Video

Tube Mill SPUB OD Scrarfing Inserts/ External Bead Removing Tool

Tube Mill SPUB OD Scrarfing Inserts/ External Bead Removing Tool

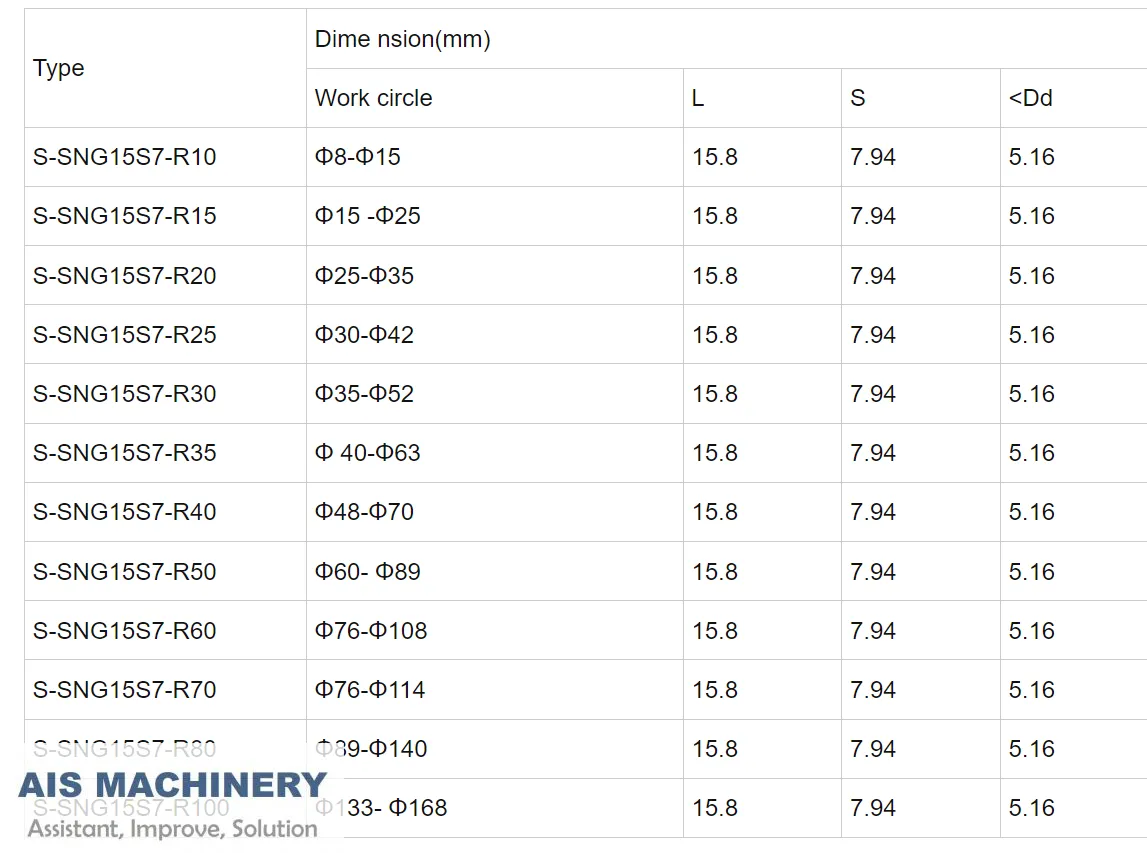

We stock a full line of 4-sided OD Tube Mill SPUB OD Scrarfing Inserts, 6 sided, 8 sided, will different size.

