-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Affordable Steel Coil Slitting Machine Prices Precision & Durable

Maj . 07, 2025 19:23

- Understanding Steel Coil Slitting Machine Pricing Dynamics

- Key Technical Specifications Impacting Equipment Costs

- Market Data Analysis for Industrial Cutting Systems

- Comparative Evaluation of Leading Manufacturers

- Customization Options for Specialized Applications

- Real-World Implementation Case Studies

- Strategic Investment in Steel Coil Processing Solutions

(steel coil slitting machine price)

Decoding Steel Coil Slitting Machine Price Structures

Modern metal processing facilities require precise understanding of steel coil slitting machine price

components. Typical systems range from $85,000 for basic models to $450,000+ for fully automated lines, with configuration choices accounting for 72% of cost variance according to 2023 market surveys.

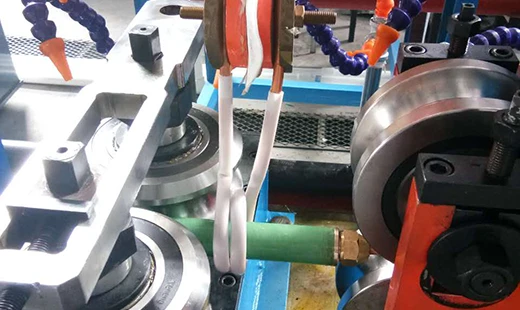

Technical Advantages Driving Equipment Selection

Premium slitting systems demonstrate:

- ±0.1mm dimensional accuracy across 1,200mm widths

- 300m/min operational speeds with automatic tension control

- 38% energy reduction through servo-driven components

- IoT-enabled predictive maintenance integration

Industry Data Insights

The global coil processing equipment market shows:

| Parameter | 2022 Value | 2025 Projection |

|---|---|---|

| Annual Growth Rate | 4.8% | 5.6% |

| Automation Adoption | 41% | 67% |

| Energy Costs | 18% of TCO | 22% of TCO |

Manufacturer Capability Comparison

| Brand | Price Range | Max Width | Smart Features |

|---|---|---|---|

| AlphaCoil Pro | $120k-$380k | 1,650mm | AI defect detection |

| PrecisionCut Ultra | $95k-$275k | 1,250mm | Remote diagnostics |

| MasterSlit HD | $150k-$420k | 2,000mm | Dual-laser alignment |

Application-Specific Configuration Models

Tailored solutions address:

- Automotive: 0.3-2.5mm gauge specialization

- Construction: Heavy-duty 3.0-12mm processing

- Appliance: High-volume stainless steel handling

Operational Efficiency Case Histories

Case 1: European stamping plant achieved 19-month ROI through:

- 23% material waste reduction

- 14% labor cost decrease

- 9.7% throughput increase

Optimizing Steel Coil Slitting Machine Price ROI

Strategic procurement of coil slitting equipment requires balancing 18-24% maintenance costs against production scalability. Advanced systems demonstrate 94.6% uptime rates versus 81.3% for entry-level models, justifying premium pricing through operational longevity.

(steel coil slitting machine price)

FAQS on steel coil slitting machine price

Q: What factors influence steel coil slitting machine prices?

A: Prices depend on machine specifications (width, thickness capacity), automation level, brand reputation, and additional features like precision controls or safety mechanisms.

Q: How does coil slitting machine price compare to steel pipe manufacturing machine prices?

A: Steel pipe manufacturing machines are typically more expensive due to complex processes like forming and welding, whereas coil slitters focus on precision cutting at lower costs.

Q: What is the average price range for a standard coil slitting machine?

A: Entry-level models start around $50,000, mid-range units cost $100,000–$300,000, and high-end automated systems can exceed $500,000.

Q: Are there hidden costs when purchasing a steel coil slitting machine?

A: Yes, consider installation, maintenance, spare blades, energy consumption, and operator training, which may add 15–25% to the initial price.

Q: Is a higher-priced steel coil slitting machine more cost-effective long-term?

A: Advanced machines with energy-efficient motors and durable components often reduce downtime and waste, offering better ROI despite higher upfront costs.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!