-

Tel:86-15176910262

Tel:86-15176910262

-

Aramak

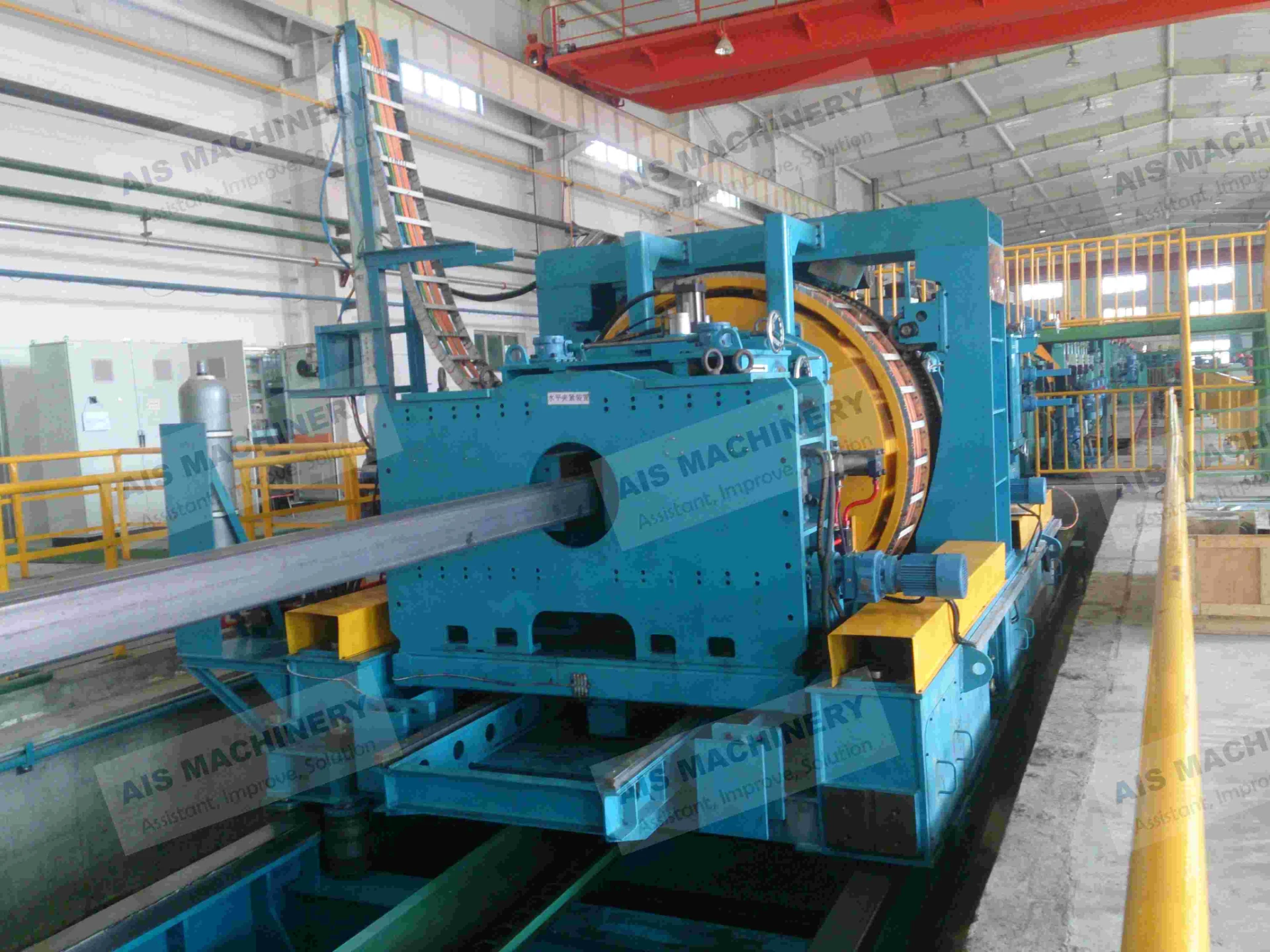

ERW Karbon Çelik Boru Fabrikası

What is ERW TUBE MILL?

ERW TUBE MILL is a specialized manufacturing system designed to transform flat steel strips into tubes through a continuous process. Using high-frequency welding (HFW), this technology joins the edges of the steel strip to form a longitudinal seam, creating a tube with excellent structural integrity. These mills are highly automated, significantly reducing the need for manual intervention. They feature precise control over tube dimensions, ensuring that each product meets exact specifications with minimal variation. Furthermore, the consistent and efficient operation of ERW tube mills supports high-volume production, making them ideal for industrial-scale manufacturing. ERW tube mills are integral to many sectors, including construction, automotive, energy, and infrastructure, where they produce a variety of welded steel tubes used in diverse applications.

Tube Mill Production Process

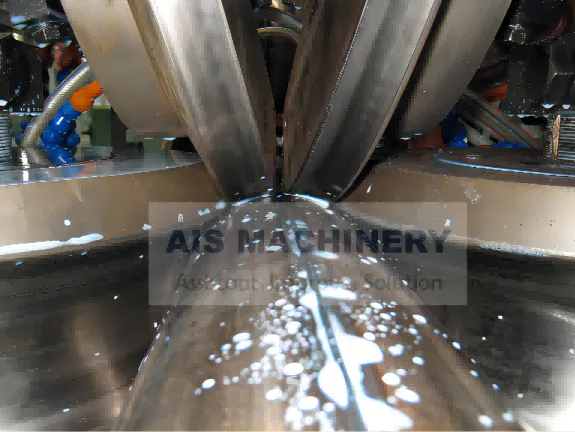

The process begins with high-quality steel strips—either coil or sheet form—being steadily fed into the forming section of the machine. As the material moves forward, a carefully engineered series of forming rollers gradually shape it into a round tube profile, preparing it for welding without inducing excess stress or deformation. Next, the strip edges are welded using high-frequency induction welding, a clean and efficient method that creates a strong longitudinal weld without additional filler material. This welding process ensures seam structural integrity, making it suitable for demanding industrial applications. After seam welding, the tube undergoes sizing and straightening, where other rollers precisely calibrate the tube to the target dimensions and cross-sectional form—whether round, square, or rectangular. This ensures exceptional dimensional consistency and surface straightness. Once the shape is achieved, an automated Cutoff system cut the tube into pre-set lengths without stopping production, enabling high-speed, continuous output.

In order to solve the problem of pipe straightness, we innovatively selected 3 straightening Turkish heads and equipped them with 11-roller steel pipe straightening machines to control the straightness within 0.05%. We treat our products with almost rigorous technology.

For example, the 5-inch welded pipes for solar brackets provided by our company to NEXTRACKER customers in the United States use precise technology to ensure the perfection of the welds and the standard of the straightness of the steel pipes, which are recognized by customers.

Our equipment has been approved by Canada's CSA, and has passed international certifications such as CE and ISO, as well as laboratory-level requirements, waiting for customers to experience.

What are ERW tubes used for?

ERW TUBE are widely used in the construction field, transportation industry, automobile industry, solar energy and agricultural infrastructure construction. Such as building frames, scaffolding, safety fences, transportation of oil, natural gas, tap water, API conduit tube, API casing tubing, solar piles, furniture, greenhouse support frame and agricultural pipeline systems.

Mesaj Gönder

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!