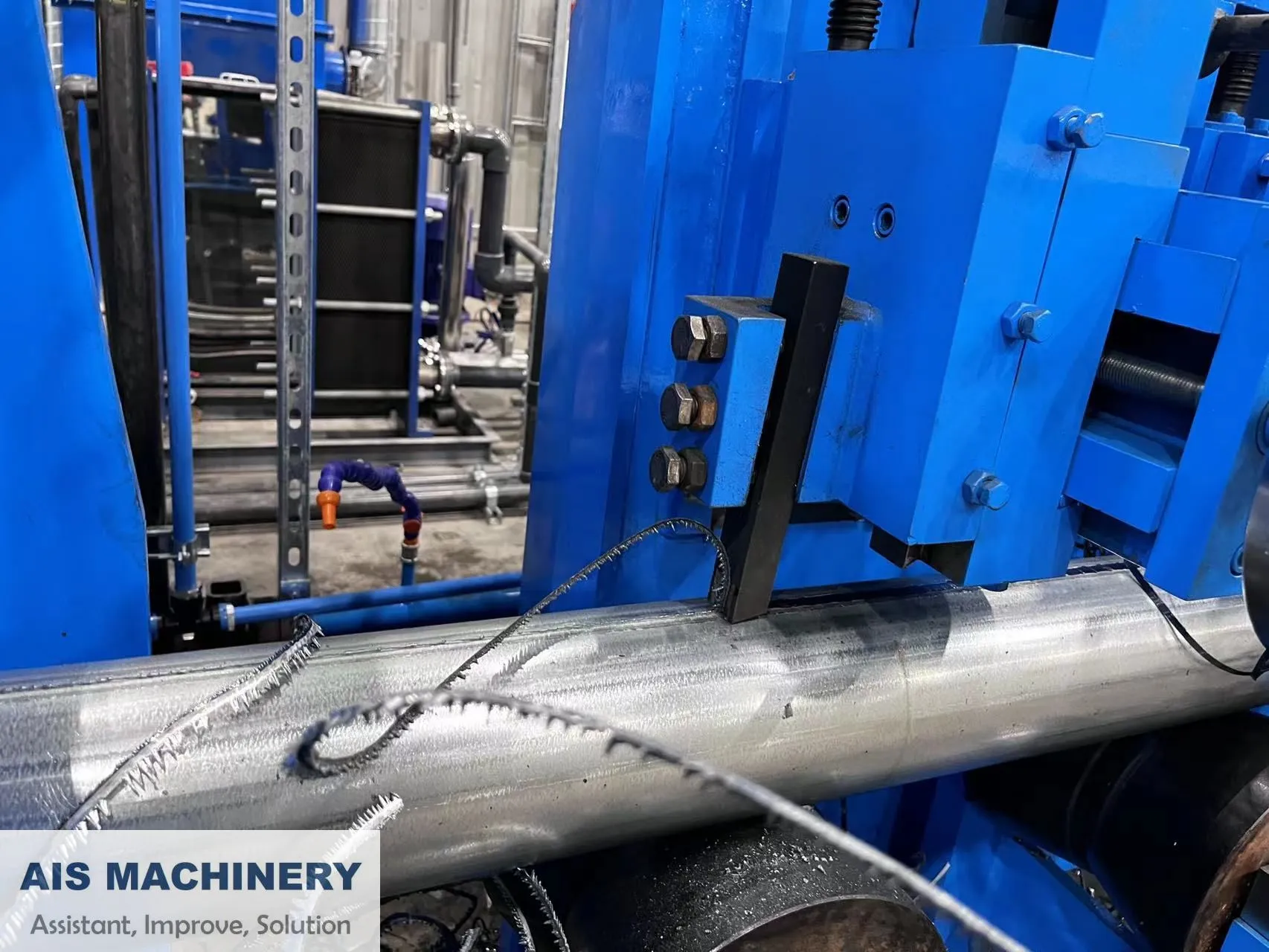

Remove outside burr Device (scrafing winder):

It is used to scrap weld seam and remove external burr. It is made up of two cutters for using alternately, if one is wrong, another can be changed, and scraper can be adjusted for up or down, and it can disappearing end bumper quickly by cam. There are two supporting roller underneath knife rest for bear scraping pressure.

