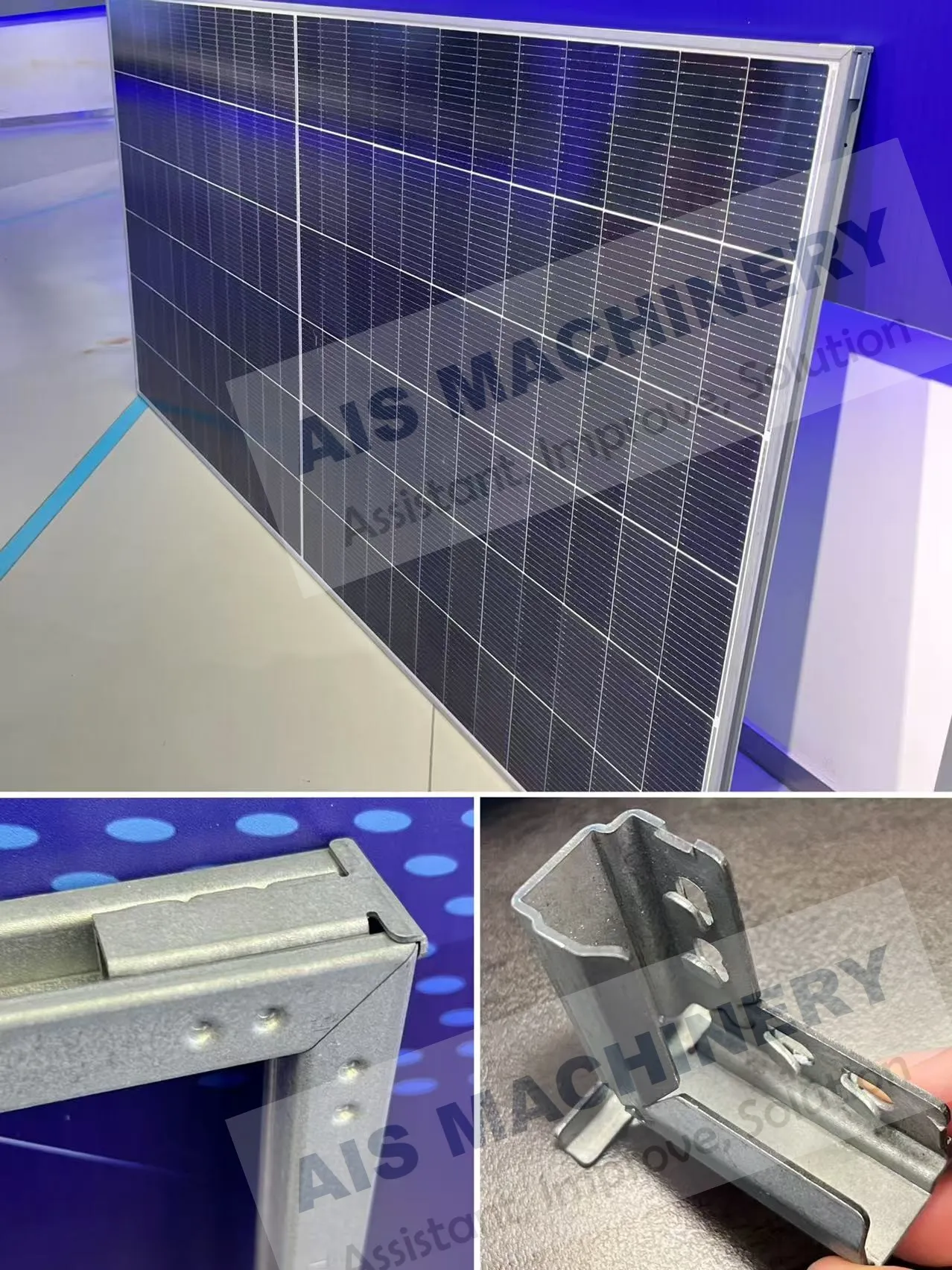

Solar Panel Frame Roll Forming Machine (Carbon Steel Type)

