-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Tube Mill for Sale: Premium Welded & ERW Tube Mills

Ago . 09, 2025 06:00

In the intricate world of modern manufacturing, the demand for high-quality pipes and tubes is relentless. From construction and automotive to oil & gas and agriculture, these essential components form the backbone of countless industries. At the heart of their production lies the tube mill for sale, a sophisticated piece of machinery engineered to transform raw steel strips into precise, durable tubular products. This guide dives deep into the universe of tube mills, focusing on the highly efficient Electric Resistance Welded (ERW) technology, its applications, technical intricacies, and what discerning buyers should look for when searching for a reliable tube mill for sale.

Industry Trends and the Evolution of Tube Manufacturing

The global tube and pipe manufacturing market is experiencing significant growth, driven by burgeoning infrastructure development, increased energy demands, and advancements in material science. According to a report by Grand View Research, the global steel pipe and tube market size was valued at USD 235.61 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This upward trajectory underscores the continuous need for advanced tube mill machine solutions. Key trends influencing the market include:

- Automation and Smart Manufacturing: Integration of IoT, AI, and machine learning for predictive maintenance, process optimization, and enhanced efficiency. Modern erw tube mill china are often equipped with advanced PLC controls and HMI (Human Machine Interface) systems.

- Sustainability and Energy Efficiency: Growing emphasis on mills that consume less energy, reduce waste, and incorporate eco-friendly manufacturing processes. High-frequency welding in ERW mills, for example, is more energy-efficient than traditional methods.

- High-Strength Materials: Demand for mills capable of processing advanced high-strength steels (AHSS) and other specialized alloys to meet stringent industry standards and application requirements.

- Customization and Flexibility: Manufacturers are increasingly seeking welded tube mill solutions that offer greater flexibility in producing a wide range of sizes, shapes, and wall thicknesses to cater to diverse customer needs.

Introducing the 2inch 50.8mm ERW Pipe Mill: Precision and Performance

Our featured product, the 2inch 50.8mm ERW Pipe Mill, is a prime example of cutting-edge technology designed to meet the rigorous demands of modern pipe production. This particular tube mill is engineered for precision and high-volume output of pipes with an outside diameter of 50.8mm (2 inches), making it ideal for a variety of applications requiring exact specifications.

Product Name: 2inch 50.8mm ERW Pipe Mill

Product URL: https://www.aistubemill.com/china-erw-50-8mm-tube-mill-factory-and-manufacturers.html

Detailed Process Flow of the ERW Tube Mill

The manufacturing of ERW (Electric Resistance Welded) pipes on a tube mill for sale is a highly synchronized and continuous process. It begins with raw material (steel coil) and culminates in finished pipes, undergoing a series of precise operations. Here’s a breakdown of the typical manufacturing process, highlighting key stages and technologies:

- Coil Loading & Uncoiling: The process begins by loading a large steel coil onto an uncoiler. This machine holds the coil and allows the strip to unwind smoothly and continuously.

- Strip Accumulation (Optional but Common): For continuous operation, an accumulator (e.g., horizontal or vertical spiral accumulator, or a turret head accumulator) stores a buffer of steel strip. This allows the mill to continue running even during the time it takes to weld a new coil end to the previous one (strip joining).

- Leveling & Shearing: The uncoiled strip passes through a leveling machine to remove any curvature or deformities, ensuring a flat profile. A shear then trims the edges of the strip to prepare it for precise forming.

- Forming Section: This is a critical stage where the flat steel strip is progressively shaped into a tubular form.

- Breakdown Pass (BD): Gradually bends the edges of the strip upwards.

