-

Tél. : 86-15176910262

Tél. : 86-15176910262

-

Recherche

Efficient Steel Slitting Lines: Revolutionizing Metal Processing

Mai . 08, 2025 15:56

In the world of metal processing, steel slitting lines are integral to efficiently cutting large coils into narrow strips. This process is crucial in industries ranging from automotive manufacturing to construction and home appliances. The demand for high-quality, precise, and efficient cutting has led to the widespread adoption of advanced technologies like steel coil slitting lines and coil slitting machines. In this article, we will explore the capabilities of ss slitting production lines, discuss the benefits they offer, and delve into how businesses can leverage these machines to optimize their operations.

Steel Slitting Lines for Sale: Meeting Industry Demands

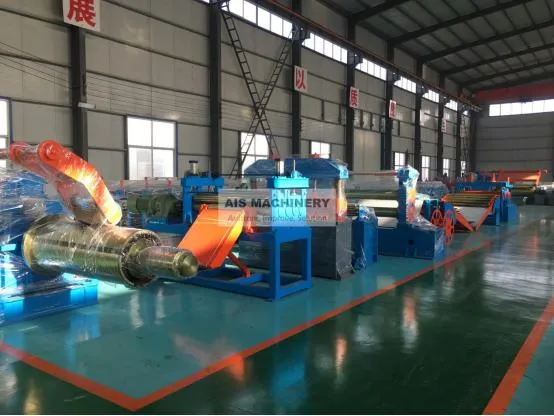

Steel slitting lines for sale represent a vital component for companies involved in metal processing. These machines are specifically designed to slit wide metal coils into narrower strips, with precision and efficiency. A steel slitting line typically includes an uncoiler, slitter, and rewinder, working in tandem to ensure that the slitting process is continuous and accurate. Whether you're processing carbon steel, stainless steel, or galvanized sheet, steel slitting lines are built to handle a variety of materials and thicknesses.

The demand for steel slitting lines has been on the rise due to the rapid growth of industries such as construction, automotive, and home appliances. For instance, the automobile industry requires metal strips for various components, and the construction sector needs slitted metal for structural frameworks. By investing in lignes de refendage d'acier à vendre, companies can streamline their production processes, reduce waste, and improve overall efficiency.

These machines are also highly customizable, making it possible for businesses to tailor their equipment to meet specific needs. For example, a steel coil slitting line may come equipped with advanced features such as automatic tension control and high-precision cutting systems, ensuring that each strip is cut to the required size with minimal deviation. The result is not only a high-quality product but also enhanced production speed and reliability.

Steel Coil Slitting Line Manufacturer: Quality and Precision

When selecting a steel coil slitting line manufacturer, businesses must prioritize quality and precision. The right manufacturer will offer machines that are capable of processing a variety of steel types, including stainless steel, galvanized sheets, and carbon steel. Additionally, a reputable manufacturer ensures that the equipment operates smoothly and efficiently, minimizing downtime and maximizing output.