1. Introduction

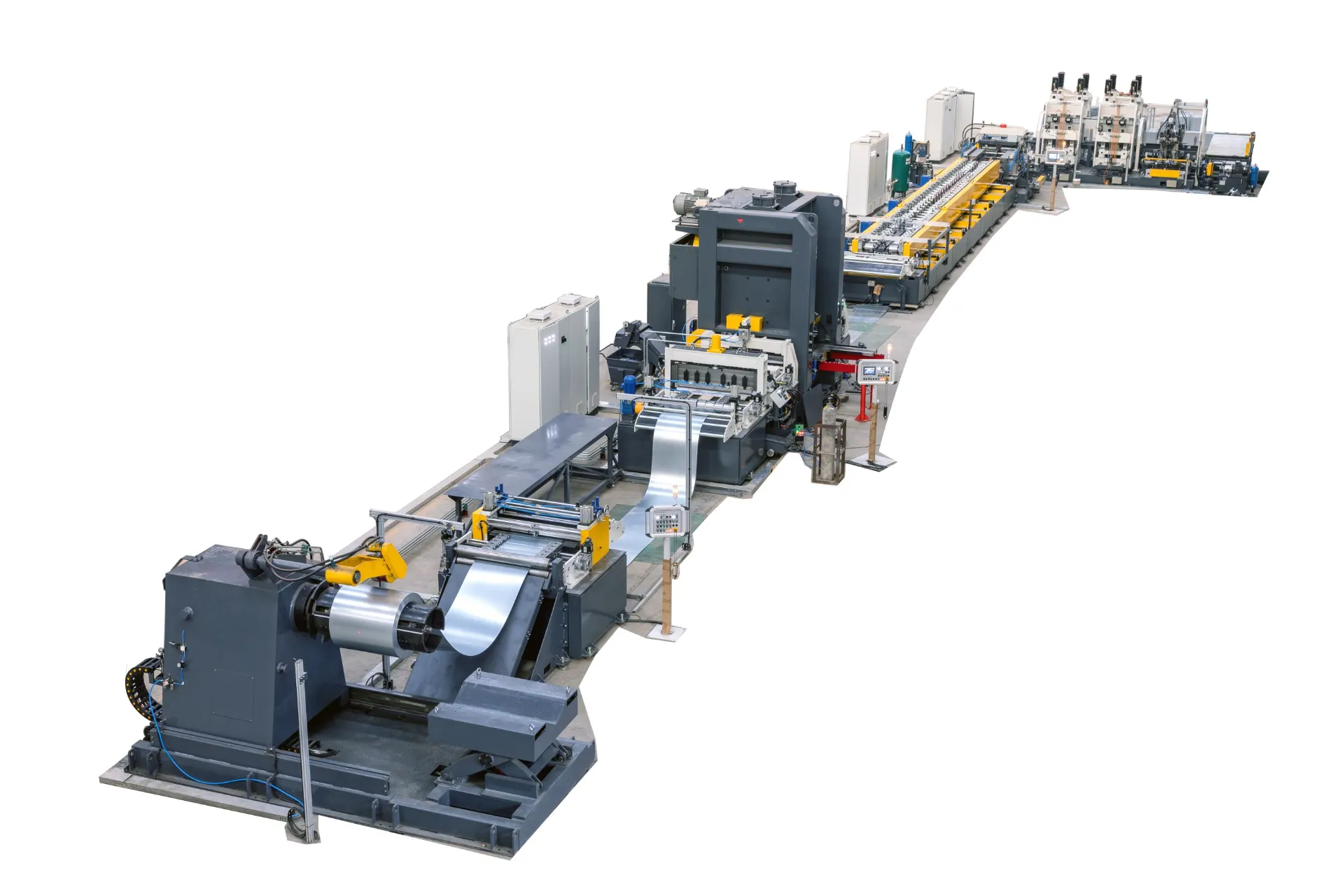

This roll forming line is engineered for manufacturing carbon steel frames used in photovoltaic (PV) solar panels. Designed for stability and efficiency, the machine automates punching, forming, and cutting in a continuous process, allowing for high-precision frame production with minimal material waste.

This model is optimized for long-run production with programmable control and real-time diagnostics.

2. Machine Composition

The system is composed of the following modules:

-

Manual Decoiler or Hydraulic Uncoiler

-

Feeding and Leveling System

-

Precision Servo Punching Station

-

Main Roll Forming Section

-

Servo Flying Shear Cut-Off Unit

-

Runout Table and Optional Auto Stacker

-

Centralized Electrical Control System (PLC + HMI)

