The cage accumulator is a commonly used material storage device in ERW tube mill production lines. It serves as a buffer between the uncoiler, shear and butt welder, and the forming mill, ensuring continuous production without interruption and improving the overall line efficiency.

The steel strip is stored helically around a vertical cage frame, maintaining stable strip tension and allowing quick feeding.

It is suitable for the production of carbon steel, stainless steel, and alloy steel pipes, especially for medium to high-capacity requirements.

1. Application Solutions

-

Standard Solution:

Uncoiler → Shear & Butt Welder → Cage Accumulator → Forming Mill → Welding/Sizing → Flying Saw → Stacking.

-

High-Speed Upgrade:

Integrates with automatic uncoiler, double-head shear and butt welder, and PLC-based speed control for fully automated production lines.

-

Heavy-Duty Solution:

Reinforced cage frame with servo-controlled tension system, suitable for producing high-strength steel strips of thickness 3.0–4.5mm and above.

2. Technical Requirements

-

The cage frame must adopt high-strength welded structure, with shot blasting and anti-corrosion treatment.

-

Key rotating parts shall be equipped with imported bearings to ensure stable and vibration-free operation.

-

Tension control system must respond quickly to avoid strip slack or breakage.

-

Anti-strip-jumping devices must be installed for high-speed running safety.

-

Emergency stop system and protective fencing must meet CE or local safety standards.

-

Maintenance access doors must be provided for easy servicing.

3. Technical Specifications (Customizable)

| Item |

Parameter |

| Applicable Strip Width |

60mm–600mm (customizable) |

| Applicable Strip Thickness |

0.5mm–4.5mm |

| Storage Capacity |

100m–250m (customizable) |

| Floor Space Required |

Approx. L5m × W1m × H4m |

| Max. Strip Speed |

80–120m/min (depends on line design) |

| Cage Frame Material |

High-strength alloy steel |

| Tension Adjustment |

Electric/Pneumatic control |

| Safety Features |

Limit switches, anti-strip-jumping fence, emergency braking |

4. Key Advantages of Cage Accumulator

-

Simple structure, cost-effective: About 20% lower cost compared to disk accumulators.

-

Easy maintenance: Mostly mechanical parts, simple and low-cost servicing.

-

Stable operation: Natural helical storage ensures uniform strip tension, reducing forming defects.

-

Strong adaptability: Suitable for various materials and strip thicknesses.

-

Moderate footprint: Saves about 30% of space compared to traditional horizontal accumulators.

5. Comparison Between Cage Accumulator and Disk Accumulator

Summary:

If ultra-high speed (150m/min and above) is required, a disk accumulator is preferred.

For standard medium-high speed tube mills, a cage accumulator is the optimal choice considering cost and reliability.

6. Cage Accumulator Selection Guide

【Notes on Selection】

-

Strip width and thickness are the basic criteria for selecting the cage accumulator model.

-

Hat hızı determines whether enhanced tension control and safety features are needed.

-

Factory layout restrictions and surface protection needs should be communicated early for tailored designs.

-

For cost-performance balance, the standard medium-duty cage accumulator is recommended for most ERW production lines.

İLİŞKİ EKİPMANLARI

Boru değirmen giriş bölümüne tüm ekipmanları sağlıyoruz:

Bobin Arabası

Tek ve Çift Kafa Rulo Açma Makinesi ve Hidrolik ve Pnömatik Rulo Açma Makinesi

Soyucu ve tutma kolu rulosu

Düzleştirme Makinesi

Otomatik ve Yarı Otomatik Kesme ve Kaynak Makinesi

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

HİZMETİMİZ

Neden Bizi Seçmelisiniz?

Lider Teknoloji, Güvenilir Kalite, Mükemmel Hizmet!

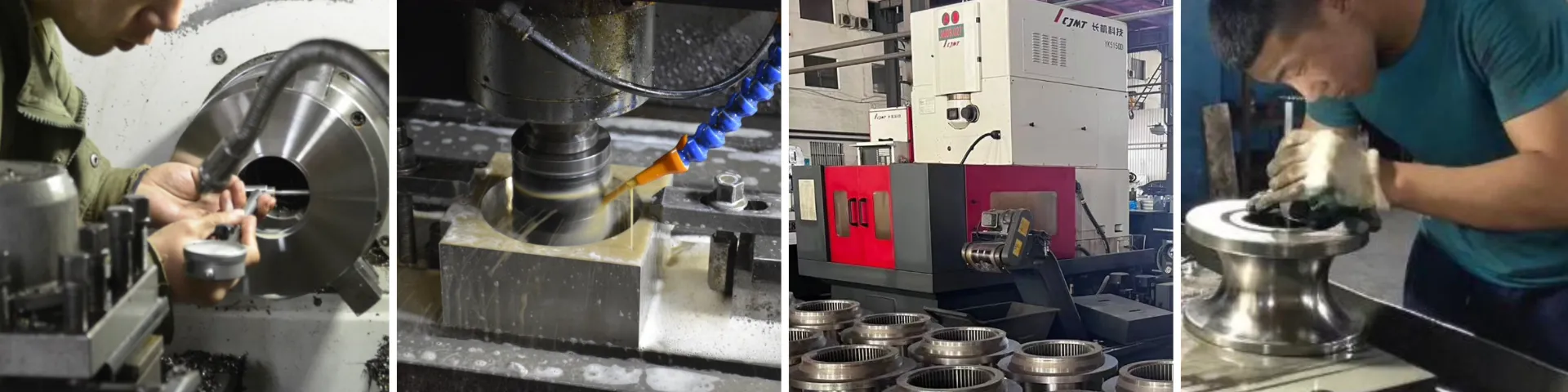

Optimize Edilmiş Tasarım, Yüksek kaliteli malzeme seçimi!

Isıl işlem prosesi garantisi!

Spiral konik dişli, tambur dişli kaplin ve karbürizasyon.

Dişlilerin su verilmesi.

Sürüş sistemi daha az gürültüyle daha stabil, verimli ve giyilebilir hale getirildi.

Yüksek hassasiyetli aşınma direnci ve uzun ömürlü silindirler.

Tüm makine Torna tezgahlarında, Kama Yivleri CNC ile konumlandırılmış ve frezelenmiştir.

Satış sonrası servis

1.Makineyi hızlı bir şekilde alabilmeniz için makineyi zamanında teslim edeceğiz ve belgeleri sağlayacağız.

2. Hazırlık koşullarını tamamladığınızda, hızlı ve profesyonel satış sonrası servis mühendis ekibimiz makineyi kurmak, kullanım kılavuzunu vermek ve çalışanlarınızı makineyi iyi bir şekilde çalıştırabilecekleri zamana kadar eğitmek için fabrikanıza gidecektir.

3.Bir yıl garanti ve ömür boyu teknik destek sağlıyoruz.

4.İyi eğitimli ve deneyimli personelimiz tüm sorularınızı İngilizce ve Çince olarak yanıtlayacaktır.

Mühendisin yanıt vermesi için 5.24 saat.

6.Bizimle olan ticari ilişkiniz üçüncü şahıslarla gizli kalacaktır.

Kalite Kontrol

Hammaddelerin kaliteli olduğundan emin olan ve makinenin sorunsuz çalışmasını sağlayan tek bir kalite departmanımız var.

Tel:86-15176910262

Tel:86-15176910262