-

Tel:86-15176910262

Tel:86-15176910262

-

Search

High-Performance Induction Coils for Efficient Power Transfer

Gus . 15, 2025 05:00

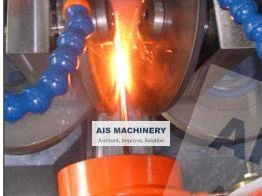

Understanding the Critical Role of induction coil in Modern Industrial Processes

The induction coil stands as a cornerstone component in numerous industrial heating applications, driving efficiency and precision across a spectrum of sectors. From sophisticated metallurgy to critical pipeline heating, its ability to generate high-frequency electromagnetic fields for non-contact heating is unparalleled. This technology is vital for processes requiring uniform heating, precise temperature control, and high energy efficiency. As industries pivot towards more sustainable and automated solutions, the demand for advanced, highly reliable induction coils continues to escalate. Understanding the intricate design, manufacturing prowess, and diverse applications of these coils is essential for optimizing industrial operations and achieving superior product quality.

Modern industrial trends emphasize energy conservation, reduced environmental impact, and enhanced process control. The inherent advantages of induction heating, facilitated by expertly engineered induction coils, align perfectly with these objectives. They enable faster processing times, cleaner operations by eliminating direct flame, and improved safety due to localized heating. This segment delves into the technical intricacies and strategic importance of this critical component, offering insights for B2B decision-makers and technical personnel aiming to elevate their operational standards.

Precision Engineering: The Manufacturing Process of an Induction Coil

The manufacturing of a high-performance induction coil is a meticulous process demanding specialized expertise and advanced machinery to ensure optimal functionality and longevity. Primarily, coils are crafted from high-conductivity materials such as oxygen-free copper (OFC), chosen for its superior electrical and thermal properties, which are critical for efficient energy transfer. The process typically begins with the precise bending and shaping of copper tubing or bar stock, often utilizing advanced CNC bending machines to achieve complex geometries required for specific applications. This ensures that the coil's shape precisely matches the work piece and desired heating pattern.

Following shaping, critical steps include brazing or welding to join coil segments, ensuring robust electrical connections and leak-proof water cooling channels – essential for managing the significant heat generated during operation. Advanced techniques like TIG welding or silver brazing are employed to guarantee joint integrity. Surface treatment, such as insulation coating (e.g., epoxy resin or ceramic), is then applied to protect the coil from electrical arcing and environmental degradation, simultaneously enhancing its dielectric strength. Each manufacturing stage adheres to stringent quality control standards, including non-destructive testing (NDT) like eddy current testing for material integrity, hydrostatic pressure testing for cooling channel leaks, and electrical insulation tests. Compliance with international standards such as ISO 9001 for quality management and ANSI standards for material specifications ensures the highest product reliability and performance, granting the induction coil a typical service life of 5 to 15 years, depending on operating conditions and maintenance.

Key Technical Parameters and Advantages of Advanced Induction Coil Systems

The performance of an induction coil is defined by a set of critical technical parameters that dictate its suitability for specific industrial applications. Understanding these specifications is paramount for engineers and procurement specialists to select the optimal coil for their needs. Key parameters include operating frequency (ranging from kilohertz to megahertz for different heating depths), power handling capacity (from kilowatts to megawatts), and cooling requirements (typically water-cooled for high-power applications). The coil's inductance (measured in microhenries) and quality factor (Q-factor) are crucial for resonance matching with the power supply and maximizing energy transfer efficiency.

The technical advantages of using an advanced induction coil are substantial. Firstly, energy efficiency, with some systems achieving over 90% conversion of electrical energy into heat within the workpiece. This translates directly into lower operational costs and reduced carbon footprint. Secondly, precision heating allows for localized heating of specific areas, minimizing distortion and preserving the integrity of non-heated regions. This is particularly beneficial in applications like soldering, brazing, and heat treatment. Thirdly, enhanced safety is a key advantage; unlike open flames or resistance furnaces, induction heating generates heat within the material itself, leading to a cooler and safer work environment with no combustion by-products. Lastly, rapid heating cycles lead to increased throughput and productivity, making these coils indispensable for high-volume manufacturing lines.

Diverse Application Scenarios and Industry Benefits

The versatility of the induction coil extends its application across a broad spectrum of industries, each benefiting from its unique capabilities. In the metallurgical sector, it is indispensable for processes like melting, forging, and hardening of metals, where precise temperature control and uniform heating are paramount for material integrity. For instance, in steel pipe manufacturing, high-frequency induction welders rely on specialized induction coils for efficient and rapid seam welding, ensuring robust and leak-proof pipes. This application highlights the coil's role in achieving both energy efficiency and high throughput.

The petrochemical industry utilizes induction coils for pipeline heating, particularly in cold environments, to maintain the fluidity of viscous substances like crude oil, preventing blockages and ensuring continuous flow. Here, the non-contact nature of induction heating prevents corrosion of the pipe's internal surfaces often associated with traditional heating methods. In the automotive industry, induction coils are used for brazing components, heat-treating engine parts, and bonding plastics, contributing to lighter, stronger, and more fuel-efficient vehicles. Even in consumer goods manufacturing, induction coils find applications in food processing, packaging, and household appliance production. The inherent advantages of energy saving, consistent heating, and robust corrosion resistance make the induction coil a superior choice for a wide array of demanding industrial environments.

