The cage accumulator is a commonly used material storage device in ERW tube mill production lines. It serves as a buffer between the uncoiler, shear and butt welder, and the forming mill, ensuring continuous production without interruption and improving the overall line efficiency.

The steel strip is stored helically around a vertical cage frame, maintaining stable strip tension and allowing quick feeding.

It is suitable for the production of carbon steel, stainless steel, and alloy steel pipes, especially for medium to high-capacity requirements.

1. Application Solutions

-

Standard Solution:

Uncoiler → Shear & Butt Welder → Cage Accumulator → Forming Mill → Welding/Sizing → Flying Saw → Stacking.

-

High-Speed Upgrade:

Integrates with automatic uncoiler, double-head shear and butt welder, and PLC-based speed control for fully automated production lines.

-

Heavy-Duty Solution:

Reinforced cage frame with servo-controlled tension system, suitable for producing high-strength steel strips of thickness 3.0–4.5mm and above.

2. Technical Requirements

-

The cage frame must adopt high-strength welded structure, with shot blasting and anti-corrosion treatment.

-

Key rotating parts shall be equipped with imported bearings to ensure stable and vibration-free operation.

-

Tension control system must respond quickly to avoid strip slack or breakage.

-

Anti-strip-jumping devices must be installed for high-speed running safety.

-

Emergency stop system and protective fencing must meet CE or local safety standards.

-

Maintenance access doors must be provided for easy servicing.

3. Technical Specifications (Customizable)

| Item |

Parameter |

| Applicable Strip Width |

60mm–600mm (customizable) |

| Applicable Strip Thickness |

0.5mm–4.5mm |

| Storage Capacity |

100m–250m (customizable) |

| Floor Space Required |

Approx. L5m × W1m × H4m |

| Max. Strip Speed |

80–120m/min (depends on line design) |

| Cage Frame Material |

High-strength alloy steel |

| Tension Adjustment |

Electric/Pneumatic control |

| Safety Features |

Limit switches, anti-strip-jumping fence, emergency braking |

4. Key Advantages of Cage Accumulator

-

Simple structure, cost-effective: About 20% lower cost compared to disk accumulators.

-

Easy maintenance: Mostly mechanical parts, simple and low-cost servicing.

-

Stable operation: Natural helical storage ensures uniform strip tension, reducing forming defects.

-

Strong adaptability: Suitable for various materials and strip thicknesses.

-

Moderate footprint: Saves about 30% of space compared to traditional horizontal accumulators.

5. Comparison Between Cage Accumulator and Disk Accumulator

Summary:

If ultra-high speed (150m/min and above) is required, a disk accumulator is preferred.

For standard medium-high speed tube mills, a cage accumulator is the optimal choice considering cost and reliability.

6. Cage Accumulator Selection Guide

【Notes on Selection】

-

Strip width and thickness are the basic criteria for selecting the cage accumulator model.

-

Line speed determines whether enhanced tension control and safety features are needed.

-

Factory layout restrictions and surface protection needs should be communicated early for tailored designs.

-

For cost-performance balance, the standard medium-duty cage accumulator is recommended for most ERW production lines.

EQUIPEMENT DE RELATION

Nous fournissons tout l'équipement pour la section d'entrée du laminoir à tubes :

Voiture à bobine

Dérouleur à tête simple et double et dérouleur hydraulique et pneumatique

Bras d'éplucheur et de maintien du rouleau

Machine à aplatir

Cisailleuse et soudeuse bout à bout automatique et semi-automatique

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

NOTRE SERVICE

Pourquoi nous choisir?

Technologie de pointe, qualité fiable, excellent service !

Conception optimisée, sélection de matériaux de haute qualité !

Garantie du processus de traitement thermique !

Engrenage conique hélicoïdal, accouplement à tambour et cémentation.

Trempe des dents d'engrenages.

Système d'entraînement stable, efficace et portable avec moins de bruit.

Haute précision, résistance à l'usure et longue durée de vie des rouleaux.

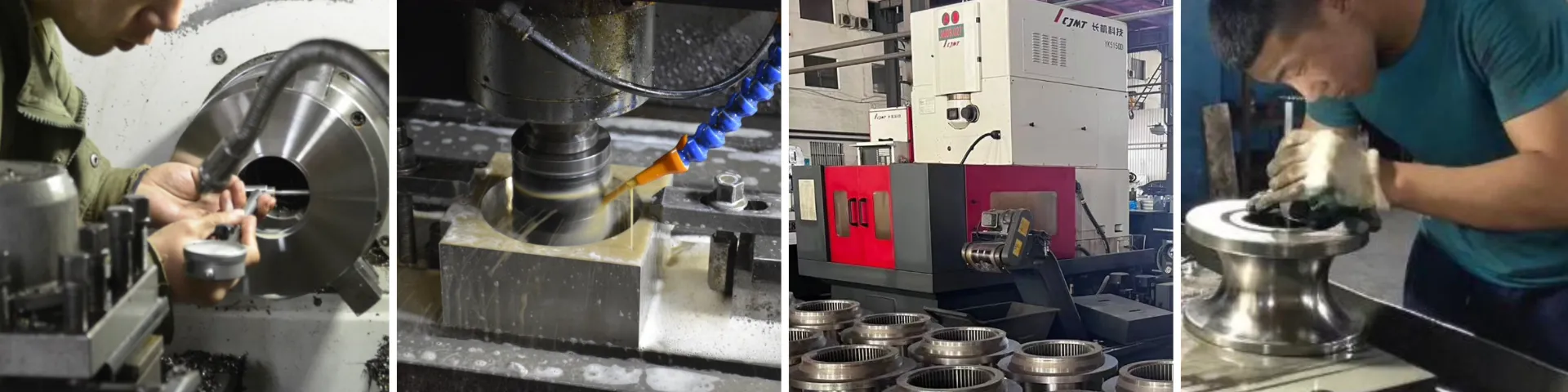

Tous les tours mécaniques, les rainures de clavette sont positionnés et fraisés par CNC.

Service après-vente

1. Nous livrerons la machine et fournirons les documents à temps pour nous assurer que vous pouvez obtenir la machine rapidement

2. Lorsque vous avez terminé les conditions de préparation, notre équipe d'ingénieurs du service après-vente rapide et professionnel se rendra dans votre usine pour installer la machine, vous remettre le manuel d'utilisation et former votre employé jusqu'à ce qu'il puisse bien utiliser la machine.

3. Nous offrons une garantie d'un an et un support technique à vie.

4. Un personnel bien formé et expérimenté répondra à toutes vos demandes en anglais et en chinois

5,24 heures pour l'intervention de l'ingénieur.

6. Votre relation commerciale avec nous sera confidentielle envers tout tiers.

Contrôle de qualité

Nous disposons d'un département de qualité unique, qui garantit que le matériau des matières premières est bon et garantit le bon fonctionnement de la machine.

Tél. : 86-15176910262

Tél. : 86-15176910262