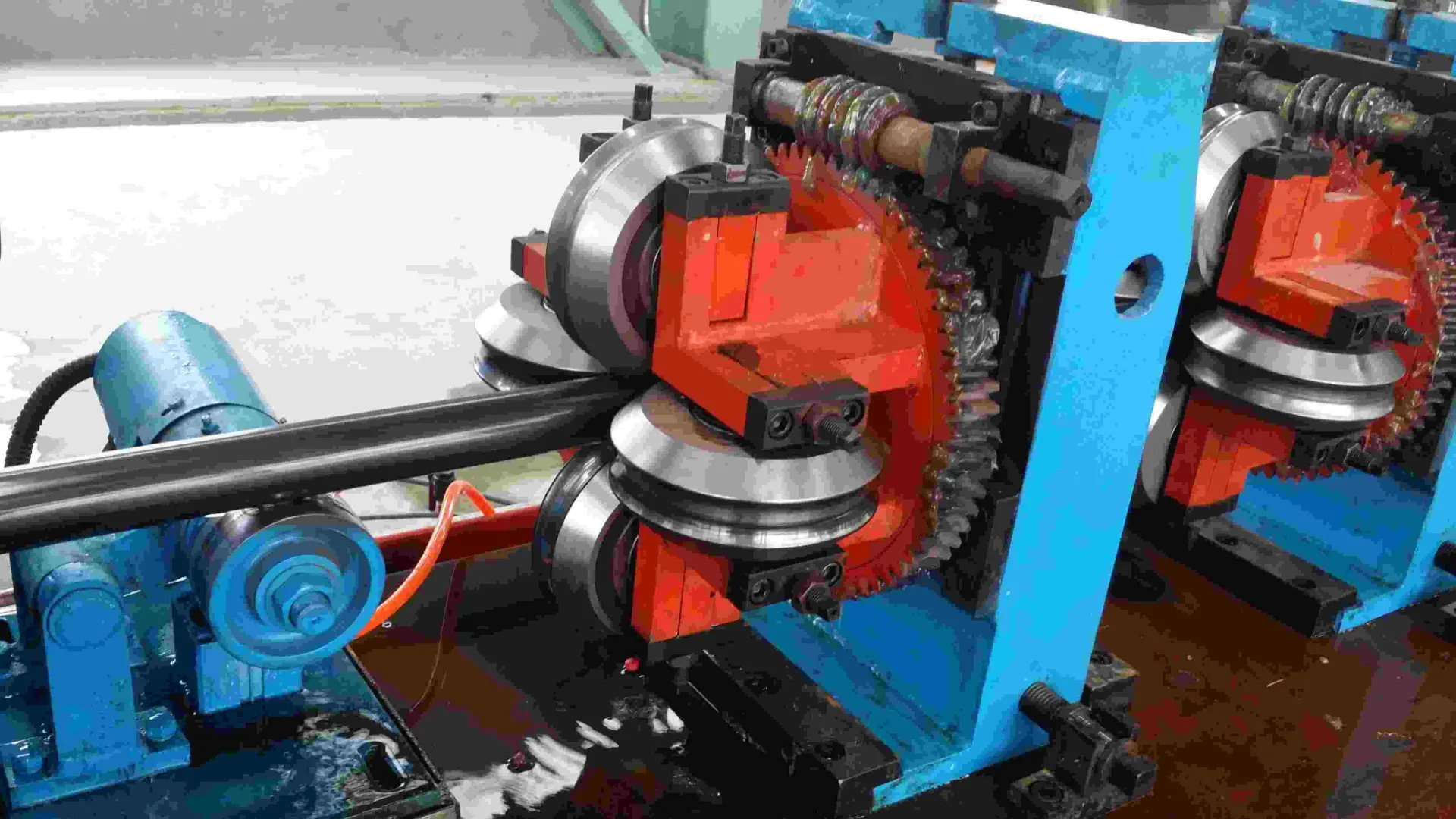

- Fin Pass (FP): Continues to round the strip, bringing the edges closer together to form an open seam tube. Precision rollers, often made via CNC machining for exact profiles, are crucial here.

- Seam Guide: Guides the open seam precisely into the welding section.

- High-Frequency (HF) Welding Section: The core of the ERW process. High-frequency current is passed through the edges of the open tube, generating intense heat. The heated edges are then pressed together by squeeze rolls, forging a solid, strong weld without the need for filler material. This ensures a clean, strong bond. The metallurgy involved here transforms the steel, often requiring specialized steel grades for optimal welding.

- External Weld Bead Scarfing: Immediately after welding, an external cutting tool (scarfer) removes the excess metal (weld bead) that forms on the outer surface of the pipe, ensuring a smooth, uniform exterior.

- Cooling: The newly welded tube passes through a cooling section, typically a water-spray system, to rapidly cool the pipe and stabilize its metallurgical structure.

- Sizing Section: Post-cooling, the pipe enters the sizing section. Here, a series of rollers precisely size the pipe to its final specified outer diameter and roundness. This section also helps in correcting any minor deformities and improving the straightness of the pipe.

- Straightening: Further straightening may occur using a Turks head or roller straightener to ensure the pipe meets specific straightness tolerances.

- Flying Cut-off Saw: A synchronized flying saw cuts the continuous pipe into predetermined lengths. The "flying" aspect means the saw moves along with the pipe as it cuts, ensuring continuous production without stopping the main mill line.

- End Facing & Chamfering (Optional): For certain applications, the pipe ends may be faced (machined flat) and chamfered (beveled) to prepare them for welding to other components.

