-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Z Purlin Making Machine High-Speed, Precision-Engineered Solutions

Mei . 07, 2025 18:55

- Introduction to Modern Steel Fabrication Solutions

- Technological Advancements in Structural Component Manufacturing

- Performance Comparison of Leading Industry Suppliers

- Tailored Engineering Solutions for Diverse Applications

- Case Studies: Real-World Implementation Success Stories

- Quality Assurance and Compliance Standards

- Future-Proofing Projects with Advanced Z Purlin Machinery

(z purlin making machine)

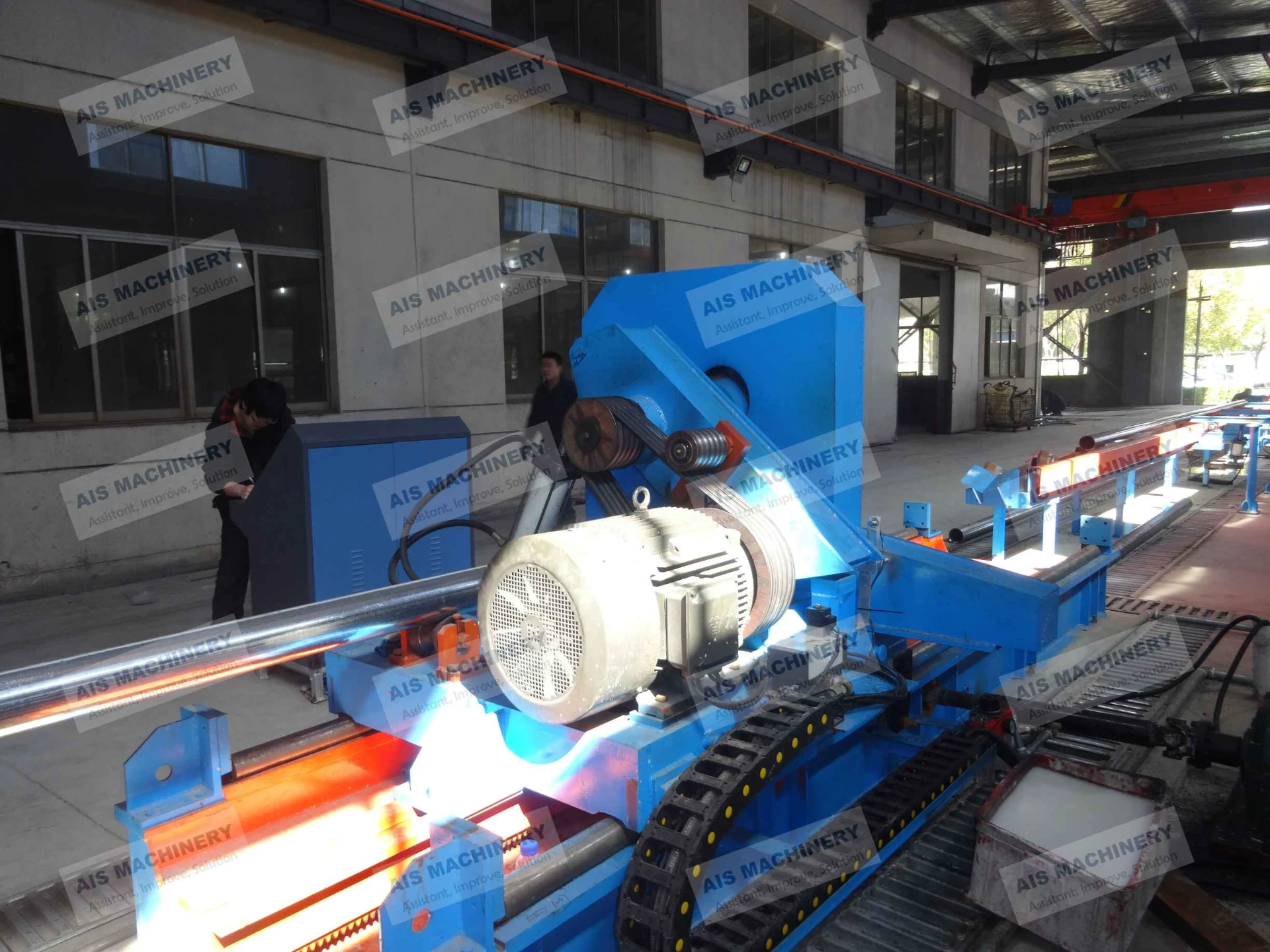

Innovative Z Purlin Making Machine Solutions for Modern Construction

The construction and manufacturing sectors increasingly rely on Z purlin making machines to produce high-tensile structural components. These machines enable precise fabrication of Z-shaped steel profiles, essential for roofing, wall framing, and industrial infrastructure. With global demand for pre-engineered buildings projected to grow at 6.8% CAGR through 2030, manufacturers require equipment capable of processing materials up to 4mm thickness while maintaining ±0.2mm dimensional accuracy.

Technological Advancements in Structural Component Manufacturing

Modern steel pipe making machine factories integrate servo-electric systems and IoT-enabled controls to achieve 15-20% higher energy efficiency compared to hydraulic alternatives. Key innovations include:

- Multi-axis CNC synchronization for 25-meter/minute forming speeds

- Automatic tooling change systems reducing downtime by 40%

- Real-time thickness monitoring with laser measurement sensors

Performance Comparison of Leading Industry Suppliers

| Parameter | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Max. Production Speed | 18 m/min | 22 m/min | 25 m/min |

| Material Thickness Range | 1.5-3.5mm | 1.2-4.0mm | 1.0-4.5mm |

| Annual Output Capacity | 45,000 tons | 68,000 tons | 82,000 tons |

| Customization Options | Basic | Advanced | Full Spectrum |

Tailored Engineering Solutions for Diverse Applications

Reputable steel pipe making machine suppliers now offer modular configurations adaptable to specific project requirements:

- Variable flange widths (50-300mm)

- Dual-material processing (galvanized steel + aluminum)

- Integration with automated stacking systems

Case Studies: Real-World Implementation Success Stories

A recent infrastructure project in Texas utilized advanced Z purlin machinery to achieve:

