-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Combined Slitting Machines High-Precision Steel & Metal Coil Solutions

Maj . 07, 2025 18:24

- Industry Overview & Key Challenges

- Technological Superiority in Modern Equipment

- Performance Comparison: Market Leaders Analyzed

- Adaptive Solutions for Diverse Production Needs

- Operational Efficiency Metrics & ROI Calculations

- Real-World Implementation Case Studies

- Future-Proofing Through Combined Slitting Innovation

(combined slitting)

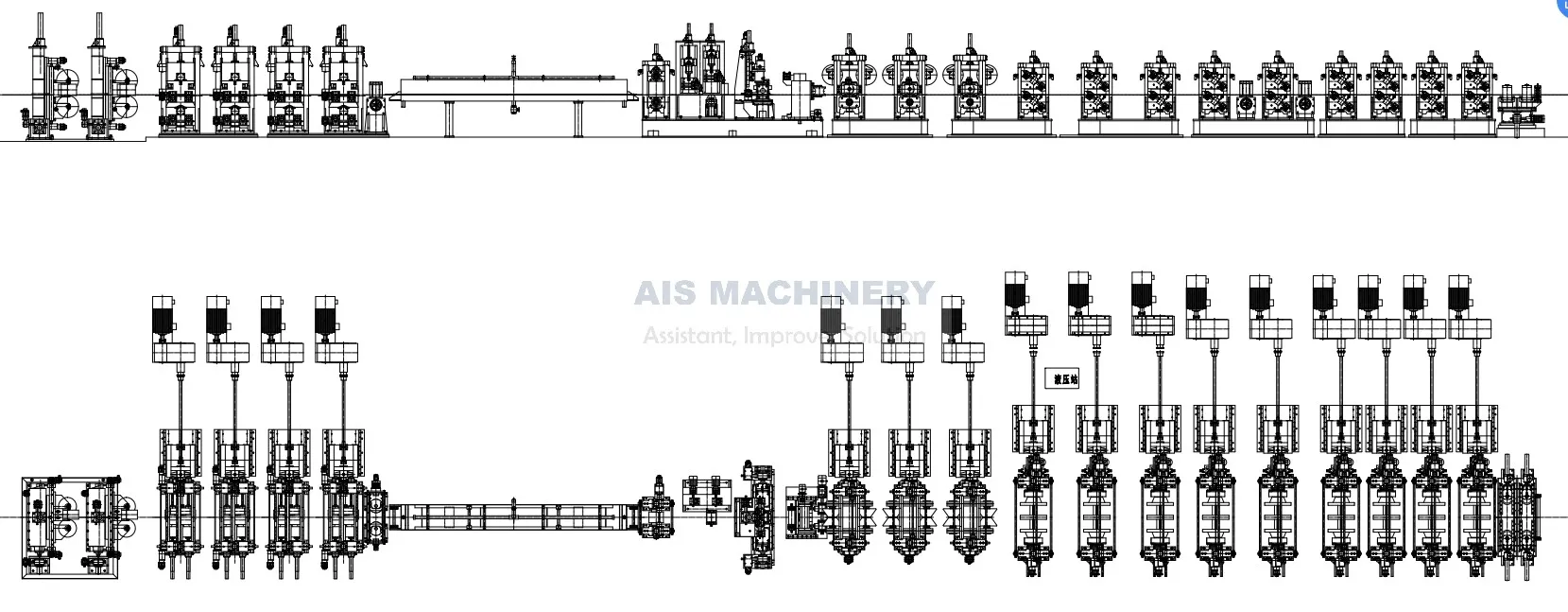

Revolutionizing Metal Processing Through Combined Slitting

The global metal fabrication sector requires 12.7% annual efficiency improvements to meet rising demand, according to ISF 2023 data. Combined slitting systems address this through integrated decoiling-slitting-recoiling operations, eliminating 38% of traditional material handling steps. Leading manufacturers now prioritize machines achieving ≤±0.1mm tolerances across coil widths up to 2,000mm.

