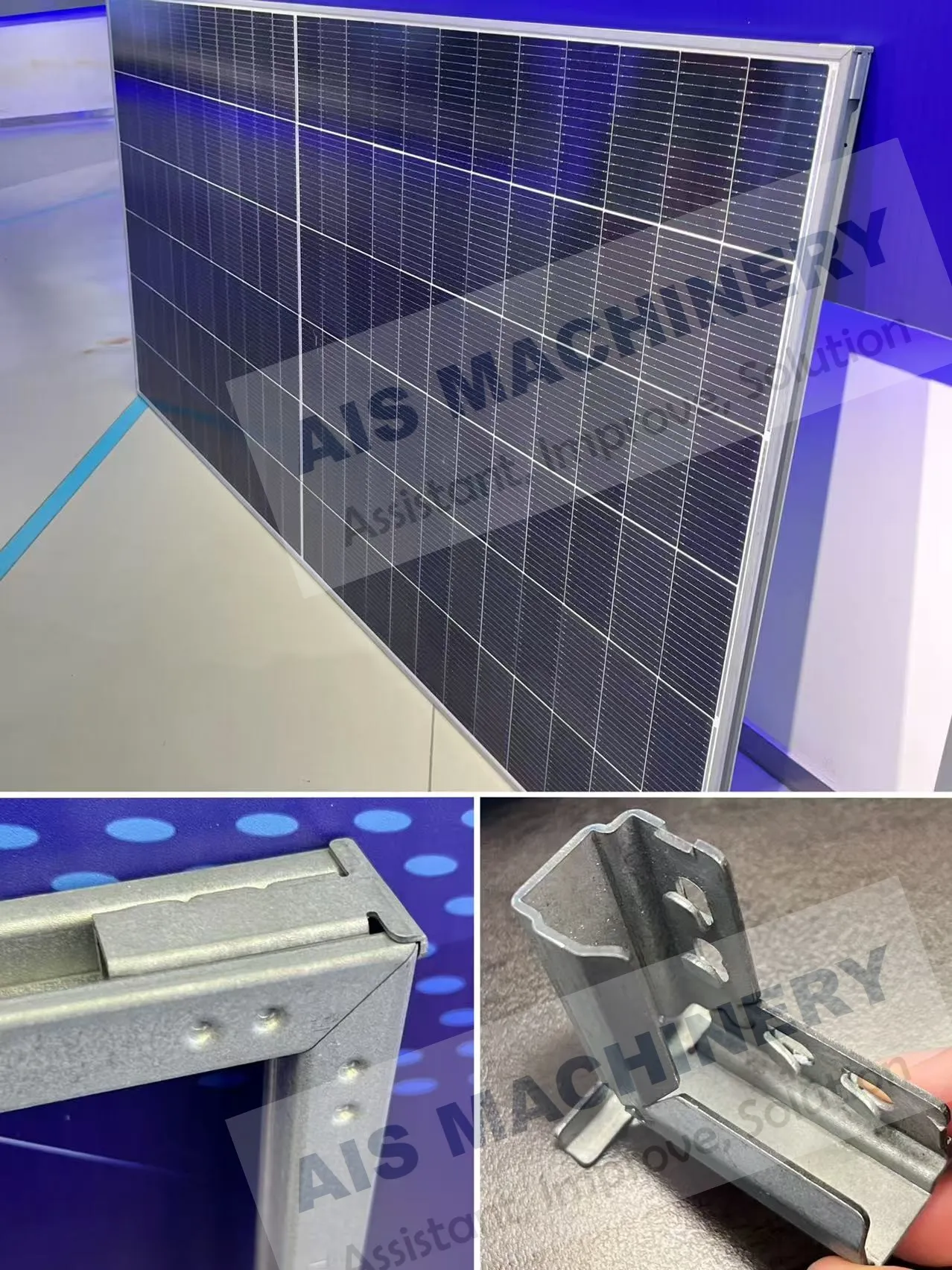

Solar Panel Frame Roll Forming Machine (Carbon Steel Type)