- Inspection & Testing: Throughout and after the process, various quality control checks are performed:

- Non-Destructive Testing (NDT): Techniques like Eddy Current Testing or Ultrasonic Testing are commonly used to inspect the weld seam for any internal defects or discontinuities. This is a critical quality control step, ensuring compliance with standards like ASTM A53, API 5L, or ISO 3183.

- Hydrostatic Testing: Pipes may be subjected to high internal water pressure to check for leaks or structural integrity.

- Dimensional Checks: Regular measurements of OD, wall thickness, length, and straightness.

- Bundling & Packaging: Finally, the finished pipes are bundled, weighed, and prepared for shipping.

The manufacturing process relies on robust machinery where components are often made through precise CNC machining and robust forging processes, ensuring high durability and accuracy. Materials used for critical components include hardened tool steel, chrome-plated rollers, and wear-resistant alloys, guaranteeing a long service life and consistent product quality.

Key Specifications of the 2inch 50.8mm ERW Pipe Mill

This specific erw tube mill china is designed to produce 2-inch (50.8mm) pipes with exceptional precision. Below are general specifications for a high-performance ERW tube mill of this caliber. Actual parameters may vary slightly based on specific configuration and customization.

Tube Mill for Sale: 2inch 50.8mm ERW Pipe Mill Key Parameters

| Parameter | Value/Description | Unit |

|---|---|---|

| Pipe Outer Diameter (OD) Range | 12.7 - 50.8 (1/2" - 2") | mm (inch) |

| Wall Thickness (WT) Range | 0.5 - 2.5 | mm |

| Tube Material | Carbon Steel (e.g., Q195, Q235, SS304) | - |

| Production Speed (Max.) | 80 - 120 | m/min |

| Welding Method | High-Frequency Induction Welding (HF) | - |

| Installed Power (Total) | ~150 - 250 | kW |

| Tolerance on OD | ±0.05 | mm |

| Tolerance on Wall Thickness | ±0.05 (Based on strip accuracy) | mm |

| Straightness | ≤ 1.0 mm/m | - |

| Main Drive Motor Power | 55 - 75 | kW |

| HF Welder Power | 80 - 150 | kW |

| Applicable Standards | ASTM A53, API 5L, EN 10219, ISO 3183 | - |

| Manufacturing Process for Key Components | CNC Machining, Forging, Precision Grinding | - |

| Expected Service Life | 20+ years with proper maintenance | Years |

Applications and Advantages in Typical Scenarios

The 2inch 50.8mm ERW Pipe Mill is incredibly versatile, serving a broad spectrum of industries:

- Petrochemical Industry: Used for general fluid conveyance, light structural components, and non-critical piping systems. Its reliability and excellent weld integrity (inspected via NDT, typically Eddy Current or Ultrasonic) make it suitable for various applications where anti-corrosion properties are crucial.

- Metallurgy: Essential for producing structural tubes, support beams, and various components within metallurgical plants.

- Water Supply & Drainage: Ideal for water distribution lines, drainage systems, and irrigation due to its cost-effectiveness, ease of installation, and robust construction. The anti-corrosion treatment available for finished pipes significantly extends their lifespan in these environments.

- Construction: Widely used for scaffolding, handrails, framework, and light structural elements. The consistent quality and precise dimensions ensure easy fabrication and compliance with building codes.

- Automotive & Furniture: Precision tubes are critical for automotive components (exhaust systems, chassis parts) and furniture frames, requiring high strength-to-weight ratios and aesthetic finishes.

- Agriculture: Irrigation pipes, greenhouse structures, and general utility piping.

Technical Advantages:

- Energy Efficiency: High-frequency welding offers superior energy utilization compared to traditional methods, leading to lower operating costs and a reduced carbon footprint. This is a significant factor when evaluating a tube mill for sale.

- High Production Speed: Continuous, automated processes allow for high output volumes, boosting productivity and reducing lead times.

- Superior Weld Quality: The ERW process creates a strong, clean weld seam without filler material, resulting in a joint that is often stronger than the parent material, especially after optional seam annealing.

- Dimensional Accuracy: Advanced forming and sizing sections, coupled with precise CNC-machined rollers, ensure tight tolerances on OD, wall thickness, and straightness.

- Cost-Effectiveness: Lower manufacturing costs per meter compared to seamless pipes, making it an economically viable option for mass production.

- Versatility: Capable of producing pipes from a wide range of steel grades (Q195, Q235, SS304 etc.) and accommodating various surface treatments.

