-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Tube Mill Production Line - High-Speed Welded Pipe Manufacturing Solutions

พ.ค. . 29, 2025 12:54

- Understanding the Core Mechanics of Tube Mill Production Lines

- Technological Innovations Driving Modern Welded Pipe Production

- Performance Metrics: Speed, Precision, and Energy Efficiency

- Top Tube Mill Line Manufacturers: A Comparative Analysis

- Custom Solutions for Diverse Industrial Requirements

- Case Studies: Successful Applications Across Industries

- Future Trends in Tube Mill Line Optimization

(tube mill production line)

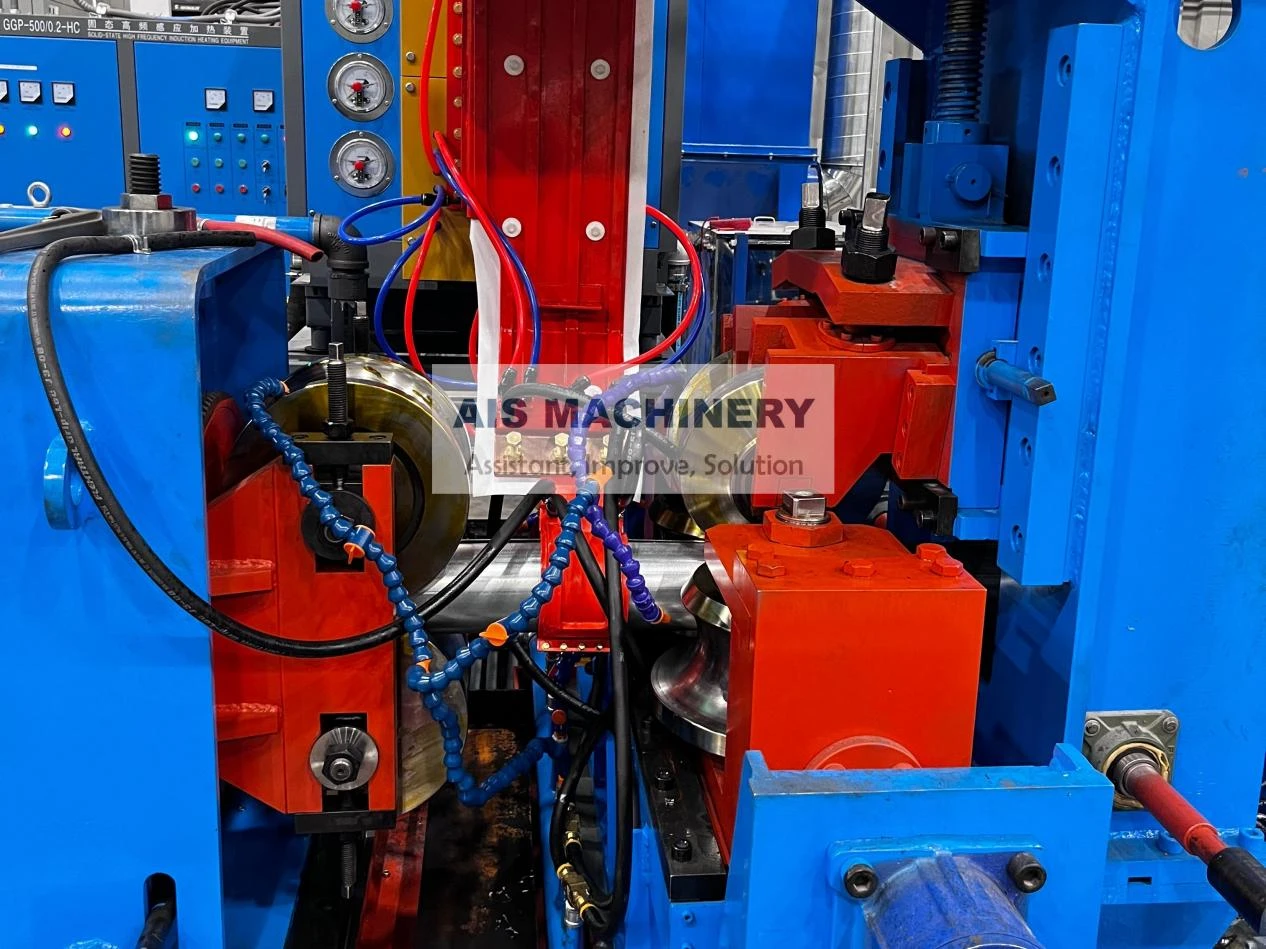

Understanding the Core Mechanics of Tube Mill Production Lines

Tube mill production lines represent the backbone of industrial pipe manufacturing, combining advanced forming, welding, and finishing technologies. Modern systems achieve tolerances as tight as ±0.1mm through laser-guided calibration, ensuring consistent output for critical applications ranging from structural tubing to hydraulic systems. Industry data reveals that automated tube mill lines can produce up to 300 meters of welded pipe per minute, a 40% increase over conventional methods.