1. Introduction

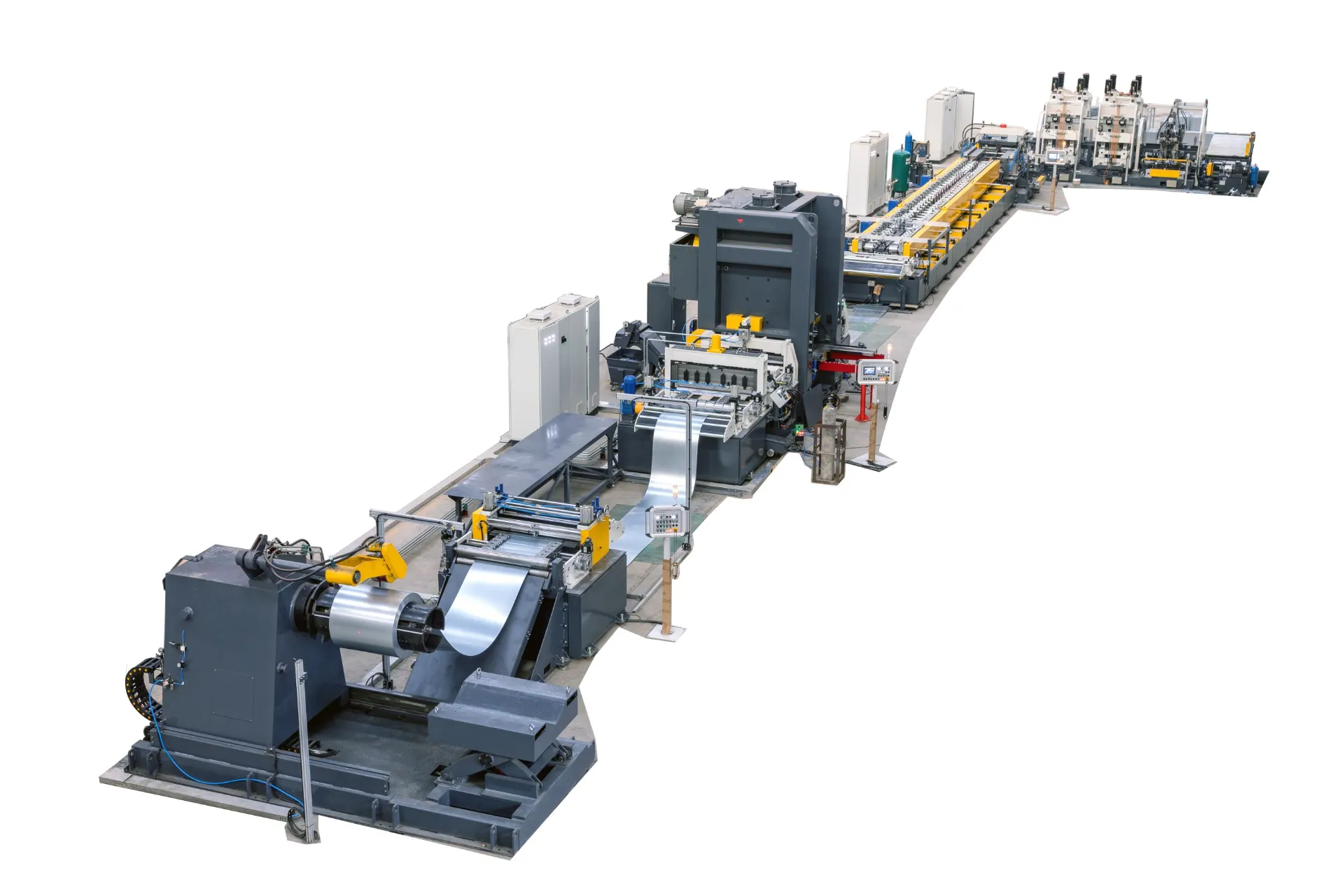

This roll forming line is engineered for manufacturing carbon steel frames used in photovoltaic (PV) solar panels. Designed for stability and efficiency, the machine automates punching, forming, and cutting in a continuous process, allowing for high-precision frame production with minimal material waste.