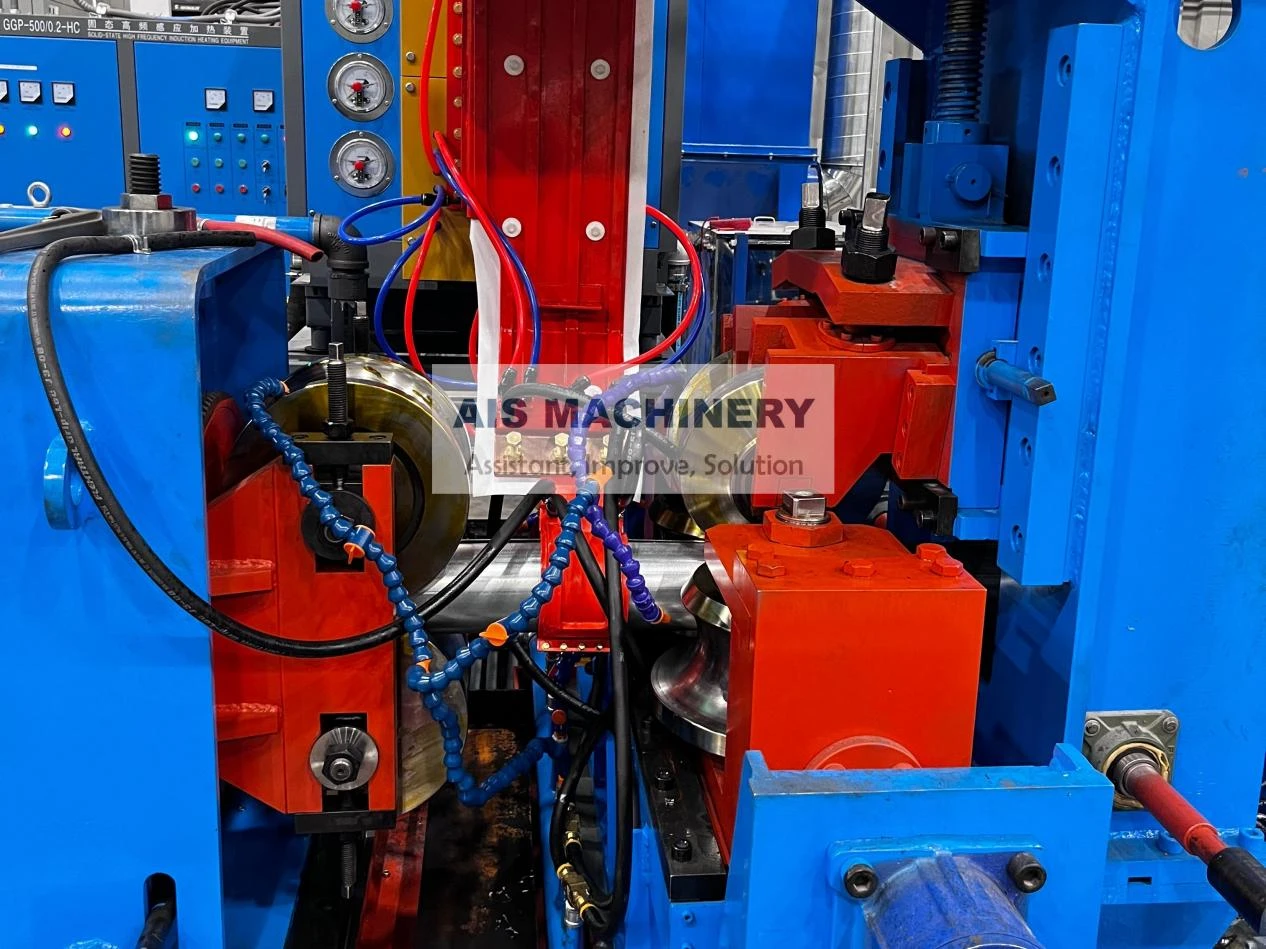

A well-designed steel coil slitting line comes equipped with several advanced features, including automatic tension control systems and high-precision circular knife shafts. These features ensure that each steel coil is slit into strips with clean, sharp edges, maintaining consistency throughout the production process. Furthermore, the automation of the system helps reduce human error, providing more reliable results and improving overall productivity.

Working with a trusted steel coil slitting line manufacturer guarantees that companies will receive equipment designed to meet international standards of safety and performance. These machines often come with certifications such as ISO, CE, and SGS, ensuring that they meet the highest quality and safety requirements. The manufacturer should also provide robust after-sales support, including installation, maintenance, and technical assistance, ensuring that businesses can maintain optimal performance.

Coil Slitting Machine: Enhancing Production Efficiency

The coil slitting machine is the heart of any slitting line, providing the cutting mechanism that transforms large steel coils into narrow strips. A coil slitting machine uses high-speed rotary cutters to precisely cut the steel coil, creating strips with minimal material waste. This is a critical factor in industries that require large quantities of metal products, as it maximizes the use of raw materials.