Choosing Your tube mill for sale: Manufacturer Comparison and Customization

When selecting a tube mill for sale, the choice of manufacturer is paramount. It’s not just about the machine itself, but also the after-sales support, spare parts availability, and the manufacturer’s expertise. Here are key considerations when comparing manufacturers:

- Experience and Reputation: Look for manufacturers with a long history and proven track record in designing and building tube mill machines. Check their service years in the industry and client testimonials.

- Technological Innovation: Does the manufacturer invest in R&D? Do they offer the latest advancements in automation, welding technology, and quality control systems?

- Customization Capabilities: A reputable manufacturer should be able to offer tailored solutions. For instance, if you need a specific range of pipe sizes, a particular material processing capability, or integration with existing factory systems, the manufacturer should be able to customize the welded tube mill to your exact requirements. This could involve specialized tooling, different HF welder power, or unique cut-off solutions.

- Quality Control and Certifications: Verify that the manufacturer adheres to international quality standards such as ISO 9001. Enquire about the manufacturing processes for their components (e.g., are rollers forged and CNC machined for precision?).

- After-Sales Support: This is critical. What is their policy on installation, commissioning, training, warranty, and spare parts supply? Do they offer remote diagnostics or on-site technical support?

Manufacturer Comparison Factors for Tube Mill for Sale

| Factor | High-Quality Manufacturer (Example) | Standard Manufacturer (Example) |

|---|---|---|

| R&D Investment | High; continuous innovation in automation, energy efficiency, and material processing. | Moderate; focuses on proven designs, less on cutting-edge. |

| Key Components Manufacturing | In-house CNC machining, precision forging for rollers and critical parts. High-grade alloy steels. | Outsourced components, standard materials, less precise machining. |

| After-Sales Support | Global network, rapid response, remote diagnostics, comprehensive spare parts inventory, on-site training & commissioning by expert engineers. | Regional support, slower response, limited spare parts, basic commissioning. |

| Customization Level | High; tailored solutions for size range, material type, speed, automation level, and integrated lines. | Limited; offers standard models with minor adjustments. |

| Quality Assurance | ISO 9001 certified, strict incoming material inspection, multi-stage in-process QC, final performance testing. Adherence to ASTM, API, EN standards. | Basic QC, may not have international certifications. |

| Client Testimonials/References | Strong portfolio of successful global installations with positive feedback and repeat business. | Fewer public testimonials, mainly local clients. |

| Warranty Period | Typically 18-24 months for major components. | Usually 12 months. |

Customization Solutions

A leading erw tube mill china supplier will work closely with clients to provide a customized solution that perfectly aligns with their production goals. This could include:

- Size Range Adaptability: Designing mills with quick-change tooling or multiple forming sections to handle a broader range of pipe diameters and wall thicknesses.

- Material Versatility: Adjusting welding parameters, roll material, and annealing capabilities to process specific steel grades (e.g., stainless steel, galvanized steel, high-strength low-alloy steel).

- Automation Level: From semi-automatic lines to fully integrated, lights-out operations with robotic handling and advanced PLC control systems.

- Integrated Processing: Adding inline processes such as bright annealing (for stainless steel), galvanizing, punching, grooving, or sophisticated NDT systems (e.g., Ultrasonic Phased Array) directly into the tube mill for sale line.

- Energy Optimization: Implementing advanced power management systems and high-efficiency induction welders to minimize energy consumption.

Application Cases: The Tube Mill for Sale in Action

The versatility and efficiency of ERW tube mills are best demonstrated through their successful application across various industries:

- Major Infrastructure Projects: A leading steel manufacturer acquired a high-capacity welded tube mill to supply pipes for a national water pipeline project, requiring millions of meters of corrosion-resistant tubing. The mill's ability to produce pipes with precise dimensions and consistent weld integrity, verified by continuous Eddy Current Testing, was critical to meeting the project's stringent quality and delivery schedules.

- Automotive Component Manufacturing: A specialized automotive parts supplier invested in a compact, high-speed tube mill machine for producing exhaust system components and seat frames. The mill's precision forming and clean welding allowed them to meet strict automotive industry standards for dimensional accuracy and structural integrity, leading to reduced scrap rates and increased production efficiency.

- Furniture Industry Expansion: A furniture manufacturer expanded their operations by integrating an erw tube mill china to produce their own square and rectangular tubing for furniture frames. This significantly reduced their material costs and allowed for greater flexibility in design and quicker turnaround times for new product lines. The mill's capacity for quick changeovers between different tube sizes was a key advantage.