This model is optimized for long-run production with programmable control and real-time diagnostics.

2. Machine Composition

The system is composed of the following modules:

-

Manual Decoiler or Hydraulic Uncoiler

-

Feeding and Leveling System

-

Precision Servo Punching Station

-

Main Roll Forming Section

-

Servo Flying Shear Cut-Off Unit

-

Runout Table and Optional Auto Stacker

-

Centralized Electrical Control System (PLC + HMI)

3. Technical Data

| Parameter |

Specification |

| Frame Material |

Cold rolled carbon steel, galvanized steel |

| Material Width |

45 – 100 mm |

| Material Thickness |

0.8 – 2.0 mm |

| Production Speed |

Up to 15 meters per minute |

| Forming Stations |

14 – 20 steps (customizable) |

| Cutting Tolerance |

±0.3 mm |

| Punching Accuracy |

±0.5 mm |

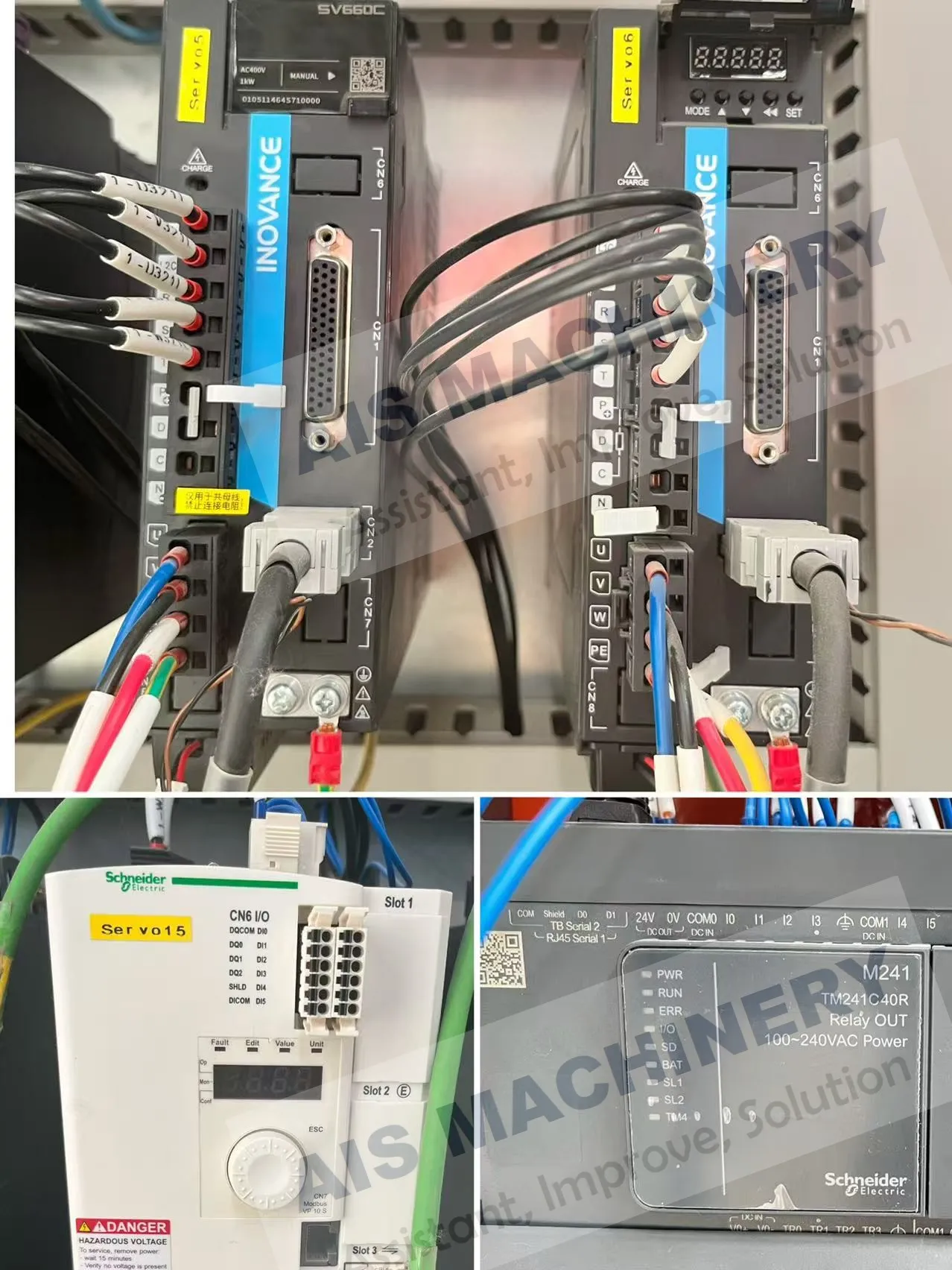

| Control System |

Siemens PLC, touch HMI, encoder feedback |

| Required Power Supply |

380V, 50Hz, 3-phase |

4. Operating Procedure

▶️ Before You Start

-

Check power connection, oil level in hydraulic system, and air pressure.

-

Ensure the punching mold and cutting blade are clean and firmly secured.

-

Load the steel coil on the uncoiler and lock with safety clamps.

▶️ Startup Process

-

System Boot

-

Parameter Input via HMI

-

Input length of frame, punching positions, and number of holes.

-

Set the batch quantity and material thickness.

-

Load or recall saved profile data if applicable.

-

Material Feeding

-

Production Mode

-

Switch to “Auto Run”.

-

Monitor the HMI screen for live speed, punch counts, and cut count.

-

Inspect first 2–3 frames for dimensional accuracy.

▶️ Stopping & Changeover

-

Press “Stop” and wait for the current piece to finish cutting.

-

Change punching dies or adjust rollers if switching frame types.

-

