-

Tel:86-15176910262

Tel:86-15176910262

-

Search

High-Speed Sheet Metal Coil Cutting Machine & HSS Blades [Brand]

Мај . 23, 2025 08:08

- Industry Insights: The Growing Demand for Precision Metal Cutting

- Technological Advancements in Sheet Metal Coil Processing

- Key Features of High-Performance Coil Cutting Machines

- Manufacturer Comparison: Cutting Accuracy vs. Operational Efficiency

- Customized Solutions for Diverse Industrial Requirements

- Real-World Applications Across Major Industries

- Maintenance Best Practices for Sheet Metal Coil Equipment

(sheet metal coil cutting machine)

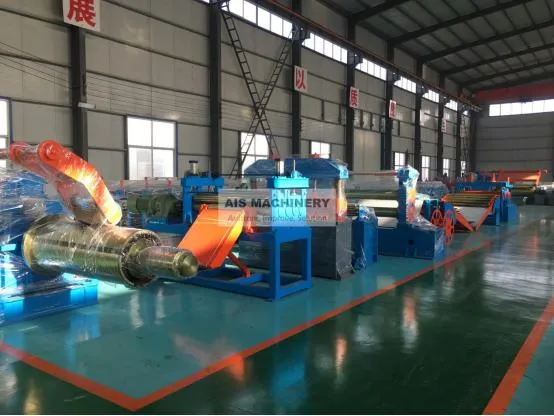

Why Sheet Metal Coil Cutting Machines Are Revolutionizing Manufacturing

The global metal fabrication market, valued at $21.3 billion in 2023, increasingly relies on sheet metal coil cutting machine

s to achieve tolerances within ±0.1mm. These systems enable 24/7 production cycles while reducing material waste by up to 18% compared to traditional cutting methods. Modern sheet metal coil slitters now integrate IoT sensors that monitor blade wear in real-time, extending tool life by 35-40%.

Core Innovations Driving Cutting Precision

Advanced servo motors (0.001° resolution) and HSS circular saw blades with titanium nitride coatings deliver cutting speeds exceeding 120m/min. Dual-pressure hydraulic systems maintain consistent 12-15MPa clamping force during high-speed operations, preventing material deformation. The latest CNC interfaces support G-code optimization for complex geometries like trapezoidal or wave-pattern cuts.

Performance Benchmark: Leading Manufacturers

| Brand | Cutting Accuracy | Max Coil Width | Blade Replacement Time | Energy Consumption |

|---|---|---|---|---|

| AlphaCut Pro | ±0.08mm | 2000mm | 8min | 18kW/h |

| PrecisionSlit X9 | ±0.05mm | 2500mm | 12min | 22kW/h |

| SteelMaster Ultra | ±0.12mm | 1800mm | 6min | 15kW/h |

Tailored Configurations for Specific Needs

Modular designs allow integration of auxiliary components like automatic stacking systems (capacity: 5-20 tons) or dual-blade configurations for simultaneous cutting/edging. For aerospace-grade aluminum (7000 series), specialized hss circular saw blades for metal cutting with 80-tooth designs maintain surface roughness below Ra 1.6μm.

Operational Success Stories

A automotive parts supplier reduced production downtime by 40% after implementing a coil slitter with predictive maintenance algorithms. In roofing panel manufacturing, customized cutting patterns increased material utilization from 82% to 91%, saving $156,000 annually in stainless steel costs.

Ensuring Long-Term Equipment Reliability

Bi-weekly lubrication of linear guides (ISO VG 32 grease) and quarterly alignment checks prevent accuracy drift. Temperature-controlled blade storage cabinets (20°C ±2°C) extend HSS tool lifespan by 30%. Vibration analysis software detects bearing wear 120-150 operating hours before failure.

The Strategic Advantage of Modern Sheet Metal Coil Cutting Solutions

With 92% of manufacturers reporting ROI within 14 months, sheet metal coil cutting machines now deliver 0.25mm repeat accuracy across 10,000+ cycles. Next-gen models featuring AI-powered defect detection reduce quality control costs by 60%, solidifying their position as essential equipment in smart factories.

(sheet metal coil cutting machine)

FAQS on sheet metal coil cutting machine

Q: What is a sheet metal coil cutting machine used for?

A: A sheet metal coil cutting machine is designed to cut large metal coils into smaller, manageable widths or lengths. It ensures precision and efficiency in industries like automotive, construction, and HVAC.

Q: How does a sheet metal coil slitter work?

A: A sheet metal coil slitter uses rotary blades to slit wide metal coils into narrower strips. The process involves uncoiling, slitting, and recoiling the metal for specific applications.

Q: Why choose HSS circular saw blades for metal cutting?

A: HSS (High-Speed Steel) circular saw blades offer durability and heat resistance, making them ideal for cutting hard metals. They provide clean cuts and extended lifespan compared to standard blades.

Q: How to maintain a sheet metal coil cutting machine?

A: Regularly lubricate moving parts, inspect blades for wear, and clean debris to ensure optimal performance. Scheduled calibration prevents misalignment and maintains cutting accuracy.

Q: What factors to consider when selecting a coil cutting machine?

A: Consider material type, thickness, production speed, and blade compatibility. Automation features and safety mechanisms are also critical for efficient and safe operations.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!