Tube Mill Scarfing Inserts

AIS MACHINERY stocks many variety of OD scarfing tools in the industry! This gives you access to a wide variety of tools at a moments notice. We stock a full line of “63” series 4-sided OD scarfing tools, 6-sided OD scarfing tools, and various common sizes in 4-sided OD scarfing tools and 3 sided tube chamfering tools for your tube scarfing application.

OD Scarfing Tools | Scarfing Inserts | Tool Holders

AIS MACHINERY scarfing tools and related products are superior, longer lasting, and will help increase your tube and pipe production. Our engineering and manufacturing processes produce great tools with a unique modular design that are both easier to install and disassemble. We can help you reduce scarfing downtime and give you better customization options in your production process.

Give us a call to order our tube scarfing products. You’ll be more than convinced you’ve made the right choice. Our complete ID-scarfing and OD-scarfing systems consist of all of the components you’ll need for high-efficiency tube and pipe production.

We pursue excellence and meet the real and potential needs of our customers with high quality Tungsten Carbide CNC Inserts, Inside Tube Scarfing Tools.The pursuit of External Scarfing Tool excellence is our unswerving goal and our commitment to our customers and society!

Super fast scarfing tool shipment:

Whether your end product is a 5/8” OD tube, 12” OD tube, or anywhere in between,we can handle your tube size. This wide selection of tools gives you a one-stop shop for all your OD scarfing tool and carbide needs.

Titanium Nitride and Aluminum Oxide coated Scarfing Tools in stock:

We offers you a choice in OD scarfing tool coatings for different scarfing applications. These coatings allow you to have the right product for your application whether it is a high speed, high heat application or the run of the mill tube scarfing job.

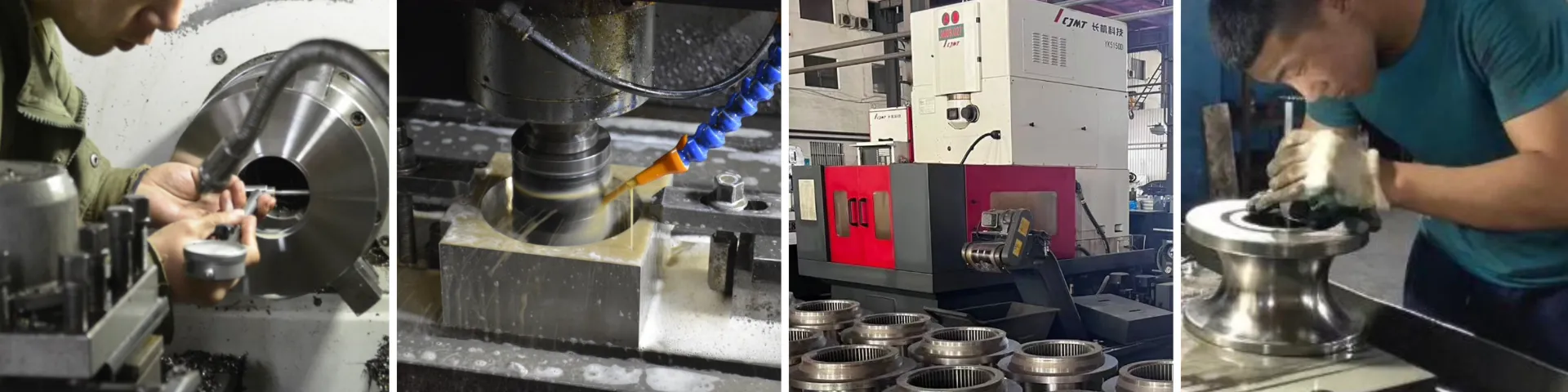

1. Rich production experience: We specialize in the research and development and production of special tools for the welded pipe industry. With rich time experience, we can tailor the exclusive products for your needs.

2. Complete production facilities: advanced equipment such as coating equipment imported from Switzerland, CNC grinder, ultrasonic cleaning machine for machine tools and so on. Our technicians will perform regular maintenance on these machines to ensure their normal operation.

