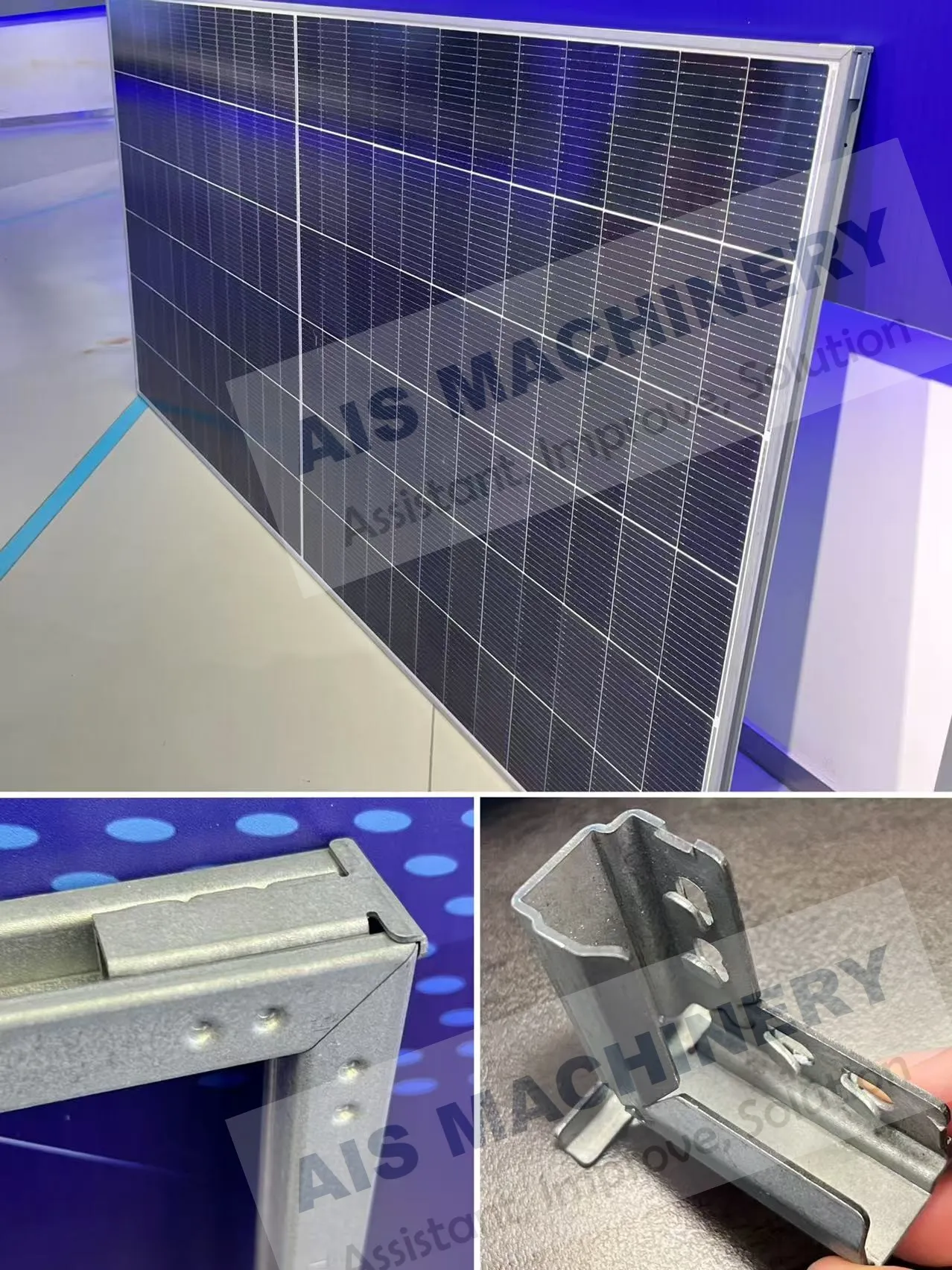

Solar Panel Frame Roll Forming Machine (Carbon Steel Type)

