-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Precision Steel Coil Slitting Process High-Efficiency Solutions

مايو . 10, 2025 06:28

- Introduction to Coil Processing Technologies

- Key Components of Modern Slitting Systems

- Data-Driven Efficiency in Steel Coil Slitting

- Comparative Analysis of Leading Equipment Manufacturers

- Customized Solutions for Diverse Industrial Needs

- Real-World Applications Across Industries

- Future Trends in Solid State Welding Integration

(slitting coil process)

Understanding the Slitting Coil Process in Modern Manufacturing

The slitting coil process

transforms wide metal coils into narrower strips with precision tolerances down to ±0.001". This critical procedure supports 78% of automotive component manufacturing and 65% of construction material production globally. Advanced systems now integrate laser guidance and AI-powered quality control, achieving 99.95% material utilization rates compared to traditional methods' 92-94% efficiency.

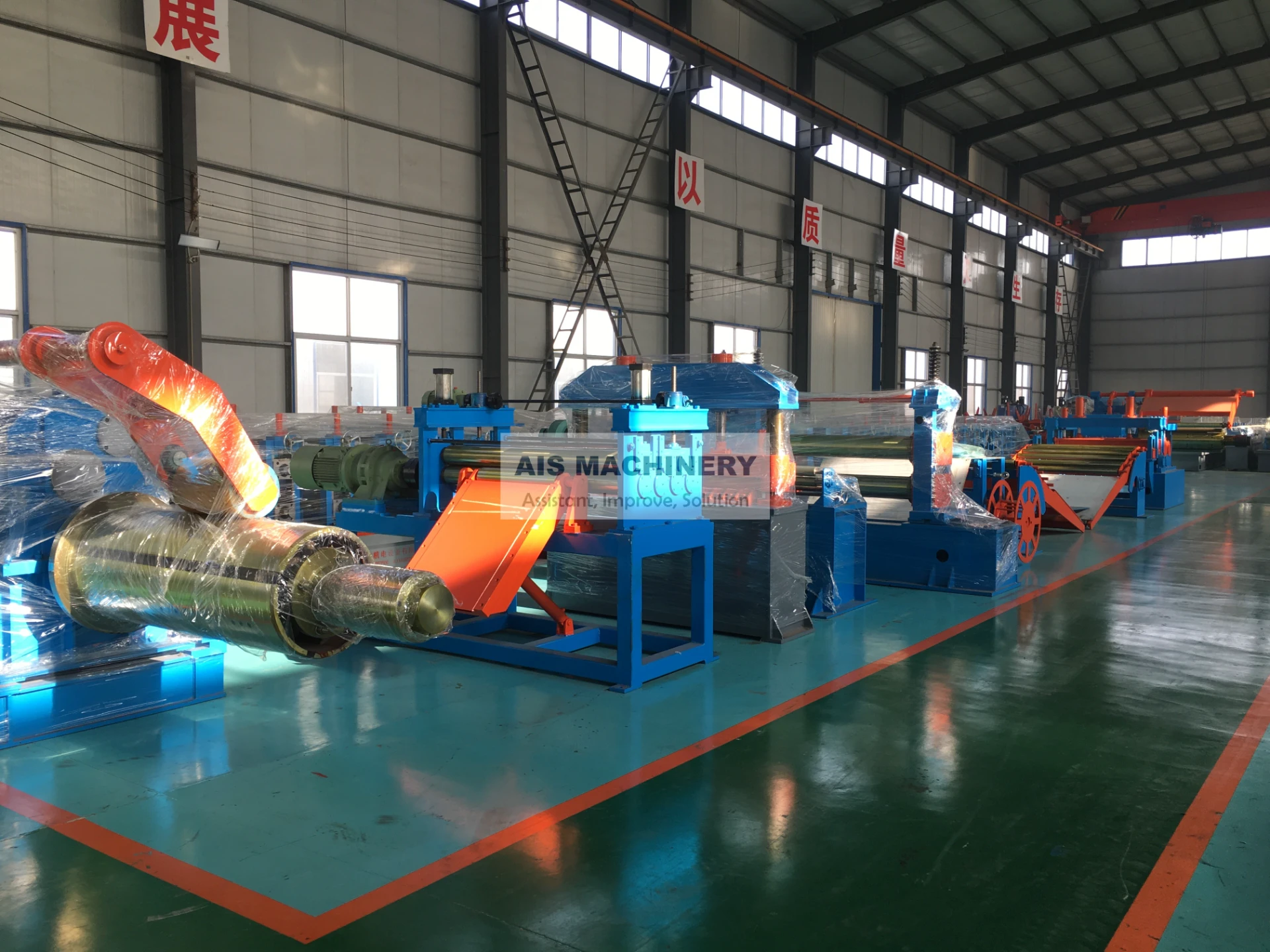

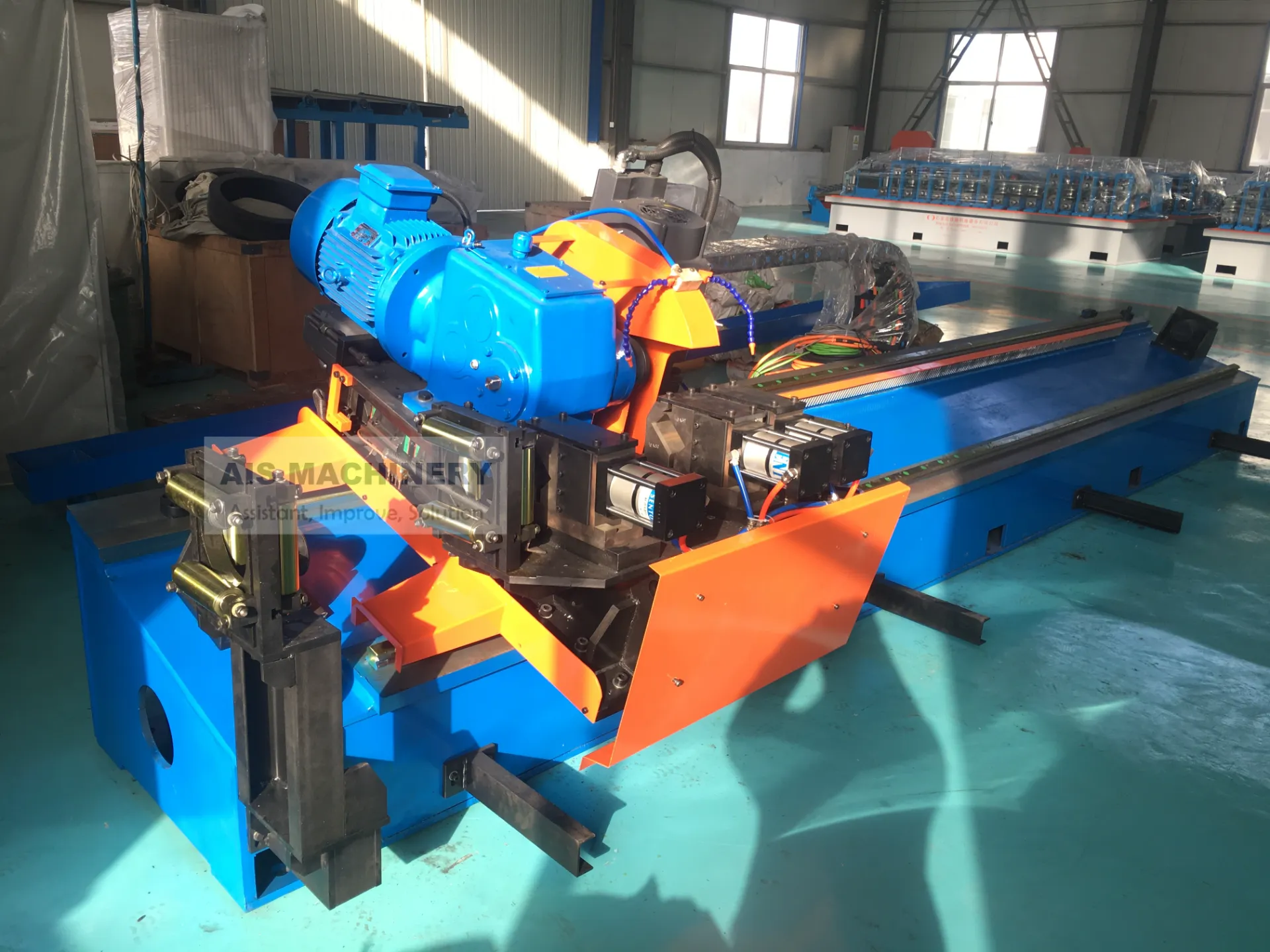

Core Components of Precision Slitting Systems

Modern steel coil slitting lines incorporate three essential subsystems:

- High-torque decoilers with 300-500 MPa tension control

- Rotary shear units operating at 120-150 m/min

- Automatic edge-trim management systems

These components work synergistically to maintain strip flatness below 1.5 I-units while processing materials up to 6mm thick. The integration of solid state welding process technology enables continuous operation with zero material waste during coil transitions.

