-

Tel:86-15176910262

Tel:86-15176910262

-

Search

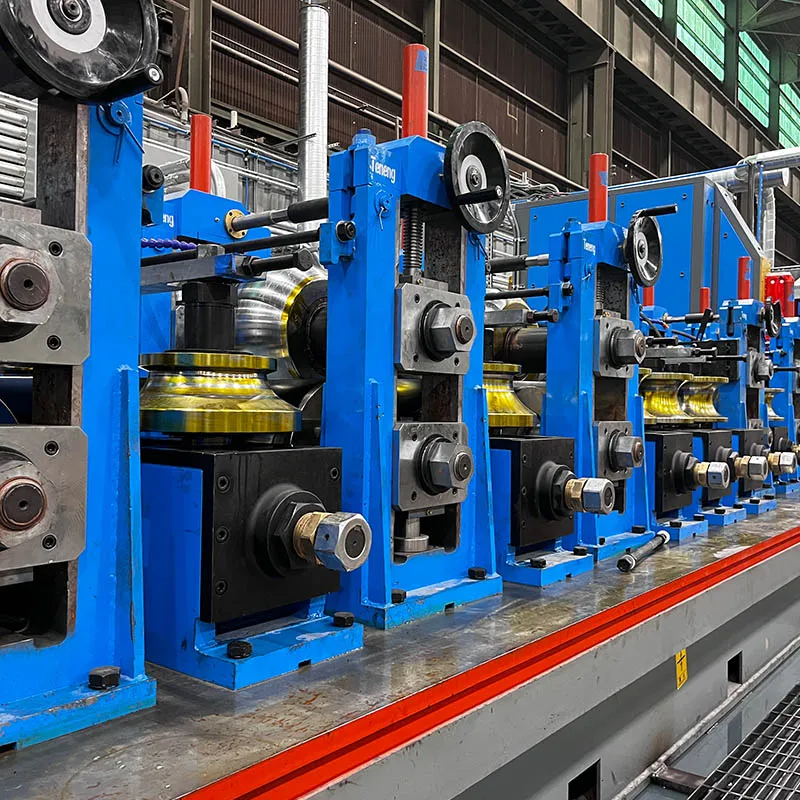

168mm 6inch ERW High Speed Tube Mill from China Manufacturer

Mar . 07, 2025 05:28

High frequency pipe mills have revolutionized the manufacturing landscape by offering efficient and reliable solutions for producing high-quality pipes. As an experience-driven product, the high frequency pipe mill effectively combines cutting-edge technology with hands-on expertise to deliver consistent results in pipe production. This article delves into the intricacies of high frequency pipe mills, emphasizing their role in modern manufacturing and their contribution to the industry in terms of expertise, authoritativeness, and trustworthiness.

The authoritativeness of high frequency pipe mills is bolstered by endorsements and certifications from reputable industry bodies, attesting to their capability and compliance with international standards. Manufacturers who employ these mills frequently pursue ISO certification, further cementing their commitment to quality and reliability. Such certifications are not only indicative of the product's quality but also of the competency of the personnel operating the machinery, reflecting the high level of training and skill involved. Trustworthiness in high frequency pipe mills is evident in the long-term reliability and performance of the products they produce. Clients and industry partners often cite the longevity and robustness of the pipes as key reasons for their continued patronage. The consistent quality output, backed by rigorous testing and quality assurance processes, provides peace of mind to customers, knowing that they are investing in a product that will stand the test of time. Moreover, the sustainability aspect of high frequency pipe mills further enhances their trustworthiness. By incorporating advanced technologies that minimize waste and maximize efficiency, these mills contribute positively to eco-friendly practices. This aligns with the growing industry trend towards sustainable manufacturing, which is becoming increasingly important to stakeholders across the supply chain. In conclusion, high frequency pipe mills represent a synthesis of experience, expertise, authoritativeness, and trustworthiness in the pipe manufacturing industry. Their advanced technology and efficient processes not only enable the production of high-quality pipes but also provide tangible benefits in terms of cost savings, environmental sustainability, and product reliability. As industries continue to evolve and demand greater precision and efficiency, high frequency pipe mills remain at the forefront, offering solutions that meet and exceed these expectations.

The authoritativeness of high frequency pipe mills is bolstered by endorsements and certifications from reputable industry bodies, attesting to their capability and compliance with international standards. Manufacturers who employ these mills frequently pursue ISO certification, further cementing their commitment to quality and reliability. Such certifications are not only indicative of the product's quality but also of the competency of the personnel operating the machinery, reflecting the high level of training and skill involved. Trustworthiness in high frequency pipe mills is evident in the long-term reliability and performance of the products they produce. Clients and industry partners often cite the longevity and robustness of the pipes as key reasons for their continued patronage. The consistent quality output, backed by rigorous testing and quality assurance processes, provides peace of mind to customers, knowing that they are investing in a product that will stand the test of time. Moreover, the sustainability aspect of high frequency pipe mills further enhances their trustworthiness. By incorporating advanced technologies that minimize waste and maximize efficiency, these mills contribute positively to eco-friendly practices. This aligns with the growing industry trend towards sustainable manufacturing, which is becoming increasingly important to stakeholders across the supply chain. In conclusion, high frequency pipe mills represent a synthesis of experience, expertise, authoritativeness, and trustworthiness in the pipe manufacturing industry. Their advanced technology and efficient processes not only enable the production of high-quality pipes but also provide tangible benefits in terms of cost savings, environmental sustainability, and product reliability. As industries continue to evolve and demand greater precision and efficiency, high frequency pipe mills remain at the forefront, offering solutions that meet and exceed these expectations.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!