1. Introduction

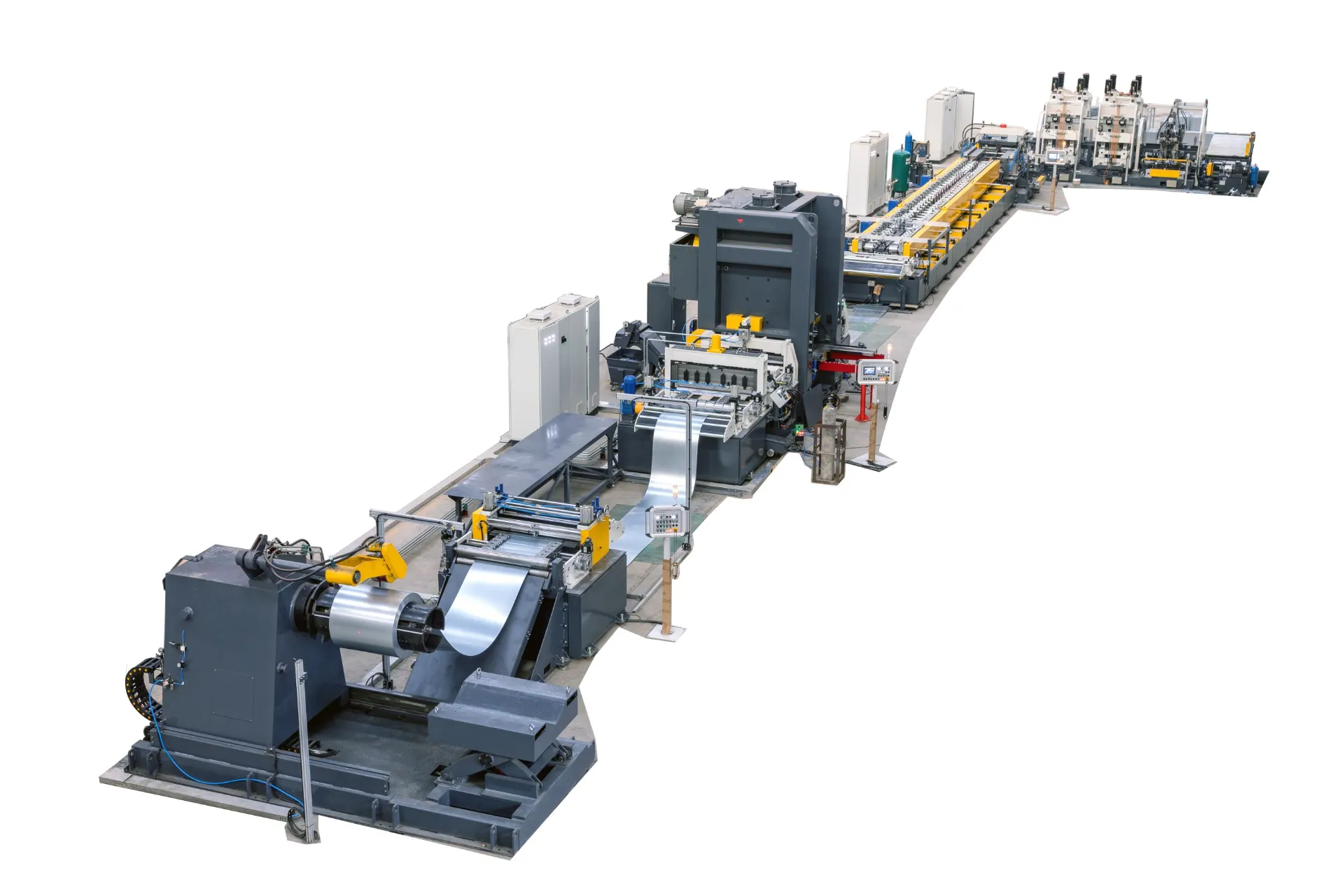

This roll forming line is engineered for manufacturing carbon steel frames used in photovoltaic (PV) solar panels. Designed for stability and efficiency, the machine automates punching, forming, and cutting in a continuous process, allowing for high-precision frame production with minimal material waste.

This model is optimized for long-run production with programmable control and real-time diagnostics.

2. Machine Composition

The system is composed of the following modules:

-

Manual Decoiler or Hydraulic Uncoiler

-

Feeding and Leveling System

-

Precision Servo Punching Station

-

Main Roll Forming Section

-

Servo Flying Shear Cut-Off Unit

-

Runout Table and Optional Auto Stacker

-

Centralized Electrical Control System (PLC + HMI)

