The diameter of 6 inches 168mm is already a medium-sized pipe in the straight seam welded pipe. This kind of pipe has many usage, such as solar brackets piles, ground piles, construction, etc.

This equipment can produce pipes from the smallest 2 inches 50.8mm to the largest 6 inches 168mm. A set of equipment includes all pipes. Different pipe diameters require different molds.Customers can choose from a variety of technical styles for this set of equipment, including conventional round to square, direct square for square and rectangular pipes, or FFX flexible molding technology. No matter which option you choose, we can provide a perfect solution.

2. BASIC DESIGN DATA

Design of the proposed line is based on following specification:

Raw Material Specification

|

Specification Item

|

Value/Range

|

|

Tube Diameter Range

|

Φ89mm – Φ219mm

|

|

Wall Thickness Range

|

2.0mm – 8.0mm

|

|

Strip Width Range

|

280mm – 700mm

|

|

Material Strength

|

200 – 600 MPa

|

|

Line Speed

|

15 – 40 m/min

|

|

Cutting Accuracy

|

±1.5mm

|

|

Forming Method

|

Round-to-Round / FFX / Round-to-Square

|

|

Control System

|

Siemens PLC + HMI

|

|

Total Power (approx.)

|

400 – 600 kW (based on configuration)

|

|

Operation Mode

|

Manual / Automatic switchable

|

Tube Applications

|

Industry Sector

|

Typical Uses

|

|

Steel Construction

|

Columns, brackets, structural frames

|

|

Oil & Gas Transmission

|

Gas lines, medium-pressure pipelines

|

|

Municipal Engineering

|

Firefighting pipes, water drainage

|

|

Renewable Energy

|

Solar support posts, ground mounting piles

|

|

Automotive & Machinery

|

Chassis tubes, machine arms

|

Smart Control Features

Common Issues & Solutions

|

Issue

|

Cause & Solution

|

|

Strip Deviation

|

Adjust tension, inspect guide rolls and loop control

|

|

Weld Seam Cracks

|

Increase HF power, fine-tune water cooling

|

|

Burr at Cut Edge

|

Check saw sharpness and feeding synchronization

|

|

Diameter Deviation

|

Adjust sizing roll gap and forming pressure

|

|

Unstable Tube Shape

|

Check frame rigidity, roll alignment, and strip tension

|

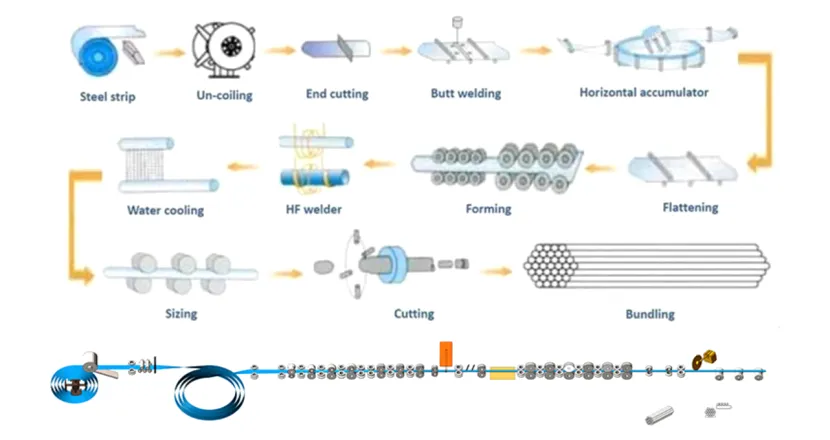

The Flow of the Production Line

{Steel Tape}→Coil car→ Uncoiler →Peeler and hold down roll→Flattener→ Strip-head Cutter and welder→Spiral accumulator→Forming section(Flattening unit +Main driving unit +Forming unit +Guide unit +squeeze roller)+ De-burr frame →→Cooling unit →→ Sizing unit and straightener →→Cutoff saw →→ Run-out table →→Straingtener machine →→Chamfer machine →→Hydro tester machine →→automatic package machine

Packaging & Shipment Details

-

|

Item

|

Packaging Description

|

|

Forming Rollers

|

Wooden crates with anti-rust oil

|

|

Forming Machine

|

Frame strapped and covered with dustproof cloth

|

|

Control Cabinet

|

Shockproof wooden box with wiring & manuals

|

|

Shipping Method

|

Modular packing, container loading or land freight

|

|

Documents Provided

|

Quality certificate, packing list, wiring diagram

|

-

Tel:86-15176910262

Tel:86-15176910262