Enhancing Trustworthiness: FAQ, Delivery, and Warranty

Frequently Asked Questions (FAQ) about Tube Mill for Sale

- What is the primary difference between ERW and Seamless pipes?

ERW (Electric Resistance Welded) pipes are manufactured by cold-forming a steel strip into a tubular shape and then welding the edges longitudinally using electric resistance. Seamless pipes, in contrast, are produced by extruding a solid metal billet over a mandrel, without any welding seam. ERW pipes are generally more cost-effective for smaller diameters and thinner walls, while seamless pipes are preferred for high-pressure, high-temperature applications due to their inherent structural uniformity. - What are the common materials processed by a tube mill machine?

Most tube mill for sale are designed to process various grades of carbon steel (e.g., Q195, Q235, SAE 1008, ASTM A36) and stainless steel (e.g., SS304, SS316, SS201). Specialized mills can also handle galvanized steel, aluminum, and certain alloys. - What is High-Frequency Induction Welding in a welded tube mill?

High-Frequency (HF) Induction Welding is a core technology in ERW mills. It uses a high-frequency alternating current to induce heat in the edges of the open steel strip as it forms into a tube. The localized heat brings the edges to a molten state, and then pressure rollers forge them together, creating a solid, strong weld without the need for filler metal. This method is known for its speed, efficiency, and clean weld. - What inspection standards should an erw tube mill china adhere to?

Reputable manufacturers and their products should comply with international standards such as ASTM (American Society for Testing and Materials) like ASTM A53 for steel pipes, API (American Petroleum Institute) such as API 5L for line pipes, EN (European Standards) like EN 10219 for cold-formed structural hollow sections, and ISO (International Organization for Standardization) standards like ISO 3183. These standards cover material specifications, testing methods, and quality requirements. - What is Non-Destructive Testing (NDT) in the context of tube mill operation?

NDT involves inspecting the pipe, particularly the weld seam, for defects without damaging the pipe itself. Common NDT methods used on ERW tube mills include Eddy Current Testing (detects surface and near-surface flaws) and Ultrasonic Testing (detects internal flaws). These tests are crucial for ensuring the integrity and quality of the weld, especially for pipes used in critical applications. - What is the typical lifespan of a tube mill for sale?

With proper installation, regular maintenance, and the use of quality spare parts, a well-built tube mill for sale can have an operational lifespan of 20 to 30 years or even more. The lifespan of critical components like rollers and welding equipment can vary but are designed for thousands of operational hours and are replaceable. - What kind of installation and training support can I expect when purchasing a tube mill for sale?

A reputable manufacturer will typically send experienced engineers to your site for installation supervision, commissioning, and comprehensive operational and maintenance training for your personnel. This ensures that your team is fully equipped to run the tube mill efficiently and safely from day one.

Delivery Cycle and Warranty Commitment

The delivery cycle for a custom-built tube mill for sale typically ranges from 3 to 6 months, depending on the complexity of the design, level of automation, and current production schedule of the manufacturer. This includes manufacturing, assembly, factory testing, and packaging. Expedited options may be available for urgent requirements.

We stand by the quality and performance of our 2inch 50.8mm ERW Pipe Mill. A standard warranty of 18 months from the date of commissioning or 24 months from the date of shipment (whichever comes first) is provided for all major mechanical and electrical components. This warranty covers manufacturing defects and ensures peace of mind for your investment. Our dedicated customer support team is available for technical assistance, troubleshooting, and spare parts supply throughout the lifespan of the machine.

Conclusion: Investing in a High-Performance Tube Mill for Sale

Acquiring a high-quality tube mill for sale like the 2inch 50.8mm ERW Pipe Mill is a strategic investment that can significantly enhance your manufacturing capabilities, reduce production costs, and open doors to new market opportunities. By understanding the intricate manufacturing process, recognizing the technical advantages of ERW technology, and carefully evaluating manufacturers based on their expertise, experience, authoritativeness, and trustworthiness, you can make an informed decision that will yield long-term benefits.

The pipe and tube industry continues to evolve, demanding greater precision, efficiency, and sustainability. Partnering with a leading erw tube mill china supplier ensures that your production line is equipped with the advanced technology needed to meet these challenges head-on, delivering consistent quality and maximizing your operational throughput.

Further Reading and Resources:

- "The Future of Pipe and Tube Manufacturing" - World Steel Association Technical Brief

- "Advances in High-Frequency Welding Technology for Tube Mills" - TWI Global Technical Article

- "Understanding ERW Pipe Manufacturing and Quality Control" - ASTM International Standards Reference (A53)

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!