3. Technical Data

| Parameter |

Specification |

| Frame Material |

Cold rolled carbon steel, galvanized steel |

| Material Width |

45 – 100 mm |

| Material Thickness |

0.8 – 2.0 mm |

| Production Speed |

Up to 15 meters per minute |

| Forming Stations |

14 – 20 steps (customizable) |

| Cutting Tolerance |

±0.3 mm |

| Punching Accuracy |

±0.5 mm |

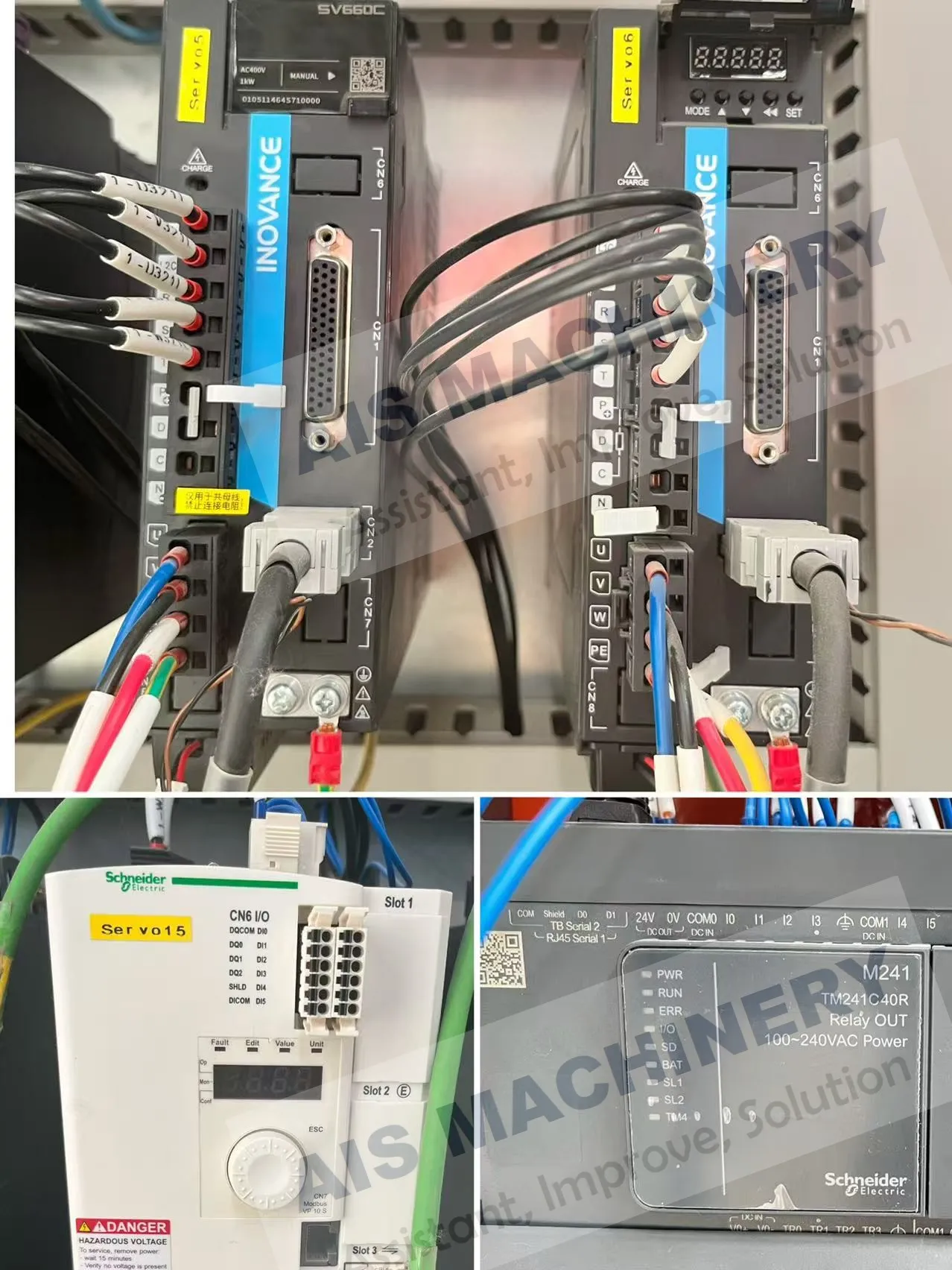

| Control System |

Siemens PLC, touch HMI, encoder feedback |

| Required Power Supply |

380V, 50Hz, 3-phase |

4. Operating Procedure

▶️ Before You Start

-

Check power connection, oil level in hydraulic system, and air pressure.

-

Ensure the punching mold and cutting blade are clean and firmly secured.

-

Load the steel coil on the uncoiler and lock with safety clamps.

▶️ Startup Process

-

System Boot

-

Parameter Input via HMI

-

Input length of frame, punching positions, and number of holes.

-

Set the batch quantity and material thickness.

-

Load or recall saved profile data if applicable.

-

Material Feeding

-

Production Mode

-

Switch to “Auto Run”.

-

Monitor the HMI screen for live speed, punch counts, and cut count.

-

Inspect first 2–3 frames for dimensional accuracy.

▶️ Stopping & Changeover

-

Press “Stop” and wait for the current piece to finish cutting.

-

Change punching dies or adjust rollers if switching frame types.

-

Use jog mode to test feed before resuming auto production.