Use jog mode to test feed before resuming auto production.

5. Routine Maintenance

| Task |

Frequency |

Notes |

| Clean roll surfaces |

Daily |

Use anti-rust oil |

| Check punching die wear |

Weekly |

Replace if edge dull |

| Lubricate forming bearings |

Every 2 days |

Use light-grade machine oil |

| Inspect sensors & cables |

Weekly |

Check for wear or disconnection |

| Back up PLC data |

Monthly |

Via USB port on HMI |

6. Troubleshooting Guide

| Symptom |

Possible Cause |

Solution |

| Frame length deviation |

Encoder loose / wrong data |

Recalibrate encoder |

| Punch misalignment |

Servo lag or mold shift |

Reposition mold and reset zero |

| Uneven frame shape |

Roller misadjusted |

Re-level forming station |

| Material jam in cutter |

Blade worn or too slow |

Replace blade, adjust servo timing |

7. Frequently Asked Questions (FAQ)

Q: Is carbon steel strong enough for outdoor frames?

A: Yes. With proper galvanization or powder coating, carbon steel frames offer excellent strength and corrosion resistance at a much lower cost than aluminum.

Q: Can one machine make different sizes?

A: Absolutely. Frame length, hole positions, and even roll gaps can be adjusted via PLC. Some wider profiles may need partial tool change.

Q: What is the estimated tool life?

A: Punching dies typically last 80,000–120,000 cycles depending on material. Cutting blades may last 30,000–50,000 cuts with proper lubrication.

Q: Can I integrate a stacker later?

A: Yes. The output section includes optional ports and logic for integration with auto stackers or robotic arms.

8. Safety Instructions

-

Never place hands near the roll station during operation.

-

Always disconnect power before adjusting tooling.

-

Emergency stops are located at the entry and exit ends.

-

Wear gloves and safety glasses when changing dies.