3. Technical Data

| Parameter |

Specification |

| Frame Material |

Cold rolled carbon steel, galvanized steel |

| Material Width |

45 – 100 mm |

| Material Thickness |

0.8 – 2.0 mm |

| Production Speed |

Up to 15 meters per minute |

| Forming Stations |

14 – 20 steps (customizable) |

| Cutting Tolerance |

±0.3 mm |

| Punching Accuracy |

±0.5 mm |

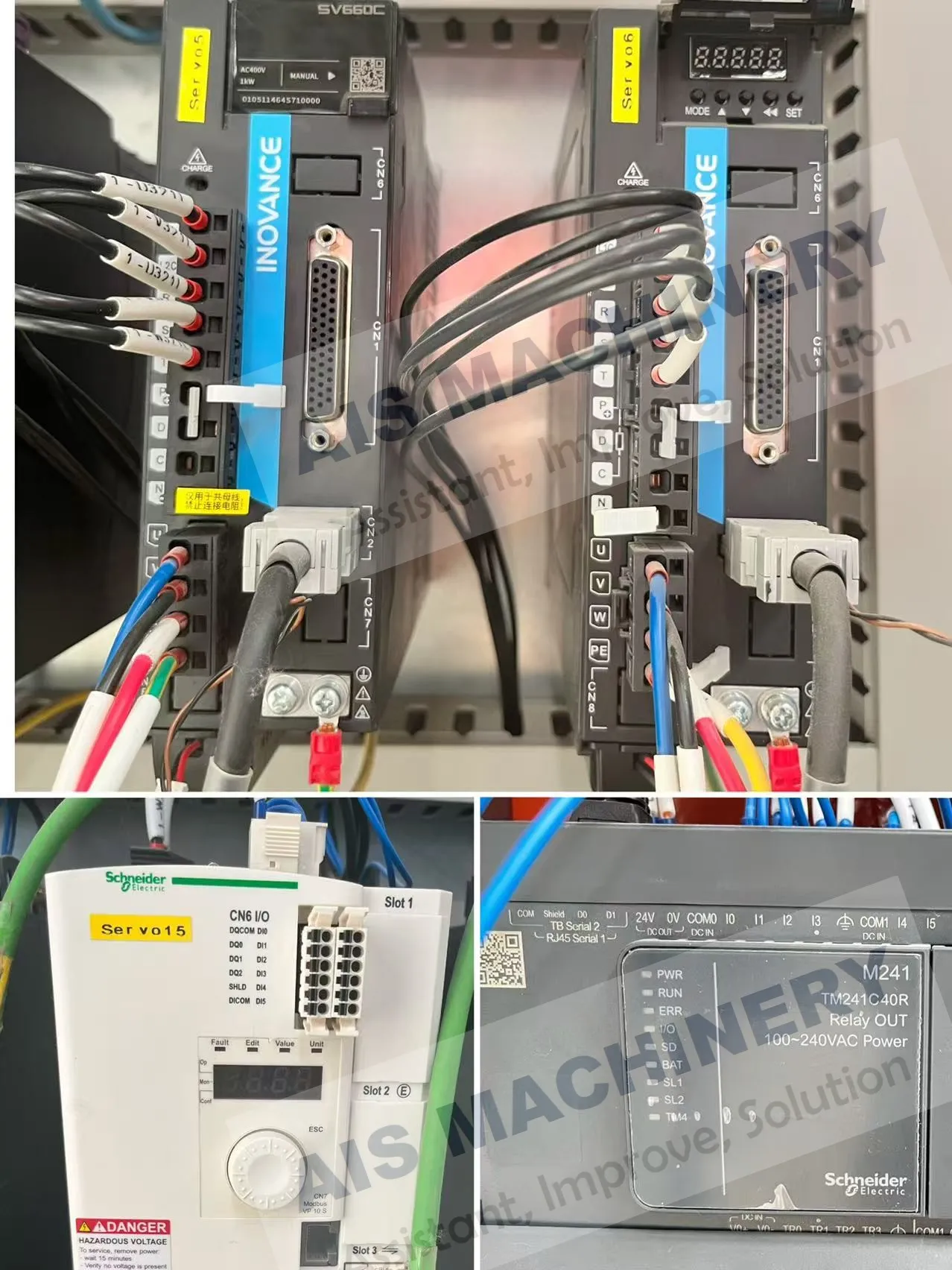

| Control System |

Siemens PLC, touch HMI, encoder feedback |

| Required Power Supply |

380V, 50Hz, 3-phase |

4. Operating Procedure

▶️ Before You Start

-

Check power connection, oil level in hydraulic system, and air pressure.

-

Ensure the punching mold and cutting blade are clean and firmly secured.

-

Load the steel coil on the uncoiler and lock with safety clamps.

▶️ Startup Process

-

System Boot

-

Parameter Input via HMI

-

Input length of frame, punching positions, and number of holes.

-

Set the batch quantity and material thickness.

-

Load or recall saved profile data if applicable.

-

Material Feeding

-

Production Mode

-

Switch to “Auto Run”.

-

Monitor the HMI screen for live speed, punch counts, and cut count.

-

Inspect first 2–3 frames for dimensional accuracy.

▶️ Stopping & Changeover

-

Press “Stop” and wait for the current piece to finish cutting.

-

Change punching dies or adjust rollers if switching frame types.

-

Use jog mode to test feed before resuming auto production.