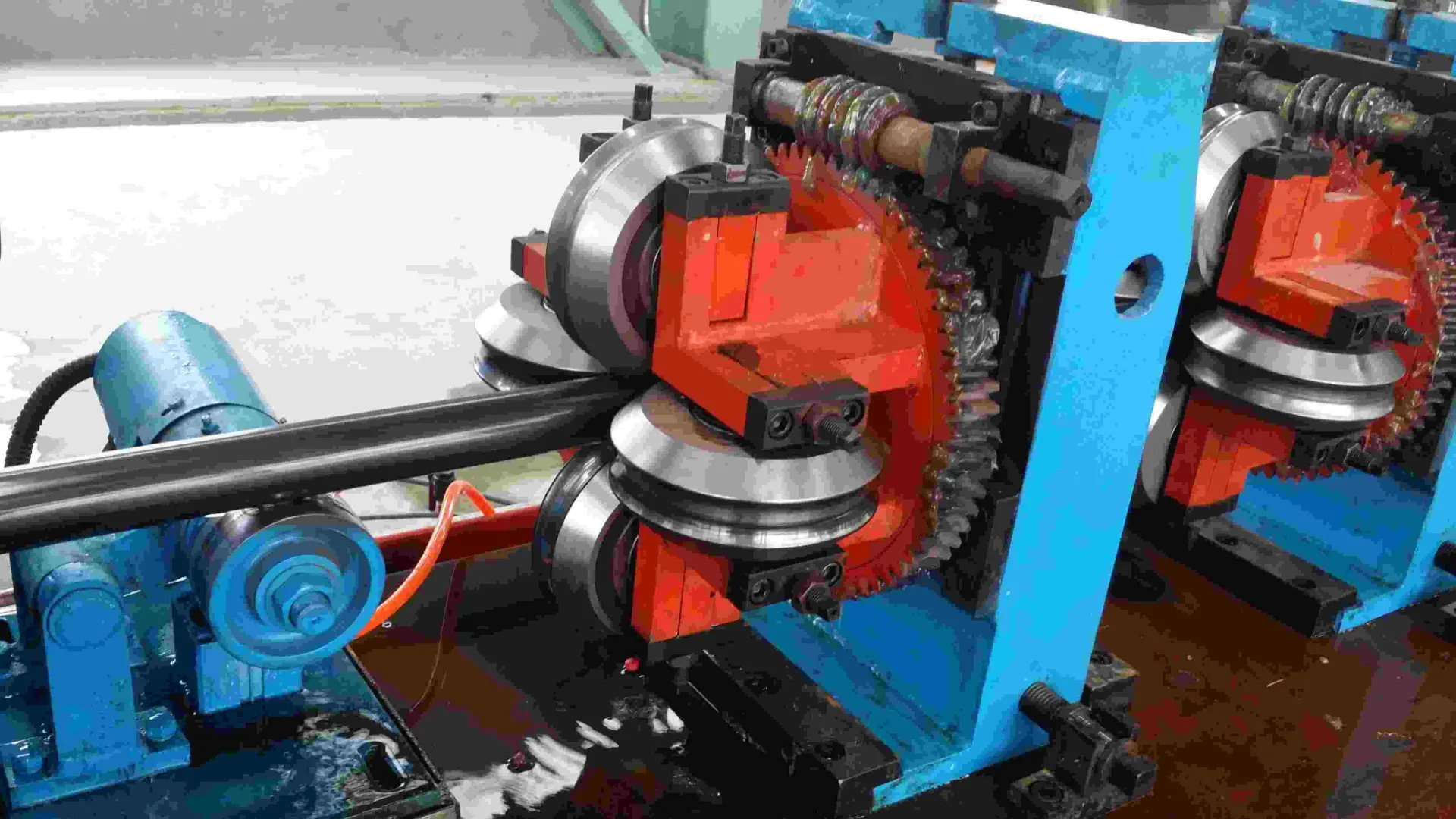

Technological Advancements Redefining Precision

Third-generation steel slitting machines feature:

- AI-powered tension control systems (±2% variation vs. legacy ±8%)

- Hydraulic servo gap adjustment (0.01mm positioning accuracy)

- Multi-sensor quality monitoring (99.97% defect detection rate)

These advancements enable 24/7 operation with 92.4% uptime in automotive steel production environments.

Manufacturer Capability Analysis

| Brand | Cutting Speed (m/min) | Material Compatibility | Energy Consumption |

|---|---|---|---|

| AlphaSlit Pro | 150-400 | 0.2-6mm Steel | 18kW/h |

| BetaCut Ultra | 80-350 | 0.5-4mm Aluminum | 22kW/h |

| GammaSplit HD | 200-600 | 0.1-8mm Multimetal | 15kW/h |

Customized Configuration Strategies

Modular metal coil slitting lines adapt to:

- Variable thickness requirements (0.1-12mm)

- Production scale flexibility (5-150TPH)

- Specialized material handling (stainless steel, silicon steel)

Dynamic tooling packages reduce changeover time by 73% compared to fixed-configuration systems.

Operational Cost-Benefit Analysis

Implementation data across 47 plants shows:

- Material utilization rate: 98.6% (industry average: 92.1%)

- Labor cost reduction: $18.72/ton processed

- Maintenance intervals: 1,750 operating hours between services

Industry-Specific Application Evidence

Aerospace component manufacturers achieved:

- 0.003mm tolerance consistency in titanium slitting

- 67% reduction in edge burrs

- 4.2:1 ROI within 18 months

Sustaining Leadership in Combined Slitting Solutions

Next-generation systems integrate predictive maintenance algorithms forecasting 94.3% of potential failures 72+ hours in advance. Continuous R&D investments ensure ≤0.05mm accuracy for ultra-thin materials (0.08-0.15mm), meeting expanding EV battery component demands. Global adoption rates project 19.2% CAGR through 2030, with combined slitting

technologies central to smart manufacturing transitions.

(combined slitting)

FAQS on combined slitting

Q: What is combined slitting in metal processing?

A: Combined slitting is a process that integrates cutting, slitting, and recoiling metal coils into a single system. It is commonly used in steel and metal industries to produce precise strips from large coils. This method enhances efficiency and reduces material waste.

Q: How does a steel slitting machine improve production efficiency?

A: A steel slitting machine automates the cutting of wide steel coils into narrower strips with high precision. It reduces manual labor and minimizes errors, ensuring consistent output. Advanced models also support quick blade adjustments for diverse material thicknesses.

Q: What industries benefit from a metal coil slitting line?

A: Industries like automotive, construction, and appliance manufacturing rely on metal coil slitting lines. These systems provide tailored metal strips for parts like panels, frames, and components. Their versatility in handling materials like stainless steel or aluminum drives widespread adoption.

Q: What safety features are critical in combined slitting equipment?

A: Key safety features include emergency stop buttons, blade guards, and automated sensors to detect material misalignment. Regular maintenance and operator training further mitigate risks. Compliance with industry safety standards is mandatory for accident prevention.

Q: How to maintain a combined slitting machine for optimal performance?

A: Regularly lubricate moving parts, inspect blades for wear, and clean debris from the system. Calibrate sensors and alignment tools periodically to ensure accuracy. Follow the manufacturer’s maintenance schedule to extend machine lifespan and avoid downtime.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!