-

Tel:86-15176910262

Tel:86-15176910262

-

Buscar

Find the Right Tube Mill for Your Production Line

May . 12, 2025 14:45

In the world of steel pipe and tube production, a molino de tubos is the core of any efficient operation. Whether you're a manufacturer scaling up output, a contractor seeking greater control over supply chains, or an investor entering the metal processing space, sourcing the right tube mill for sale is critical.

With growing demand across industries like construction, automotive, furniture, energy, and infrastructure, tube and pipe manufacturing has become more competitive—and more technical. This guide will help you understand how a molino de tubos works, what options exist, and how to evaluate a fabricante de molinos de tubos for long-term value.

What Is a Tube Mill?

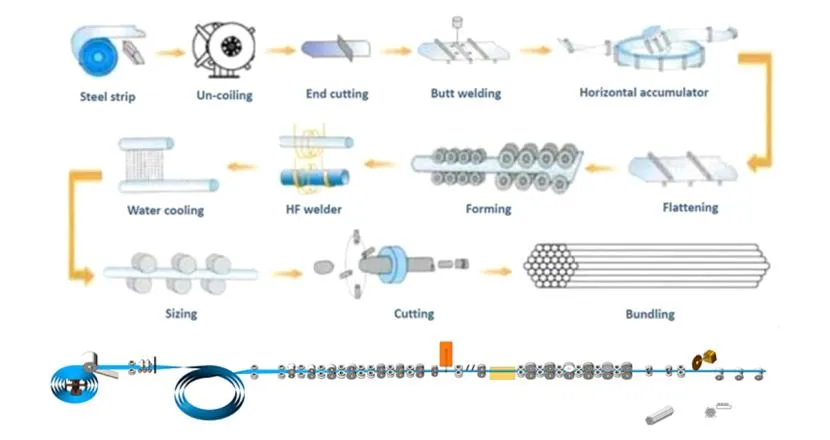

A molino de tubos is a type of roll forming machine that processes flat metal strips into welded tubes and pipes. It performs a series of operations including uncoiling, leveling, edge trimming, forming, welding, sizing, and cutting. The end product can be round, square, or rectangular tubes used in structural and industrial applications.

The tube forming process typically includes:

Uncoiler – Feeds metal strip from coils.

Forming Section – Shapes the strip into a tube through multiple rollers.

High-Frequency Welding – Joins the edges of the tube.

Squeeze Rollers – Remove excess weld bead.

Sizing Mill – Adjusts the tube’s final shape and dimensions.

Cutting Unit – Cuts the tube into precise lengths.

A modern molino de tubos offers high precision, fast changeovers, and automation for enhanced productivity.

Types of Tube Mills

There are different types of tube mills, depending on the materials, tube shapes, and end-use requirements:

1. High-Frequency (HF) Welded Tube Mill

Uses high-frequency induction to weld seams.

Ideal for carbon steel, galvanized steel, and stainless steel.

Most common type of tube mill in the market.

2. Stainless Steel Tube Mill

Designed for processing stainless steel materials.

Features wear-resistant and corrosion-resistant parts.

Used in food-grade, pharmaceutical, and chemical applications.

3. Square and Rectangular Tube Mill

Produces square/rectangular tubes directly without reshaping from round.

Reduces production steps and energy consumption.

Suitable for construction and mechanical tubing.

4. Seamless Tube Mill

Uses hot rolling and piercing to create tubes without a welded seam.

Typically more expensive and used for high-pressure pipes.

Why Buy a Tube Mill?

In-House Production Control

Owning a molino de tubos lets you control output volume, tube quality, and delivery timelines without relying on third parties.

Cost Efficiency

Once operational, your cost per meter drops significantly compared to buying from outside suppliers.

Customization Flexibility

Make tubes of different diameters, thicknesses, and lengths according to client demand.

Better Profit Margins

Sell to downstream industries or service smaller OEMs by becoming their go-to pipe and tube supplier.

How to Choose the Right Tube Mill Manufacturer

Not all tube mill manufacturers offer the same level of engineering, support, or product lifespan. When making an investment of this scale, consider the following:

Experience and Specialization

Look for manufacturers with proven success in the specific type of tube you intend to produce. A fabricante de molinos de tubos that builds for your exact industry will better understand your operational needs.

Automation and Control Systems

Modern tube mills often come equipped with PLC systems, touch-screen HMIs, servo motors, and automatic length cutting. Automation ensures consistent production, less scrap, and fewer manual errors.

Build Quality and Durability

Ask about the materials used for rollers, frames, and shafts. Chrome-plated rollers, heavy-duty gearboxes, and precision-machined components lead to less downtime and longer machine life.

After-Sales Service

A reputable fabricante de molinos de tubos offers installation, training, spare parts supply, and remote troubleshooting support.

Custom Engineering

Can the supplier adapt the tube mill to fit your plant layout, space constraints, or integrate with existing equipment?

Typical Tube Mill Prices

Here’s a general idea of tube mill pricing based on capacity and features:

|

Tube Mill Type |

Price Range (USD) |

|

Small HF Tube Mill Line |

$25,000 – $60,000 |

|

Medium-Scale Welded Tube Mill |

$80,000 – $150,000 |

|

Fully Automated Production Line |

$150,000 – $300,000+ |

|

Stainless Steel Tube Mill |

$100,000 – $250,000 |

|

Seamless Tube Mill |

$250,000 – $500,000+ |

Prices vary based on roll size range, tube thickness, production speed, and included automation features.

A quality molino de tubos can transform your business—giving you production independence, better margins, and a competitive edge in metal fabrication. But finding the right tube mill for sale requires more than comparing price tags. Focus on long-term value, technical support, and supplier reliability.

Choosing the right fabricante de molinos de tubos is just as important. The best suppliers offer more than machines—they provide engineering advice, training, and solutions that scale with your business.

Whether you're buying your first machine or expanding an existing production line, now is the time to invest in high-quality, efficient tube manufacturing technology.

Tube Mill FAQs

1. How long does it take to install a tube mill?

Depending on complexity, installation can take 2–6 weeks, including trial runs and staff training.

2. What raw materials can a tube mill process?

Tube mills typically handle carbon steel, stainless steel, galvanized steel, and aluminum. Specialized mills can process copper, brass, or titanium.

3. What maintenance does a tube mill require?

Regular lubrication, roller alignment, welding system checks, and PLC diagnostics are essential for smooth operation.

4. Can I produce different tube sizes on the same mill?

Yes, with the right roller sets and quick-change tooling systems, you can switch sizes quickly.

5. How do I finance a tube mill purchase?

Many manufacturers offer payment plans or financing options. Leasing and government industrial loans may also be available, depending on your region.

Productos relacionados

Noticias relacionadas

Enviar un mensaje

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!