5. Routine Maintenance

| Task |

Frequency |

Notes |

| Clean roll surfaces |

Daily |

Use anti-rust oil |

| Check punching die wear |

Weekly |

Replace if edge dull |

| Lubricate forming bearings |

Every 2 days |

Use light-grade machine oil |

| Inspect sensors & cables |

Weekly |

Check for wear or disconnection |

| Back up PLC data |

Monthly |

Via USB port on HMI |

6. Troubleshooting Guide

| Symptom |

Possible Cause |

Solution |

| Frame length deviation |

Encoder loose / wrong data |

Recalibrate encoder |

| Punch misalignment |

Servo lag or mold shift |

Reposition mold and reset zero |

| Uneven frame shape |

Roller misadjusted |

Re-level forming station |

| Material jam in cutter |

Blade worn or too slow |

Replace blade, adjust servo timing |

7. Frequently Asked Questions (FAQ)

Q: Is carbon steel strong enough for outdoor frames?

A: Yes. With proper galvanization or powder coating, carbon steel frames offer excellent strength and corrosion resistance at a much lower cost than aluminum.

Q: Can one machine make different sizes?

A: Absolutely. Frame length, hole positions, and even roll gaps can be adjusted via PLC. Some wider profiles may need partial tool change.

Q: What is the estimated tool life?

A: Punching dies typically last 80,000–120,000 cycles depending on material. Cutting blades may last 30,000–50,000 cuts with proper lubrication.

Q: Can I integrate a stacker later?

A: Yes. The output section includes optional ports and logic for integration with auto stackers or robotic arms.

8. Safety Instructions

-

Never place hands near the roll station during operation.

-

Always disconnect power before adjusting tooling.

-

Emergency stops are located at the entry and exit ends.

-

Wear gloves and safety glasses when changing dies.

Cette bande dans les stands de profilage se transforme progressivement vers sa forme finale. Ce procédé respecte les contraintes mécaniques et caractéristiques du métal et permet l'utilisation de multiples nuances d'aciers. Deux arbres horizontaux de chaque tête sont commandés par le moteur de la machine, ce qui assure un entraînement régulier de la bande. Lors du profilage à froid, des opérations telles que le poinçonnage de trous, l'emboutissage de logo, peuvent être réalisées en ligne.

Ensuite, la section métallique finale est coupée par une machine de coupe servo hydraulique à la longueur souhaitée.

1. À quoi sert une profileuse ?

Les machines de formage à froid sont utilisées dans de nombreux secteurs, notamment la construction, l'automobile, l'aérospatiale et la fabrication. Elles sont hautement automatisées et peuvent produire des produits de haute qualité à grande vitesse, ce qui en fait un choix populaire pour la production de masse.

4. Le flux technique de la ligne de production

{Steel Tape}→ Uncoiler →Strip-head Cutter and welder→Spiral accumulator→Forming section →Hole punching device→Hydraulic servo driven cutoff→→ Run-out table

EQUIPEMENT DE RELATION

Nous fournissons tout l'équipement pour la section d'entrée du laminoir à tubes :

Voiture à bobine

Dérouleur à tête simple et double et dérouleur hydraulique et pneumatique

Bras d'éplucheur et de maintien du rouleau

Machine à aplatir

Cisailleuse et soudeuse bout à bout automatique et semi-automatique

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

SECTION DE FINITION DU LAMINEUR À TUBES

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

9. Drilling machine

PIÈCES DE RECHANGE AU CHOIX

Nos pièces de rechange s'appliquent :

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

NOTRE CERTIFICAT

NOTRE SERVICE

Pourquoi nous choisir?

Technologie de pointe, qualité fiable, excellent service !

Conception optimisée, sélection de matériaux de haute qualité !

Garantie du processus de traitement thermique !

Engrenage conique hélicoïdal, accouplement à tambour et cémentation.

Trempe des dents d'engrenages.

Système d'entraînement stable, efficace et portable avec moins de bruit.

Haute précision, résistance à l'usure et longue durée de vie des rouleaux.

Tous les tours mécaniques, les rainures de clavette sont positionnés et fraisés par CNC.

Notre service

Service avant-vente

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

Service après-vente

1. Nous livrerons la machine et fournirons les documents à temps pour nous assurer que vous pouvez obtenir la machine rapidement

2. Lorsque vous avez terminé les conditions de préparation, notre équipe d'ingénieurs du service après-vente rapide et professionnel se rendra dans votre usine pour installer la machine, vous remettre le manuel d'utilisation et former votre employé jusqu'à ce qu'il puisse bien utiliser la machine.

3. Nous offrons une garantie d'un an et un support technique à vie.

4. Un personnel bien formé et expérimenté répondra à toutes vos demandes en anglais et en chinois

5,24 heures pour l'intervention de l'ingénieur.

6. Votre relation commerciale avec nous sera confidentielle envers tout tiers.

Contrôle de qualité

Nous disposons d'un département de qualité unique, qui garantit que le matériau des matières premières est bon et garantit le bon fonctionnement de la machine.

Tél. : 86-15176910262

Tél. : 86-15176910262