The cage accumulator is a commonly used material storage device in ERW tube mill production lines. It serves as a buffer between the uncoiler, shear and butt welder, and the forming mill, ensuring continuous production without interruption and improving the overall line efficiency.

The steel strip is stored helically around a vertical cage frame, maintaining stable strip tension and allowing quick feeding.

It is suitable for the production of carbon steel, stainless steel, and alloy steel pipes, especially for medium to high-capacity requirements.

1. Application Solutions

-

Standard Solution:

Uncoiler → Shear & Butt Welder → Cage Accumulator → Forming Mill → Welding/Sizing → Flying Saw → Stacking.

-

High-Speed Upgrade:

Integrates with automatic uncoiler, double-head shear and butt welder, and PLC-based speed control for fully automated production lines.

-

Heavy-Duty Solution:

Reinforced cage frame with servo-controlled tension system, suitable for producing high-strength steel strips of thickness 3.0–4.5mm and above.

2. Technical Requirements

-

The cage frame must adopt high-strength welded structure, with shot blasting and anti-corrosion treatment.

-

Key rotating parts shall be equipped with imported bearings to ensure stable and vibration-free operation.

-

Tension control system must respond quickly to avoid strip slack or breakage.

-

Anti-strip-jumping devices must be installed for high-speed running safety.

-

Emergency stop system and protective fencing must meet CE or local safety standards.

-

Maintenance access doors must be provided for easy servicing.

3. Technical Specifications (Customizable)

| Item |

Parameter |

| Applicable Strip Width |

60mm–600mm (customizable) |

| Applicable Strip Thickness |

0.5mm–4.5mm |

| Storage Capacity |

100m–250m (customizable) |

| Floor Space Required |

Approx. L5m × W1m × H4m |

| Max. Strip Speed |

80–120m/min (depends on line design) |

| Cage Frame Material |

High-strength alloy steel |

| Tension Adjustment |

Electric/Pneumatic control |

| Safety Features |

Limit switches, anti-strip-jumping fence, emergency braking |

4. Key Advantages of Cage Accumulator

-

Simple structure, cost-effective: About 20% lower cost compared to disk accumulators.

-

Easy maintenance: Mostly mechanical parts, simple and low-cost servicing.

-

Stable operation: Natural helical storage ensures uniform strip tension, reducing forming defects.

-

Strong adaptability: Suitable for various materials and strip thicknesses.

-

Moderate footprint: Saves about 30% of space compared to traditional horizontal accumulators.

5. Comparison Between Cage Accumulator and Disk Accumulator

Summary:

If ultra-high speed (150m/min and above) is required, a disk accumulator is preferred.

For standard medium-high speed tube mills, a cage accumulator is the optimal choice considering cost and reliability.

6. Cage Accumulator Selection Guide

【Notes on Selection】

-

Strip width and thickness are the basic criteria for selecting the cage accumulator model.

-

Line speed determines whether enhanced tension control and safety features are needed.

-

Factory layout restrictions and surface protection needs should be communicated early for tailored designs.

-

For cost-performance balance, the standard medium-duty cage accumulator is recommended for most ERW production lines.

RELATION EQUIPMENT

We provides all equipment to tube mill entry section:

Coil Car

Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

Peeler and hold down roll arm

Flattening Machine

Automatic and Semi Auto Shearer & Butt Welder

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

OUR SERVICE

Why Choose Us?

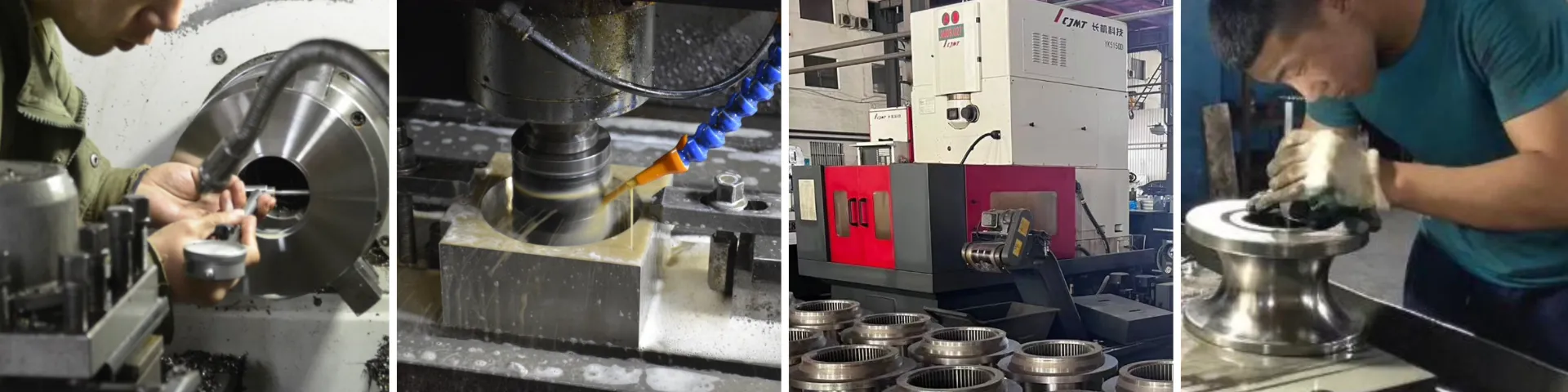

Leading Technology, Reliable Quality, Excellent Service!

Optimized Design, High quality material select!

Heat treatment process guarantee!

Spiral bevel gear, drum gear coupling and carburization.

Gear teeth quenching.

Driven system stable, efficient and wearable with lower noise.

High precision wear resisting and Long life of rollers.

All the machine Lathes, Key Grooves are positioned and Milled by CNC.

After-sales service

1.We will delivery the machine and provide the documents on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions, Our fast and professional aftersales service engineer team will go to your factory to install the machine, give you the operating manual, And train your employee until they can operate the machine well.

3.We provide one year warranty and life-long technical support.

4.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

5 .24 hours for engineer response.

6.Your business relationship with us will be confidential to any third party.

Quality Control

We have the single quality department, that make sure the material of the raw materials is good, and ensure the machine running smoothly.

Tel:86-15176910262

Tel:86-15176910262