المنشار الدائرية من الفولاذ عالي السرعة exceeding 650mm diameter, thermal growth compensation algorithms calculate optimal cold-runout settings based on material-specific cutting temperatures. Blade tracking verification employs optical tachometers to confirm tooth path consistency across the entire revolution. Crucially, the blade must be tensioned through controlled bolt-tightening sequences – using calibrated torque wrenches in crisscross patterns at a certain amountincrements of final specification . This eliminates flange distortion that causes premature tooth chipping in heavy-wall pipe cutting.

Operational Safety and Maintenance Protocols of Hss Saw Blade

Safe hss circular blade performance hinges on rigorous post-mounting verification. Before operational testing, technicians conduct tap tests with brass rods to detect abnormal resonant frequencies indicating stress fractures. Initial test cuts follow a graduated protocol: Real-time monitoring includes infrared thermography to identify hot spots exceeding 300°C – the threshold where HSS metallurgy begins degrading. Scheduled maintenance involves torque rechecks after cuts, followed by quarterly flange resurfacing to maintain surface finish. Blade storage mandates climate-controlled environments at 40-50% humidity, with vertical suspension on dedicated racks preventing tooth damage. These measures ensure the شفرة المنشار عالية السرعة delivers its full cut lifespan in demanding tube mill environments.

FAQs about HSS Saw Blade Mounting

Why is arbor surface finish critical for hss circular saw blades?

Mirror-finish arbors prevent micro-galling that creates stress concentration points. During high-RPM operation, imperfect contact surfaces generate localized heating exceeding 600°C, causing tempering effects that reduce blade hardness HRC. Premium installations use induction-hardened arbors with tungsten carbide coatings to maintain dimensional stability under thermal cycling.

How does blade mounting affect TiN hss circular blade coating integrity?

Improper flange pressure distribution creates micro-flexing that fractures PVD coatings. For TiN/TiAlN-coated hss circular blade products, mounting requires uniform flange contact verified by Prussian blue testing.

What causes harmonic vibration in hss circular شفرة المنشارs installations?

Resonance occurs when blade natural frequency aligns with cutting force harmonics. Mounting solutions include dynamic balancers that add counterweights to specific quadrants, and tuned mass dampers integrated into flanges.

Can flange design impact hss circular saw blade lifespan?

Conical flanges tapers provide better concentricity than flat designs. For blades under 3mm thickness, electrically insulated flanges prevent galvanic corrosion between dissimilar metals. High-performance systems use carbon-fiber-reinforced flanges reducing inertia compared to steel.

Why does tooth engagement matter for hss circular blade mounting?

Incorrect angular positioning relative to feed direction creates uneven load distribution. Optimal mounting orients is that many blade teeths can engage the material simultaneously.

The precise marriage between شفرات المنشار الدائرية من الفولاذ عالي السرعة and their mounting systems represents industrial symphonics – where metallurgical excellence meets mechanical precision. From the micrometer-level arbor preparations to the calculated tightening sequences, each step transforms raw cutting potential into sustained production performance. As tube mills evolve toward thicker walls and harder alloys, the mounting science surrounding these شفرة المنشار عالية السرعة systems grows increasingly sophisticated. What begins as a simple mechanical assembly ultimately determines whether a blade achieves its theoretical cutting capacity or fails prematurely. In the high-stakes world of continuous pipe production, proper hss circular blade installation isn't just maintenance protocol – it's the foundation of competitive manufacturing, where every correctly mounted blade echoes through kilometers of flawlessly cut tubing.

المنتجات ذات الصلة

اخبار ذات صله

أرسل رسالة

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!