5. Routine Maintenance

| Task |

Frequency |

Notes |

| Clean roll surfaces |

Daily |

Use anti-rust oil |

| Check punching die wear |

Weekly |

Replace if edge dull |

| Lubricate forming bearings |

Every 2 days |

Use light-grade machine oil |

| Inspect sensors & cables |

Weekly |

Check for wear or disconnection |

| Back up PLC data |

Monthly |

Via USB port on HMI |

6. Troubleshooting Guide

| Symptom |

Possible Cause |

Solution |

| Frame length deviation |

Encoder loose / wrong data |

Recalibrate encoder |

| Punch misalignment |

Servo lag or mold shift |

Reposition mold and reset zero |

| Uneven frame shape |

Roller misadjusted |

Re-level forming station |

| Material jam in cutter |

Blade worn or too slow |

Replace blade, adjust servo timing |

7. Frequently Asked Questions (FAQ)

Q: Is carbon steel strong enough for outdoor frames?

A: Yes. With proper galvanization or powder coating, carbon steel frames offer excellent strength and corrosion resistance at a much lower cost than aluminum.

Q: Can one machine make different sizes?

A: Absolutely. Frame length, hole positions, and even roll gaps can be adjusted via PLC. Some wider profiles may need partial tool change.

Q: What is the estimated tool life?

A: Punching dies typically last 80,000–120,000 cycles depending on material. Cutting blades may last 30,000–50,000 cuts with proper lubrication.

Q: Can I integrate a stacker later?

A: Yes. The output section includes optional ports and logic for integration with auto stackers or robotic arms.

8. Safety Instructions

-

Never place hands near the roll station during operation.

-

Always disconnect power before adjusting tooling.

-

Emergency stops are located at the entry and exit ends.

-

Wear gloves and safety glasses when changing dies.

Esta tira nos suportes de perfilagem transforma-se progressivamente em direção à sua forma final. Este processo respeita as tensões mecânicas e características do metal e permite o uso de vários tipos de aços. Dois eixos horizontais de cada cabeça são controlados pelo motor da máquina, o que garante um acionamento regular da tira. Durante a conformação a frio, operações como perfuração de furos e estampagem de logotipo podem ser feitas on-line.

Em seguida, a seção final de metal é cortada pela máquina de corte servo hidráulica no comprimento desejado.

1. Para que é usada uma máquina de conformação de rolos?

As máquinas de conformação a frio são usadas em uma variedade de indústrias, incluindo construção, automotiva, aeroespacial e manufatura. Elas são altamente automatizadas e podem produzir produtos de alta qualidade em alta velocidade, tornando-as uma escolha popular para produção em massa.

4. O fluxo técnico da linha de produção

{Steel Tape}→ Uncoiler →Strip-head Cutter and welder→Spiral accumulator→Forming section →Hole punching device→Hydraulic servo driven cutoff→→ Run-out table

EQUIPAMENTO DE RELACIONAMENTO

Nós fornecemos todos os equipamentos para a seção de entrada do moinho de tubos:

Carro de bobina

Desbobinador de cabeça simples e dupla e desbobinador hidráulico e pneumático

Descascador e braço de rolo de retenção

Máquina de achatamento

Cortador automático e semiautomático e soldador de topo

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

SEÇÃO DE ACABAMENTO DE MOINHO DE TUBOS

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

9. Drilling machine

PEÇAS DE REPOSIÇÃO PARA ESCOLHER

Nossas peças de reposição se aplicam:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

NOSSO CERTIFICADO

NOSSO SERVIÇO

Por que nos escolher?

Tecnologia de ponta, qualidade confiável, serviço excelente!

Design otimizado, seleção de materiais de alta qualidade!

Garantia do processo de tratamento térmico!

Engrenagem cônica espiral, acoplamento de engrenagem de tambor e cementação.

Têmpera dos dentes da engrenagem.

Sistema acionado estável, eficiente e usável com menor ruído.

Alta precisão, resistência ao desgaste e longa vida útil dos rolos.

Todos os tornos e ranhuras de máquinas são posicionados e fresados por CNC.

Nosso serviço

Serviço de pré-venda

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

Serviço pós-venda

1. Nós entregaremos a máquina e forneceremos os documentos a tempo para garantir que você possa obtê-la rapidamente

2. Quando você terminar as condições de preparação, nossa equipe de engenheiros de serviço pós-venda rápida e profissional irá até sua fábrica para instalar a máquina, fornecer o manual de operação e treinar seus funcionários até que eles possam operar bem a máquina.

3. Oferecemos garantia de um ano e suporte técnico vitalício.

4. Uma equipe bem treinada e experiente responderá a todas as suas perguntas em inglês e chinês

5,24 horas para resposta do engenheiro.

6. Seu relacionamento comercial conosco será confidencial para terceiros.

Controle de qualidade

Temos um único departamento de qualidade que garante que a matéria-prima seja boa e que a máquina funcione sem problemas.

Telefone:86-15176910262

Telefone:86-15176910262