The cage accumulator is a commonly used material storage device in ERW tube mill production lines. It serves as a buffer between the uncoiler, shear and butt welder, and the forming mill, ensuring continuous production without interruption and improving the overall line efficiency.

The steel strip is stored helically around a vertical cage frame, maintaining stable strip tension and allowing quick feeding.

It is suitable for the production of carbon steel, stainless steel, and alloy steel pipes, especially for medium to high-capacity requirements.

1. Application Solutions

-

Standard Solution:

Uncoiler → Shear & Butt Welder → Cage Accumulator → Forming Mill → Welding/Sizing → Flying Saw → Stacking.

-

High-Speed Upgrade:

Integrates with automatic uncoiler, double-head shear and butt welder, and PLC-based speed control for fully automated production lines.

-

Heavy-Duty Solution:

Reinforced cage frame with servo-controlled tension system, suitable for producing high-strength steel strips of thickness 3.0–4.5mm and above.

2. Technical Requirements

-

The cage frame must adopt high-strength welded structure, with shot blasting and anti-corrosion treatment.

-

Key rotating parts shall be equipped with imported bearings to ensure stable and vibration-free operation.

-

Tension control system must respond quickly to avoid strip slack or breakage.

-

Anti-strip-jumping devices must be installed for high-speed running safety.

-

Emergency stop system and protective fencing must meet CE or local safety standards.

-

Maintenance access doors must be provided for easy servicing.

3. Technical Specifications (Customizable)

| Item |

Parameter |

| Applicable Strip Width |

60mm–600mm (customizable) |

| Applicable Strip Thickness |

0.5mm–4.5mm |

| Storage Capacity |

100m–250m (customizable) |

| Floor Space Required |

Approx. L5m × W1m × H4m |

| Max. Strip Speed |

80–120m/min (depends on line design) |

| Cage Frame Material |

High-strength alloy steel |

| Tension Adjustment |

Electric/Pneumatic control |

| Safety Features |

Limit switches, anti-strip-jumping fence, emergency braking |

4. Key Advantages of Cage Accumulator

-

Simple structure, cost-effective: About 20% lower cost compared to disk accumulators.

-

Easy maintenance: Mostly mechanical parts, simple and low-cost servicing.

-

Stable operation: Natural helical storage ensures uniform strip tension, reducing forming defects.

-

Strong adaptability: Suitable for various materials and strip thicknesses.

-

Moderate footprint: Saves about 30% of space compared to traditional horizontal accumulators.

5. Comparison Between Cage Accumulator and Disk Accumulator

Summary:

If ultra-high speed (150m/min and above) is required, a disk accumulator is preferred.

For standard medium-high speed tube mills, a cage accumulator is the optimal choice considering cost and reliability.

6. Cage Accumulator Selection Guide

【Notes on Selection】

-

Strip width and thickness are the basic criteria for selecting the cage accumulator model.

-

Line speed determines whether enhanced tension control and safety features are needed.

-

Factory layout restrictions and surface protection needs should be communicated early for tailored designs.

-

For cost-performance balance, the standard medium-duty cage accumulator is recommended for most ERW production lines.

COGNATIO ORNATUS

Nos omnem apparatum praebet ad sectionem molendini tubi viscus:

Coil Car

Singula et duplicata capita Un-coiler & hydraulica et pneumatica Un-coiler

Peeler et tenere in volumine arm

Machina adulatione

Automatic et Semi Auto Shearer & Butt Welder

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

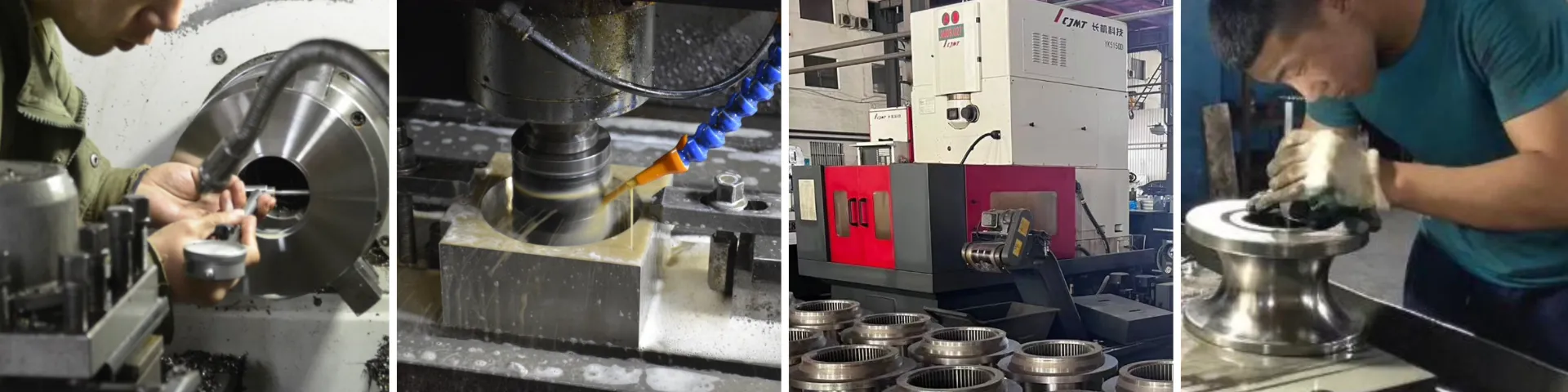

OPERA NOSTRA

Quid nos elige?

Ducens Technology, Reliable Quality, Excellent Service!

Optimized Design, High quality material select!

Caloris curatio processus spondet!

Calces cochleae revellere, orum calces copulatio et carburization.

Dentium calces exstingui.

Ratio acti stabilis, efficax et infatigabilis cum sonitu inferiori.

Summa subtilitate gerunt resistendo et longam tribulis vitam.

Tota machina Lathes, sulci Clavis a CNC cincta et molita sunt.

Post-Sales ministerium

1. Nos machinam trademus et documenta in tempore praebebunt ut machinam celeriter efficere possis

2. Praeparatio condiciones cum consummaveris, Ieiunium et professio nostra postsales servitii fectum ibit ad officinam tuam ut machinam instituat, manualem operantem tibi tribuat, et operarium tuum exerceat donec machinam bene operari possint.

3. Nos unum annum warantum et diuturnum technicum subsidium praebent.

4.Bene peritus & peritus baculus respondeat omnibus tuis quaestionibus Anglice et Sinice

5 .24 horae ad fectum responsum.

6. Negotium tuum cum nobis communicatio alicui tertiae parti secretior erit.

Qualitas Imperium

Unicum qualitatem habemus, quae materiam rudium materiarum bonam fac, et machinam nonumyter curet.

Tel:86-15176910262

Tel:86-15176910262