Coil slitting machines are designed for ease of use and high efficiency. With features such as automatic tension control, PLC control systems, and integrated guiding mechanisms, these machines provide operators with greater control over the slitting process. This technology ensures that the slitting process is consistent, even with variations in material thickness or coil width.

For manufacturers, investing in a high-quality coil slitting machine translates to greater production capacity, reduced operational costs, and improved product quality. By increasing the precision and speed of the slitting process, businesses can meet the increasing demands of industries that rely on high-quality metal strips, such as automotive, construction, and home appliance manufacturing.

SS Slitting Production Line: Advanced Features for Precision Cutting

The ss slitting production line is specially designed for processing stainless steel, offering the necessary tools to handle this challenging material with precision. SS slitting production lines typically feature advanced technology that ensures the consistent cutting of stainless steel coils into narrower strips without compromising the material's integrity.

Stainless steel is widely used in industries where corrosion resistance and durability are paramount, such as in the production of kitchen equipment, medical instruments, and construction materials. SS slitting production lines are equipped with features such as high-precision cutting heads and automatic coil feeding systems to ensure accurate and clean slitting, even for stainless steel’s tough surface.

The ss slitting production line is highly efficient, reducing downtime and improving the overall throughput of production. This efficiency is achieved through automation and precision engineering, which eliminate human error and speed up the production process. Whether you're producing stainless steel strips for industrial or commercial applications, investing in a high-quality ss slitting production line ensures that you’ll meet the rigorous standards required by the market.

Welded Pipe Production Line: Connecting Industries Through Slitting

In addition to steel slitting, a welded pipe production line plays an important role in the processing of steel coils into tubes. The production of welded pipes is closely linked to the slitting process because slitted steel strips are often used as raw material for tube manufacturing. By feeding the slitted strips into a tube mill, manufacturers can produce a wide range of pipes used in industries like construction, oil and gas, and automotive.

The welded pipe production line is designed to efficiently transform slitted coils into high-quality pipes. The process includes forming, welding, and sizing the pipe to meet specific standards. Steel slitting lines provide the precision required to create uniform strips, which are then fed into the tube mill for welding. This synergy between the two processes ensures that manufacturers can produce pipes at a high rate with consistent quality.

By incorporating steel slitting lines into the production process, businesses can enhance their capacity to meet the growing demand for welded pipes. Additionally, this streamlined approach allows manufacturers to reduce lead times and improve overall efficiency, making it an essential part of modern industrial production.

Steel Slitting Lines FAQs

What is a steel slitting line?

A steel slitting line is a machine designed to slit wide metal coils into narrower strips with high precision. It typically consists of an uncoiler, slitter, and rewinder, ensuring continuous processing and high-quality results.

What materials can be processed by a coil slitting machine?

A coil slitting machine can process various materials, including carbon steel, stainless steel, and galvanized sheets, with the ability to handle different thicknesses ranging from 0.25mm to 20mm.

How does a steel coil slitting line work?

A steel coil slitting line uncoils the steel, feeds it through precision slitting rollers, and then rewinds the slitted strips into coils, all while maintaining high accuracy and ensuring clean, sharp edges.

What is the role of a steel slitting line in pipe manufacturing?V

In pipe manufacturing, steel slitting lines provide the raw material in the form of slitted strips, which are then processed into welded pipes. The precision of the slitting process ensures high-quality tubes in the final product.

Where can I buy a steel slitting line?

You can purchase steel slitting lines from reputable manufacturers who specialize in metal processing equipment. Many suppliers offer customizable options to meet your specific production needs, with robust after-sales support and maintenance services.

In conclusion, steel slitting lines are indispensable in the modern manufacturing process, enabling companies to produce high-quality metal strips with efficiency and precision. Whether you need a steel coil slitting line, a coil slitting machine, or an ss slitting production line, investing in the right equipment can significantly boost your production capabilities. Visit our website today to explore our range of lignes de refendage d'acier à vendre, and take the first step toward optimizing your manufacturing process!

Produits connexes

Nouvelles connexes

Envoyer un message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!