Profilli stendlardagi bu chiziq asta-sekin yakuniy shakliga o'zgaradi. Bu jarayon metallning mexanik va xarakterli kuchlanishlarini hurmat qiladi va bir nechta po'latdan foydalanish imkonini beradi. Har bir boshning ikkita gorizontal vali mashinaning motori tomonidan boshqariladi, bu chiziqning muntazam harakatlanishini ta'minlaydi. Sovuq rulonni shakllantirish jarayonida logotiplarni teshish, teshiklarni teshish kabi operatsiyalarni onlayn bajarish mumkin.

Keyinchalik, oxirgi metall qism gidravlik servo kesish mashinasi tomonidan kerakli uzunlikka kesiladi.

1.Rumni shakllantirish mashinasi nima uchun ishlatiladi?

Sovuq rulonni shakllantirish mashinalari qurilish, avtomobilsozlik, aerokosmik va ishlab chiqarishni o'z ichiga olgan turli sohalarda qo'llaniladi. Ular yuqori darajada avtomatlashtirilgan va yuqori tezlikda yuqori sifatli mahsulotlarni ishlab chiqarishi mumkin, bu ularni ommaviy ishlab chiqarish uchun mashhur tanlovga aylantiradi.

4. Ishlab chiqarish liniyasining texnik oqimi

{Steel Tape}→ Uncoiler →Strip-head Cutter and welder→Spiral accumulator→Forming section →Hole punching device→Hydraulic servo driven cutoff→→ Run-out table

ALOQA QUVVATLARI

Biz quvur tegirmonining kirish qismiga barcha jihozlarni taqdim etamiz:

Bobinli avtomobil

Yagona va ikki boshli sarg'ish va gidravlik va pnevmatik sarg'ish

Peel va rulonli qo'lni ushlab turing

Yassilash mashinasi

Avtomatik va yarim avtomatik qirqimchi va payvandchi

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

QUVUR TEGIRMASINI TUGLASH BO'limi

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

9. Drilling machine

TANLASH UCHUN EHTIYOT QISMLAR

Bizning ehtiyot qismlarimiz qo'llaniladi:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

BIZNING SERTIFIKAT

BIZNING XIZMAT

Nima uchun bizni tanlaysiz?

Etakchi texnologiya, ishonchli sifat, zo'r xizmat!

Optimallashtirilgan dizayn, yuqori sifatli materialni tanlang!

Issiqlik bilan ishlov berish jarayoni kafolati!

Spiral konusli tishli, barabanli tishli ulanish va karbürizatsiya.

Tishli tishlarni o'chirish.

Boshqariladigan tizim barqaror, samarali va past shovqin bilan taqiladigan.

Yuqori aniqlikdagi aşınmaya bardoshli va rulonlarning uzoq umri.

Barcha dastgoh stanoklari, kalit yivlari CNC tomonidan joylashtirilgan va frezalangan.

Bizning xizmatimiz

Sotishdan oldingi xizmat

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

Sotishdan keyingi xizmat

1.Mashinani tezda olishingizga ishonch hosil qilish uchun biz mashinani yetkazib beramiz va hujjatlarni o'z vaqtida taqdim etamiz

2. Tayyorgarlik shartlarini tugatgandan so'ng, bizning tez va professional sotuvdan keyingi xizmat ko'rsatish bo'yicha muhandis jamoamiz mashinani o'rnatish uchun zavodingizga boradi, sizga foydalanish qo'llanmasini beradi va ishchingizni mashinani yaxshi boshqara olmaguncha o'rgatadi.

3.Biz bir yillik kafolat va umrbod texnik yordamni taqdim etamiz.

4. Yaxshi o'qitilgan va tajribali xodimlar sizning barcha so'rovlaringizga ingliz va xitoy tillarida javob berishlari kerak

Muhandis javobi uchun 5 .24 soat.

6.Biz bilan bo'lgan biznes munosabatlaringiz har qanday uchinchi tomon uchun maxfiy bo'ladi.

Sifat nazorati

Bizda yagona sifat bo'limi mavjud bo'lib, u xomashyo materialining yaxshi ekanligiga ishonch hosil qiladi va mashinaning muammosiz ishlashini ta'minlaydi.

Tel: 86-15176910262

Tel: 86-15176910262