Technological Innovations Driving Modern Welded Pipe Production

The integration of AI-powered quality control systems has reduced material waste by 18% in premium tube mill configurations. High-frequency welding (HFW) units now deliver 99.2% seam integrity rates, while inline non-destructive testing (NDT) modules perform real-time thickness verification. These advancements enable production of API 5L-grade pipes with wall thicknesses from 0.4mm to 25.4mm, meeting both ASTM and DIN specifications.

Performance Metrics: Speed, Precision, and Energy Efficiency

Contemporary tube mill lines demonstrate remarkable operational parameters:

| Parameter | Standard Line | High-Speed Line | Heavy-Wall Line |

|---|---|---|---|

| Max Output (m/min) | 120 | 320 | 75 |

| Thickness Range (mm) | 0.4-6.5 | 0.8-4.0 | 6.0-25.4 |

| Power Consumption (kWh/t) | 45 | 38 | 62 |

| OD Accuracy (mm) | ±0.15 | ±0.08 | ±0.25 |

Top Tube Mill Line Manufacturers: A Comparative Analysis

Leading manufacturers differentiate through specialized capabilities:

| Supplier | Key Strength | Typical Lead Time | Service Network |

|---|---|---|---|

| TechPipe Systems | Custom roll tooling | 18 weeks | 32 countries |

| MillMaster Pro | Hybrid drive systems | 14 weeks | 45 countries |

| TubeForm Solutions | Quick-change modules | 12 weeks | 28 countries |

Custom Solutions for Diverse Industrial Requirements

Modular tube mill configurations now enable rapid format changes between round, square, and rectangular profiles within 90-minute setups. Specialized variants include:

- Stainless steel lines with argon-shielded welding chambers

- Coil-fed systems handling 72-ton master coils

- Dual-head mills producing nested pipe sizes simultaneously

Case Studies: Successful Applications Across Industries

A recent automotive project achieved 23% weight reduction in chassis components through precision oval tubing produced on modified mill lines. Energy sector installations demonstrate 15-year durability in offshore environments using cathodic protection-compatible systems. Construction clients report 11% cost savings via integrated punching/notching modules that eliminate secondary processing.

Future Trends in Tube Mill Line Optimization

As global demand for precision tubing grows 6.7% annually, next-generation tube mill production line

s incorporate predictive maintenance algorithms and closed-loop material tracking. Emerging hydrogen pipeline specifications are driving development of 18-meter/minute lines capable of producing 48-inch diameter pipes with 30mm wall thickness. These innovations ensure welded pipe production remains at the forefront of industrial manufacturing technology.

(tube mill production line)

FAQS on tube mill production line

What are the main components of a tube mill production line?

Q: What are the main components of a tube mill production line?

A: A tube mill production line typically includes an uncoiler, forming station, welding unit, sizing section, cutting machine, and finishing equipment. These components work together to shape, weld, and process metal into seamless or welded tubes. Automation systems ensure precision and efficiency.

What industries use welded pipe production lines?

Q: What industries use welded pipe production lines?

A: Welded pipe production lines are widely used in construction, automotive, oil and gas, and HVAC industries. They produce pipes for structural applications, fluid transport, and mechanical systems. Customizable setups cater to specific material and dimensional requirements.

How to choose the right tube mill line for manufacturing?

Q: How to choose the right tube mill line for manufacturing?

A: Consider factors like material type (steel, stainless steel, aluminum), tube diameter, thickness, and production volume. Evaluate the line’s speed, automation level, and compatibility with auxiliary tools. Supplier expertise and after-sales support are also critical.

Why is regular maintenance important for tube mill production lines?

Q: Why is regular maintenance important for tube mill production lines?

A: Regular maintenance prevents wear and tear, ensures consistent product quality, and reduces downtime. It extends the lifespan of rollers, welding heads, and cutting tools. Scheduled checks also optimize energy efficiency and operational safety.

What advancements have improved welded pipe production line efficiency?

Q: What advancements have improved welded pipe production line efficiency?

A: Modern advancements include laser welding, real-time monitoring systems, and AI-driven quality control. High-frequency induction welding and precision forming technologies enhance speed and accuracy. Energy-efficient designs also reduce operational costs.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!