The cage accumulator is a commonly used material storage device in ERW tube mill production lines. It serves as a buffer between the uncoiler, shear and butt welder, and the forming mill, ensuring continuous production without interruption and improving the overall line efficiency.

The steel strip is stored helically around a vertical cage frame, maintaining stable strip tension and allowing quick feeding.

It is suitable for the production of carbon steel, stainless steel, and alloy steel pipes, especially for medium to high-capacity requirements.

1. Application Solutions

-

Standard Solution:

Uncoiler → Shear & Butt Welder → Cage Accumulator → Forming Mill → Welding/Sizing → Flying Saw → Stacking.

-

High-Speed Upgrade:

Integrates with automatic uncoiler, double-head shear and butt welder, and PLC-based speed control for fully automated production lines.

-

Heavy-Duty Solution:

Reinforced cage frame with servo-controlled tension system, suitable for producing high-strength steel strips of thickness 3.0–4.5mm and above.

2. Technical Requirements

-

The cage frame must adopt high-strength welded structure, with shot blasting and anti-corrosion treatment.

-

Key rotating parts shall be equipped with imported bearings to ensure stable and vibration-free operation.

-

Tension control system must respond quickly to avoid strip slack or breakage.

-

Anti-strip-jumping devices must be installed for high-speed running safety.

-

Emergency stop system and protective fencing must meet CE or local safety standards.

-

Maintenance access doors must be provided for easy servicing.

3. Technical Specifications (Customizable)

| Item |

Parameter |

| Applicable Strip Width |

60mm–600mm (customizable) |

| Applicable Strip Thickness |

0.5mm–4.5mm |

| Storage Capacity |

100m–250m (customizable) |

| Floor Space Required |

Approx. L5m × W1m × H4m |

| Max. Strip Speed |

80–120m/min (depends on line design) |

| Cage Frame Material |

High-strength alloy steel |

| Tension Adjustment |

Electric/Pneumatic control |

| Safety Features |

Limit switches, anti-strip-jumping fence, emergency braking |

4. Key Advantages of Cage Accumulator

-

Simple structure, cost-effective: About 20% lower cost compared to disk accumulators.

-

Easy maintenance: Mostly mechanical parts, simple and low-cost servicing.

-

Stable operation: Natural helical storage ensures uniform strip tension, reducing forming defects.

-

Strong adaptability: Suitable for various materials and strip thicknesses.

-

Moderate footprint: Saves about 30% of space compared to traditional horizontal accumulators.

5. Comparison Between Cage Accumulator and Disk Accumulator

Summary:

If ultra-high speed (150m/min and above) is required, a disk accumulator is preferred.

For standard medium-high speed tube mills, a cage accumulator is the optimal choice considering cost and reliability.

6. Cage Accumulator Selection Guide

【Notes on Selection】

-

Strip width and thickness are the basic criteria for selecting the cage accumulator model.

-

Line speed determines whether enhanced tension control and safety features are needed.

-

Factory layout restrictions and surface protection needs should be communicated early for tailored designs.

-

For cost-performance balance, the standard medium-duty cage accumulator is recommended for most ERW production lines.

ALOQA QUVVATLARI

Biz quvur tegirmonining kirish qismiga barcha jihozlarni taqdim etamiz:

Bobinli avtomobil

Yagona va ikki boshli sarg'ish va gidravlik va pnevmatik sarg'ish

Peel va rulonli qo'lni ushlab turing

Yassilash mashinasi

Avtomatik va yarim avtomatik qirqimchi va payvandchi

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

BIZNING XIZMAT

Nima uchun bizni tanlaysiz?

Etakchi texnologiya, ishonchli sifat, zo'r xizmat!

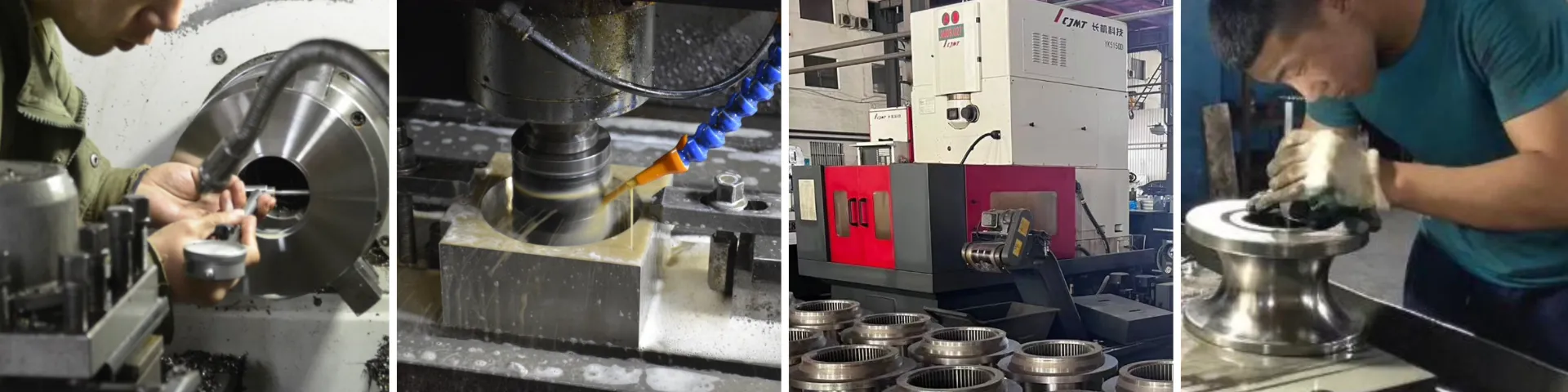

Optimallashtirilgan dizayn, yuqori sifatli materialni tanlang!

Issiqlik bilan ishlov berish jarayoni kafolati!

Spiral konusli tishli, barabanli tishli ulanish va karbürizatsiya.

Tishli tishlarni o'chirish.

Boshqariladigan tizim barqaror, samarali va past shovqin bilan taqiladigan.

Yuqori aniqlikdagi aşınmaya bardoshli va rulonlarning uzoq umri.

Barcha dastgoh stanoklari, kalit yivlari CNC tomonidan joylashtirilgan va frezalangan.

Sotishdan keyingi xizmat

1.Mashinani tezda olishingizga ishonch hosil qilish uchun biz mashinani yetkazib beramiz va hujjatlarni o'z vaqtida taqdim etamiz

2. Tayyorgarlik shartlarini tugatgandan so'ng, bizning tez va professional sotuvdan keyingi xizmat ko'rsatish bo'yicha muhandis jamoamiz mashinani o'rnatish uchun zavodingizga boradi, sizga foydalanish qo'llanmasini beradi va ishchingizni mashinani yaxshi boshqara olmaguncha o'rgatadi.

3.Biz bir yillik kafolat va umrbod texnik yordamni taqdim etamiz.

4. Yaxshi o'qitilgan va tajribali xodimlar sizning barcha so'rovlaringizga ingliz va xitoy tillarida javob berishlari kerak

Muhandis javobi uchun 5 .24 soat.

6.Biz bilan bo'lgan biznes munosabatlaringiz har qanday uchinchi tomon uchun maxfiy bo'ladi.

Sifat nazorati

Bizda yagona sifat bo'limi mavjud bo'lib, u xomashyo materialining yaxshi ekanligiga ishonch hosil qiladi va mashinaning muammosiz ishlashini ta'minlaydi.

Tel: 86-15176910262

Tel: 86-15176910262