The cage accumulator is a commonly used material storage device in ERW tube mill production lines. It serves as a buffer between the uncoiler, shear and butt welder, and the forming mill, ensuring continuous production without interruption and improving the overall line efficiency.

The steel strip is stored helically around a vertical cage frame, maintaining stable strip tension and allowing quick feeding.

It is suitable for the production of carbon steel, stainless steel, and alloy steel pipes, especially for medium to high-capacity requirements.

1. Application Solutions

-

Standard Solution:

Uncoiler → Shear & Butt Welder → Cage Accumulator → Forming Mill → Welding/Sizing → Flying Saw → Stacking.

-

High-Speed Upgrade:

Integrates with automatic uncoiler, double-head shear and butt welder, and PLC-based speed control for fully automated production lines.

-

Heavy-Duty Solution:

Reinforced cage frame with servo-controlled tension system, suitable for producing high-strength steel strips of thickness 3.0–4.5mm and above.

2. Technical Requirements

-

The cage frame must adopt high-strength welded structure, with shot blasting and anti-corrosion treatment.

-

Key rotating parts shall be equipped with imported bearings to ensure stable and vibration-free operation.

-

Tension control system must respond quickly to avoid strip slack or breakage.

-

Anti-strip-jumping devices must be installed for high-speed running safety.

-

Emergency stop system and protective fencing must meet CE or local safety standards.

-

Maintenance access doors must be provided for easy servicing.

3. Technical Specifications (Customizable)

| Item |

Parameter |

| Applicable Strip Width |

60mm–600mm (customizable) |

| Applicable Strip Thickness |

0.5mm–4.5mm |

| Storage Capacity |

100m–250m (customizable) |

| Floor Space Required |

Approx. L5m × W1m × H4m |

| Max. Strip Speed |

80–120m/min (depends on line design) |

| Cage Frame Material |

High-strength alloy steel |

| Tension Adjustment |

Electric/Pneumatic control |

| Safety Features |

Limit switches, anti-strip-jumping fence, emergency braking |

4. Key Advantages of Cage Accumulator

-

Simple structure, cost-effective: About 20% lower cost compared to disk accumulators.

-

Easy maintenance: Mostly mechanical parts, simple and low-cost servicing.

-

Stable operation: Natural helical storage ensures uniform strip tension, reducing forming defects.

-

Strong adaptability: Suitable for various materials and strip thicknesses.

-

Moderate footprint: Saves about 30% of space compared to traditional horizontal accumulators.

5. Comparison Between Cage Accumulator and Disk Accumulator

Summary:

If ultra-high speed (150m/min and above) is required, a disk accumulator is preferred.

For standard medium-high speed tube mills, a cage accumulator is the optimal choice considering cost and reliability.

6. Cage Accumulator Selection Guide

【Notes on Selection】

-

Strip width and thickness are the basic criteria for selecting the cage accumulator model.

-

Line speed determines whether enhanced tension control and safety features are needed.

-

Factory layout restrictions and surface protection needs should be communicated early for tailored designs.

-

For cost-performance balance, the standard medium-duty cage accumulator is recommended for most ERW production lines.

関係機器

当社はチューブミル入口セクションに必要なすべての機器を提供します:

コイルカー

シングルヘッドおよびダブルヘッドアンコイラーと油圧式および空気圧式アンコイラー

ピーラーとロールアームの押さえ

平坦化機

自動および半自動せん断機と突合せ溶接機

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

当社のサービス

当社を選ぶ理由

最先端の技術、信頼できる品質、優れたサービス!

最適化されたデザイン、高品質の素材を選択!

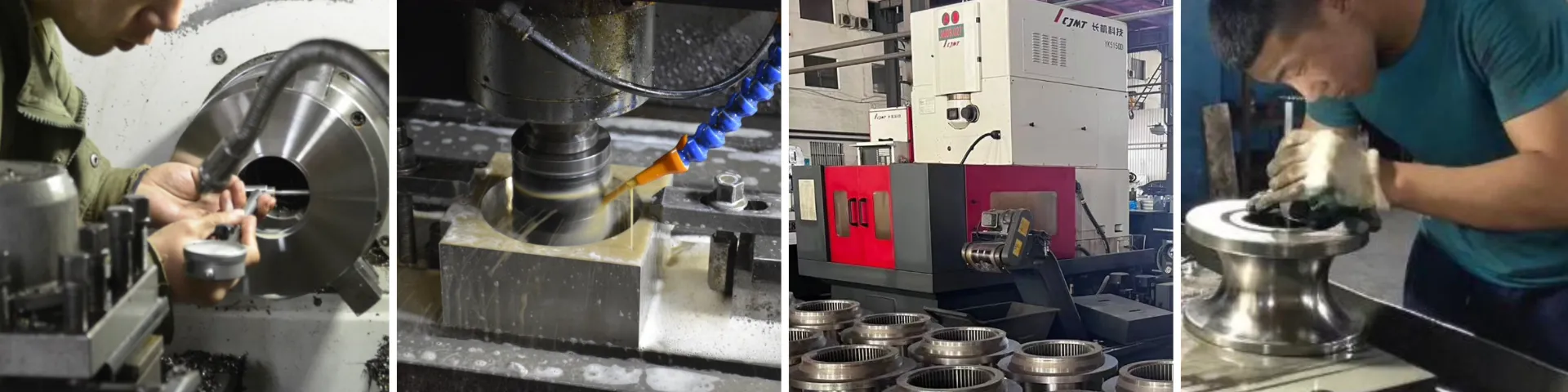

熱処理工程保証!

スパイラルベベルギア、ドラムギアカップリング、浸炭処理。

ギア歯の焼入れ。

駆動システムは安定性、効率性、装着性、低ノイズを実現。

高精度の耐摩耗性とローラーの長寿命。

すべての機械旋盤、キー溝は CNC によって位置決めおよびフライス加工されます。

アフターサービス

1.機械を迅速にお届けできるよう、機械を納品し、書類を時間通りにご提供します。

2. 準備条件が完了すると、当社の迅速かつ専門的なアフターサービスエンジニアチームがお客様の工場に出向き、機械を設置し、操作マニュアルをお渡しし、従業員が機械をうまく操作できるようになるまでトレーニングを行います。

3. 1 年間の保証と生涯にわたる技術サポートを提供します。

4. 十分な訓練を受けた経験豊富なスタッフが英語と中国語ですべてのお問い合わせにお答えします。

エンジニアの対応には5~24時間かかります。

6. お客様と当社とのビジネス関係はいかなる第三者に対しても秘密にされます。

品質管理

当社には、原材料の品質を保証し、機械がスムーズに稼働することを保証する単一の品質管理部門があります。