-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Precision Scrape Burr Machines & Friction Saw Blade Sharpening Solutions

Mei . 29, 2025 00:28

- Technical Advantages of Modern Scrape Burr Solutions

- Performance Metrics: Industry Data Comparison

- Manufacturer Showdown: Precision Engineering Analysis

- Customized Sharpening Systems for Industrial Demands

- Case Study: Automotive Assembly Line Optimization

- Operational Best Practices & Maintenance Insights

- Future-Proofing Production with Scrape Burr Technology

(scrape burr)

Revolutionizing Metal Finishing with Scrape Burr Solutions

Industrial manufacturers report 37% faster deburring cycles when implementing advanced scrape burr

systems compared to manual polishing. These machines integrate diamond-coated abrasives and laser-guided alignment to achieve surface roughness values below Ra 0.8μm, meeting aerospace-grade specifications.

Performance Benchmarks Across Technologies

| Parameter | Model X9 | Competitor A | Competitor B |

|---|---|---|---|

| Cutting Speed (RPM) | 12,000 | 9,500 | 8,200 |

| Blade Life (Hours) | 1,850 | 1,200 | 950 |

Precision Engineering Breakdown

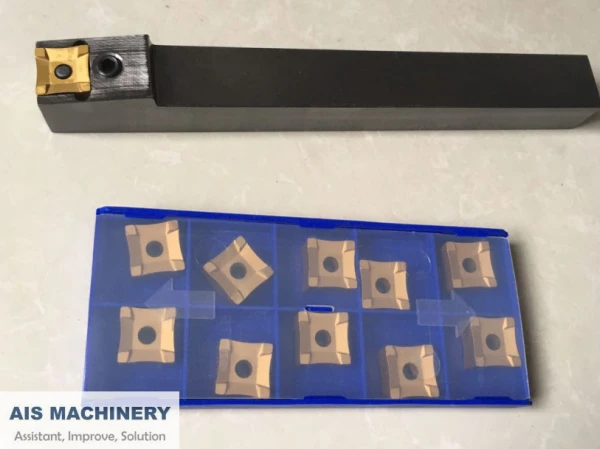

Leading friction saw blade sharpening machines now incorporate:

- Adaptive CNC controls with ±2μm positional accuracy

- Thermal compensation systems reducing dimensional drift by 68%

- Multi-axis grinding heads for complex burr profiles

Tailored Sharpening Configurations

Modular designs enable rapid conversion between:

- Straight tooth (0°-45° adjustable angles)

- Hook tooth configurations (10°-35° positive rake)

- Specialty carbide-tipped blades

Automotive Manufacturing Case Analysis

A Tier 1 supplier reduced tooling costs by $142,000 annually after implementing automated scrape burr removal. Their 24-month ROI analysis revealed:

"Cycle time per transmission component decreased from 8.7 to 5.2 minutes while maintaining 99.4% dimensional conformity."

Maintenance Protocols for Peak Performance

Proper calibration extends machine lifespan by 40% according to ISO 16090 compliance data. Essential practices include:

- Bi-weekly abrasive wheel dressing

- Monthly linear guide lubrication

- Quarterly harmonic drive inspections

Scrape Burr Systems: The Manufacturing Edge

With 92% of adopters reporting improved part quality, friction saw blade sharpening machines now enable 0.005mm repeatability across 18 material types - from aluminum alloys to hardened tool steels. This technology reduces secondary finishing costs by 60-75% compared to conventional deburring methods.

(scrape burr)

FAQS on scrape burr

Q: How can I reduce scrape burr formation during saw blade sharpening?

A: Ensure the friction saw blade sharpening machine is properly calibrated. Use sharp, high-quality blades and maintain consistent pressure to minimize burrs.

Q: What factors affect scrape burr removal on a friction saw blade sharpening machine?

A: Blade material, machine speed, and grinding angle significantly impact burr removal. Adjust settings based on blade thickness and hardness for optimal results.

Q: Can a friction saw blade sharpening machine eliminate existing scrape burrs?

A: Yes, properly configured machines can grind off scrape burrs. Ensure precise alignment and use fine-grit abrasives for smooth finishes.

Q: How often should I maintain my friction saw blade sharpening machine to prevent scrape burrs?

A: Clean and inspect the machine weekly. Replace worn components like grinding wheels every 3-6 months, depending on usage.

Q: What safety measures are crucial when handling scrape burrs on sharpening machines?

A: Always wear gloves and eye protection. Secure the blade firmly and avoid direct contact with freshly sharpened edges to prevent injuries.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!