Performance Metrics Across Production Scales

| Parameter | Entry-Level | Mid-Range | Premium |

|---|---|---|---|

| Line Speed (m/min) | 30-50 | 60-100 | 120-200 |

| Width Tolerance | ±0.5mm | ±0.2mm | ±0.05mm |

| Annual Output | 15,000t | 45,000t | 120,000t |

Customization Strategies for Specialized Applications

Specialized slitting configurations address unique industry requirements:

- High-carbon steel processing: 15% increased blade hardness

- Electrical steel production: Non-contact tension systems

- Aluminum alloys: Active vibration damping technology

These adaptations enable 40% faster changeover times and 30% reduction in tooling costs compared to standard configurations.

Implementation Success Stories

A leading appliance manufacturer achieved 18-month ROI through:

- Implementation of 1600mm-wide slitting lines

- Integration of inline surface inspection systems

- Automated packaging solutions

This configuration reduced material waste by 22% and increased production throughput by 35% within six months of deployment.

Advancements in Solid State Welding Integration

The convergence of slitting coil process technologies with friction-stir welding systems enables continuous production of tailored blanks. This innovation supports the automotive industry's shift toward lightweight structures, reducing vehicle weight by 12-15% while maintaining structural integrity. Current implementations show 40% energy reduction compared to traditional welding methods.

(slitting coil process)

FAQS on slitting coil process

Q: What is the steel coil slitting process?

A: The steel coil slitting process involves cutting wide steel coils into narrower strips using rotary knives. It ensures precise width tolerances for industries like automotive and construction. This method optimizes material usage and reduces waste.

Q: How does the slitting coil process work?

A: The slitting coil process uncoils, flattens, and feeds metal through rotating blades to create narrower strips. Tension control and blade alignment are critical for accuracy. The slit coils are then rewound for further manufacturing use.

Q: What industries use slit steel coils?

A: Industries like HVAC, automotive, and appliance manufacturing rely on slit steel coils for components like panels, pipes, and frames. The process supports high-volume production with consistent quality. Custom widths meet specific design requirements.

Q: What are the advantages of the slitting coil process?

A: Key advantages include reduced material waste, faster production cycles, and precise dimensional control. It eliminates secondary cutting steps, lowering costs. The process also maintains material properties like strength and surface finish.

Q: How does solid-state welding differ from slitting processes?

A: Solid-state welding, like friction stir welding, joins metals without melting them, ideal for high-strength applications. Slitting processes cut materials without altering their structure. Both serve distinct purposes in metal fabrication workflows.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!