3. High-quality raw materials: We mainly use raw materials from large steel mills, which are the best and largest raw material manufacturers in China.

4. Strict quality inspection procedures: meet product design and process requirements, and provide reliable testing data.

-

1. Coil Car and Storage

-

2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

-

3.Peeler and hold down roll arm

-

4.Flattening Machine

-

5.Automatic and Semi Auto Shearer & Butt Welder

-

6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

1. Eddy current machine

-

2. Seam annealing machine

-

3. Straightener machine

-

4. Chamfer and end facer machine

-

5. Hydro Tester machine

-

6. Threading machine

-

7. Painting and oil machine

-

8. Automatic bundle and package machine

Spare Parts and Consumble Parts

-

1. Rollers, Moulds, Dies, D2, D3 material to choose

-

2. Ferrite, Impeder, Fiberglass tube

-

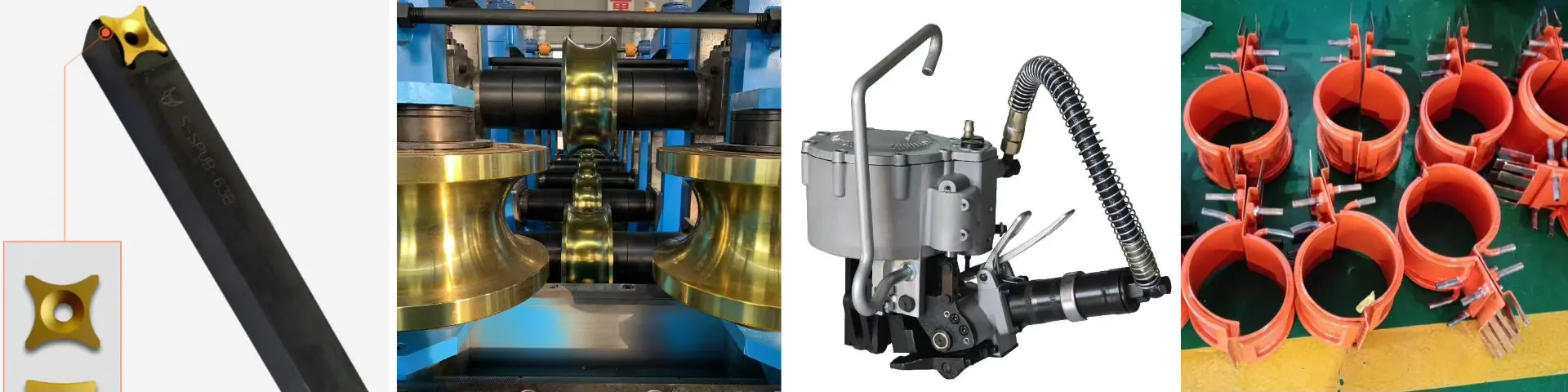

3. HSS saw blades, TCT Saw blades, Friction saw blades

-

4. OD burr remove inserts, ID burr remover inserts

-

5. HF welder Induction Coil and other HF welder spare parts

-

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

-

7. Mosfet, Boards

-

8. Steel pipe Strapping machine

-

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

- Why Choose Us?

-

1.Leading Technology, Reliable Quality, Excellent Service! Optimized Design, High quality material select! Heat treatment process guarantee!

-

2.Spiral bevel gear, drum gear coupling and carburization. Gear teeth quenching. Driven system stable, efficient and wearable with lower noise.

-

3.High precision wear resisting and Long life of toolings. All the machine Lathes, Key Grooves are positioned and Milled by CNC.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

After-sales service

-

1.Machine test running videos will supply to customer before shipment.

-

2.Online techenical support WHOLE LIFT FREE.

-

3.Professional engineers team to install the machine, train your employee well.

-

4.One year warranty and life-long technical support.

-

5 .24 hours for engineer response.

-

6.Your business relationship with us will be confidential to any third party.

-

7. We welcome customers to visit our factory anytime.

Tel:86-15176910262

Tel:86-15176910262