Choosing the Right Partner: Manufacturer Comparison and Custom Solutions

Selecting the right manufacturer for your induction coil needs is a critical decision that impacts system performance, reliability, and long-term operational costs. Key factors to consider when evaluating manufacturers include their technical expertise, range of standard and custom solutions, adherence to quality standards, and post-sales support. Reputable manufacturers distinguish themselves through in-depth understanding of induction heating principles, material science, and precision engineering. They often offer comprehensive design services, allowing for custom induction coil solutions tailored to unique application geometries, power requirements, and operational environments.

A key differentiator for top-tier suppliers is their capability to provide robust R&D support and advanced simulation tools (e.g., Finite Element Analysis) to optimize coil design for specific heating patterns and efficiencies. They also typically boast a strong portfolio of industry certifications, such as ISO 9001, CE, and sometimes industry-specific accreditations like those for aerospace or medical applications, underscoring their commitment to quality and safety. Customization is often a necessity, not a luxury, especially for integrating induction coil technology into existing complex production lines or for highly specialized processes. A dedicated manufacturer will work closely with clients, from initial concept to final installation, ensuring the solution perfectly meets the required parameters and delivers optimal performance over its expected lifespan.

Assured Quality and Support: Standards in Practice

Experience: Real-World Application and Customer Success

Our extensive experience in delivering high-performance induction coil solutions is reflected in numerous successful deployments across challenging industrial environments. For example, a leading steel mill significantly improved its seam welding speed and quality for large-diameter pipes by integrating our custom-designed HF welder induction coils, leading to a 15% increase in production throughput and a noticeable reduction in energy consumption. Another instance involves a specialty alloy manufacturer who leveraged our bespoke induction coils for precision heat treatment, achieving exceptional metallurgical properties in their high-value components, which was previously unattainable with conventional heating. Our service team actively engages with clients post-installation, providing technical support and performance optimization, ensuring the longevity and efficiency of every induction coil delivered.

Authoritativeness: Certifications, Partnerships, and Testing

Our commitment to manufacturing excellence is underscored by our adherence to international quality and safety standards. We hold ISO 9001 certification, demonstrating a robust quality management system governing all stages from design to delivery of each induction coil. All our products comply with CE directives, ensuring they meet European safety, health, and environmental protection requirements. Our long-standing partnerships with industry leaders in power electronics and material science further enhance our authority and capability in delivering cutting-edge induction heating solutions. Rigorous internal testing, including high-frequency performance checks, dielectric strength tests (up to 20kV for some models), and thermal cycling tests, validate the performance and durability of our coils under extreme operating conditions. Our internal data shows an average energy transfer efficiency of 88-92% for our standard induction coil designs.

Trustworthiness: FAQ, Delivery, and Warranty

Transparency and reliability are core to our customer relationships. We provide clear communication on all aspects, from initial quotation to post-delivery support.

Frequently Asked Questions (FAQ):

- Q: What is the typical lead time for a custom induction coil?

A: Custom coil lead times typically range from 4 to 8 weeks, depending on complexity and material availability, following design approval. - Q: How do I ensure the correct coil design for my application?

A: Our engineering team works closely with you, utilizing detailed application data (material, geometry, heating requirements) to propose an optimized design. - Q: What maintenance does an induction coil require?

A: Primary maintenance involves ensuring the cooling water system is clean and free of blockages, and periodically checking insulation integrity.

Delivery Commitment: We understand the critical nature of timely deliveries in industrial operations. Our robust supply chain and efficient manufacturing processes allow us to offer competitive delivery cycles. Standard coils are typically dispatched within 2-3 weeks, while custom orders are delivered within the agreed-upon timeframe, often expedited for critical projects.

Quality Assurance and Warranty: Every induction coil undergoes rigorous quality control checks before leaving our facility. We offer a standard 12-month warranty against manufacturing defects, underscoring our confidence in the durability and performance of our products. Our dedicated customer support team is available to assist with any technical queries or operational challenges, ensuring seamless integration and long-term satisfaction.

Conclusion: The Future of Industrial Heating with Advanced Induction Coil Technology

The continuous evolution of induction coil technology is set to further revolutionize industrial heating processes, driving greater efficiency, precision, and sustainability. As industries worldwide strive for optimized production lines and reduced environmental footprints, the demand for sophisticated, reliable, and energy-efficient induction heating solutions will only intensify. Investing in high-quality induction coils from an experienced and authoritative manufacturer not only ensures superior performance and extended equipment lifespan but also contributes significantly to achieving operational excellence and a competitive edge in demanding markets.

References

- Rudnev, V. I., Loveless, D. L., & Cook, R. L. (2003). Handbook of Induction Heating. Marcel Dekker.

- Davies, E. J. (1990). Conduction and Induction Heating. Peter Peregrinus Ltd.

- Zinn, S., & Semiatin, S. L. (1988). Elements of Induction Heating. Electric Power Research Institute.

- ASM International. (2000). Heat Treating: Furnaces and Induction Heating. ASM Handbook Volume 4.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!