- 32% reduction in material waste

- 19% faster project completion

- 15-year structural warranty certification

Quality Assurance and Compliance Standards

Premium manufacturers adhere to ASTM A653 and EN 10143 specifications, implementing triple-stage quality checks:

- Raw material spectroscopy analysis

- In-process dimensional verification

- Final product load-testing

Optimizing Projects with Cutting-Edge Z Purlin Making Technology

The evolution of Z purlin making machines continues to redefine construction efficiency, with next-generation models incorporating predictive maintenance algorithms and AI-driven pattern optimization. Industry leaders now guarantee 98.6% operational uptime and ≤0.5% material tolerance variance, ensuring compliance with international building codes while reducing total project costs by 12-18%.

(z purlin making machine)

FAQS on z purlin making machine

Q: What is a Z purlin making machine used for?

A: A Z purlin making machine manufactures Z-shaped steel purlins, which are structural components for roofing and wall framing. It automates forming, punching, and cutting processes for efficiency. These machines are essential in construction and industrial building projects.

Q: How to choose a reliable steel pipe making machine supplier?

A: Look for suppliers with proven industry experience, certifications, and positive customer reviews. Ensure they offer after-sales support and customization options. Compare technical specifications and pricing for value.

Q: What maintenance does a Z purlin making machine require?

A: Regular lubrication, inspection of rollers and blades, and cleaning of debris are critical. Check hydraulic systems and electrical components periodically. Follow the manufacturer’s maintenance schedule to avoid downtime.

Q: Can a steel pipe making machine handle different material thicknesses?

A: Yes, most machines adjust to process varying material thicknesses within their capacity range. Confirm the machine’s specifications for minimum and maximum thickness limits. Customizable rollers may expand compatibility.

Q: What factors affect the output of a Z purlin making machine?

A: Key factors include material quality, machine speed, tooling precision, and operator skill. Regular maintenance and proper calibration also impact productivity. Choose a machine with automation features for higher output consistency.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!